CARBURETOR/FUEL PUMP

Page 3A-16 90-826883R2 JUNE 1998

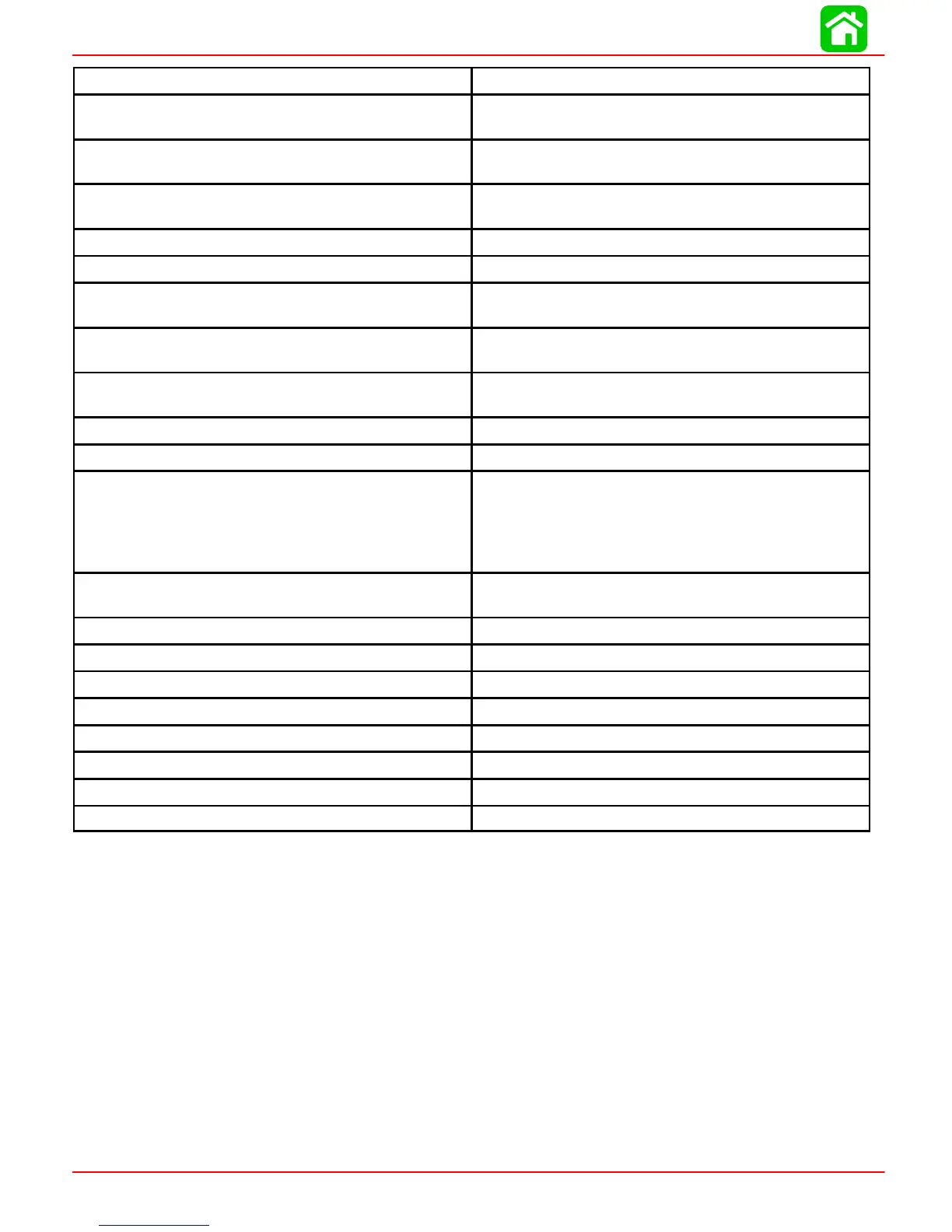

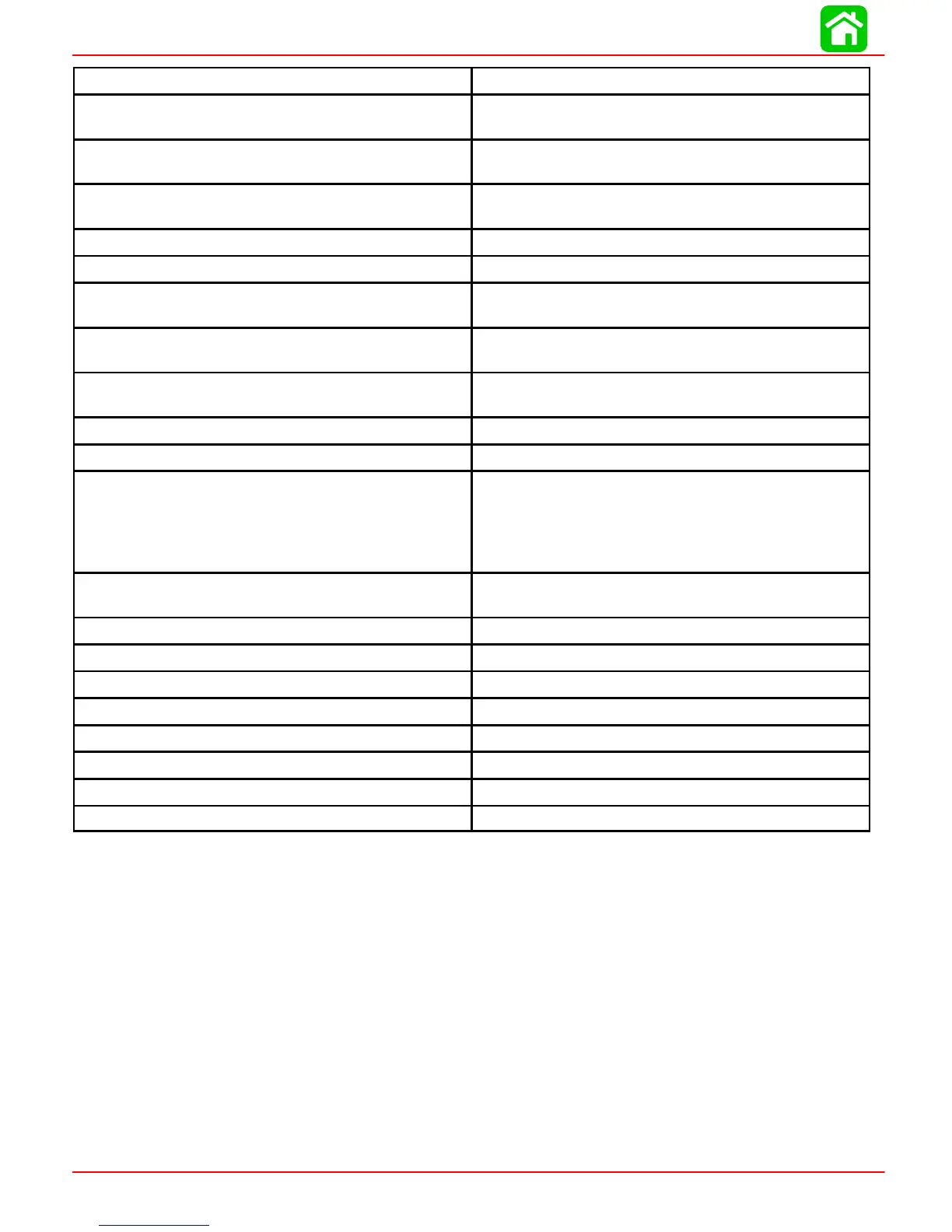

Possible Cause Corrective Action

Improperly mixed fuel. Contaminants(water, dirt,

etc.) in fuel.

Check fuel in tank and replace if necessary.

Fuel tank air vent closed or restricted. Check air vent on tank. Vent must be open all-the-

way and free from any contaminants.

A pinched, cut or restricted fuel line. Also loose

fuel line connection.

Inspect all fuel lines and replace as needed. In-

spect and tighten all fuel line connections.

Dirty or restricted fuel filter. Inspect and replace or clean all fuel filters.

Low fuel pump pressure. Disassemble and inspect fuel pump components.

Defective anti-siphon valve. Inspect valve and/or test engine without valve in

fuel system.

Needle and seat in carburetor that is either stuck

open or closed.

Refer to carburetor adjustments in this section.

Improper carburetor jet, restricted jet or idle mix-

ture screw out of adjustment.

Refer to carburetor adjustments in this section.

Improper float level. Refer to carburetor adjustments in this section.

Carburetor loose on intake manifold. Check tightness of carburetor nuts.

Reed block loose or gasket defective. Using a pressure oil can, apply 2-cycle oil around

reed block housing/crankcase housing matching

surfaces and carburetor base. If engine RPM

changes, tighten bolts/nuts or replace gaskets as

required.

Improperly routed or restricted bleed hose(s). Refer to bleed hose routing in “Powerhead” sec-

tion.

Damaged fuel pump diaphragm. Disassemble and inspect fuel pump components.

Carburetor mixing chamber cover leaking air. Tighten screws or replace gasket.

Off idle holes plugged. Blow with compressed air.

Main nozzle or idle nozzle air bleed holes plugged. Blow with compressed air.

Damaged reeds.

Refer to Section 4 for reed inspection.

Fuel pick-up outlet tube in fuel tank cracked. Replace

Wrong spark plug or improper spark plug gap Install correct plug or readjust gap.

Improper spark timing. Reset timing to correct specifications.

Loading...

Loading...