INSPECTION

/

REPAIR

f-6t'1

L'----\-v

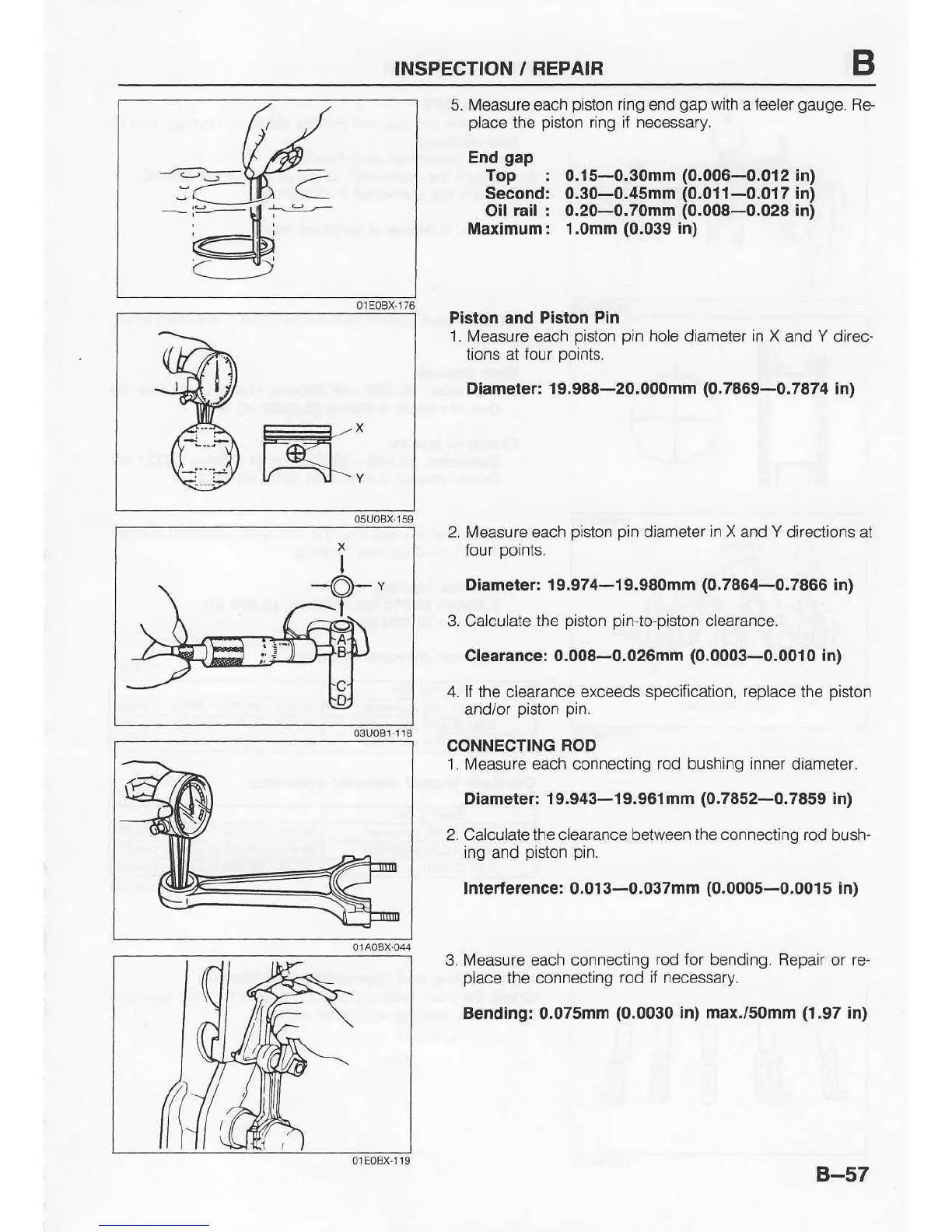

5. Measure each

pislon

ring end

gap

with a

feeler

gauge.

Re-

place

the

piston

ring if necessary.

Erd

gap

Top : 0.15-0.30mm

(0.006-0.012

in)

Second: 0.30-0.45mm

(0,011-0,017

in)

Oil

rail : 0.20-0.70mm

(0.008-0.028

in)

Maximum: 1.omm

(0.039

in)

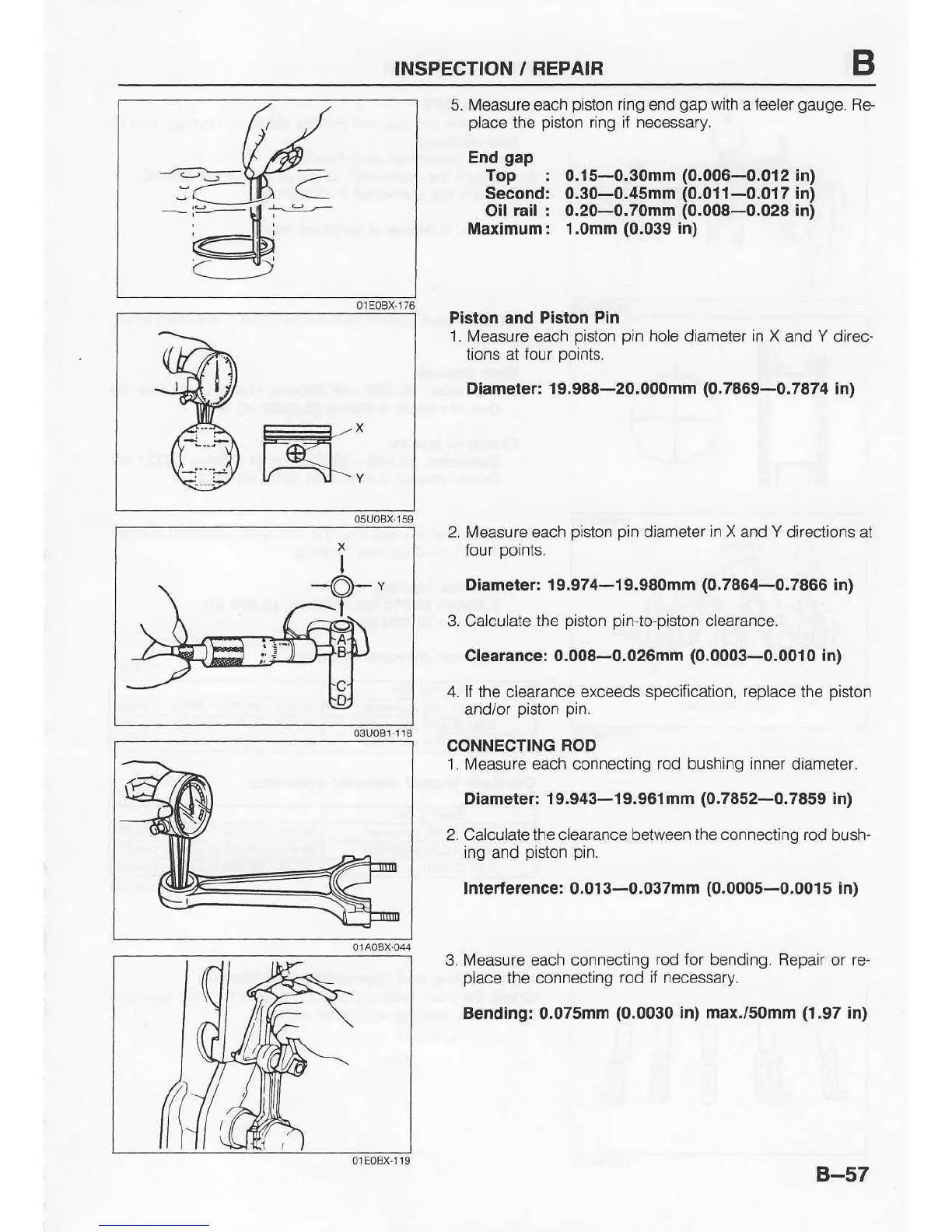

Piston and Piston

Pin

1.

Measure each

piston pin

hole diameter in X

and Y direc-

tions at lour

points.

Diameier: 19.988-20.000mm

(0-7869-0.7874

in)

2. Measure each oiston oin diameler

in X

and Y directions ai

four

points.

Diameter:

19.974-19.980mm

(0.7864-0.7866

in)

3. Caiculate

the

oiston Din{eoiston clearance.

Clearance:

0,008-0.026mm

(0.0003-0.0010

in)

4. Il

the clearance

exceeds specification, replace

the

piston

and/of oiston oin.

CONNECTING

ROD

1. Measure each connecting

rod

bushing

inner

diameter.

Diameter:

19.943-19.96lmm

(0.7852-0.7859

in)

2. Calculatethe

c/earance

between

the connectino rod

bush-

ing and

piston pin.

Interterence: 0.013-0.037mm

(0.0005-0.0015

in)

3. Measure each connecting

rod for bending. Repair

or

re

place

the

connecting

rod if necessary.

Bending.'

0.075mm

(0.0030

in) max./somm

(1.97

in)

B-57

Loading...

Loading...