POWERHEAD

Page 4-32 90-826883R2 JUNE 1998

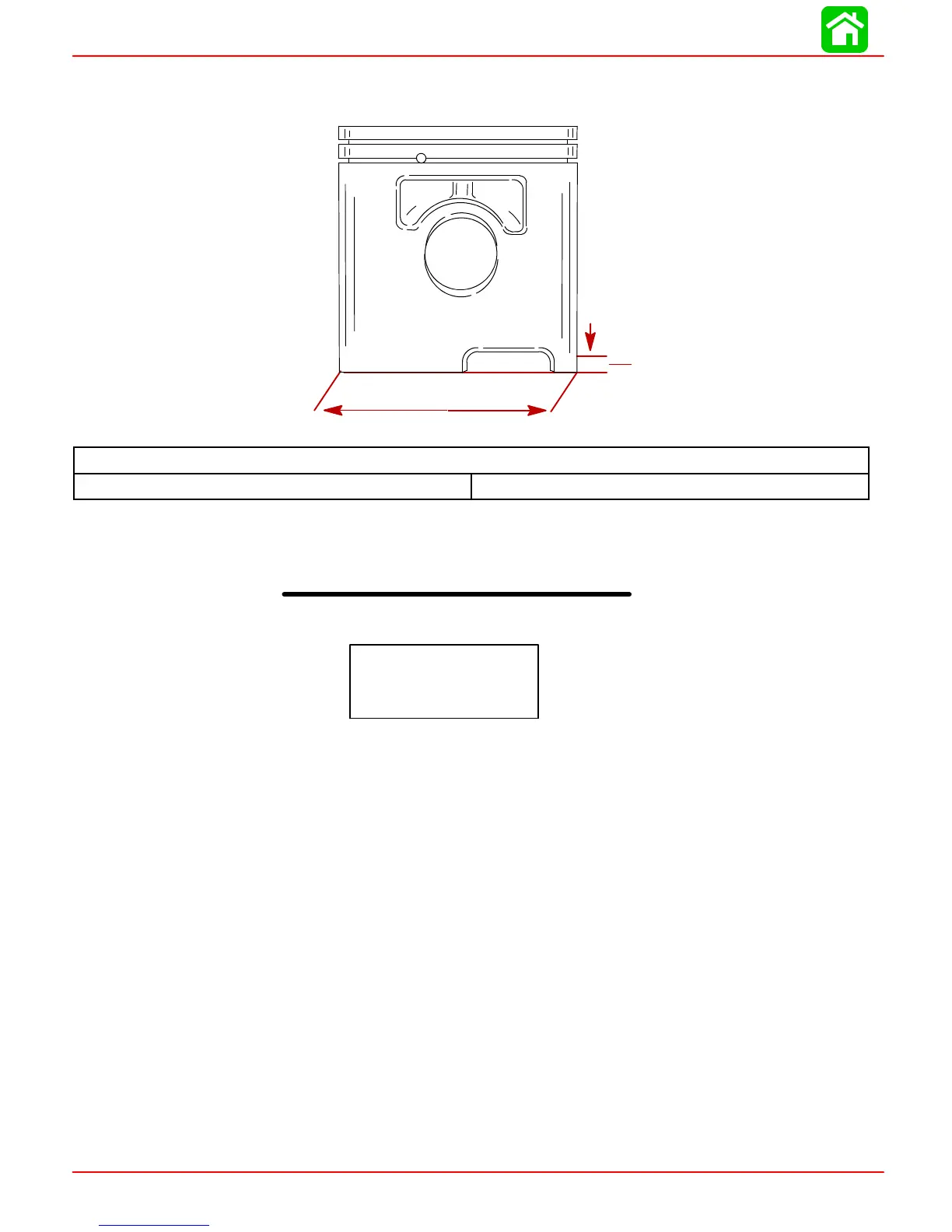

MEASURING PISTON

1. Measure piston skirt at right angle (90°) to piston pin centerline.

0.50 in.

(12.7mm)

57106

Standard Piston Diameter

20/25/20 JET 2.5583 in-- 2.5593 in. (64.98 mm -- 65.00 mm)

PISTON CLEARANCE

MINIMUM BORE MEASUREMENT

-- MAXIMUM PISTON MEASUREMENT

= PISTON CLEARANCE

PISTON CLEARANCE

0.003 in. -- 0.004 in.

(0.076 mm -- 0.101 mm)

Reed Block

IMPORTANT: DO NOT remove reeds from reed block except for inspection pur-

poses only. DO NOT turn used reeds over for reuse. If a reed block component is

damaged, the entire reed block assembly must be replaced. Individual compo-

nents are not sold separately.

1. Thoroughly clean reeds and reed block.

2. Check for wear (indentations), cracks or grooves on sealing surfaces of reed block

that could cause leakage.

3. Check for chipped or broken reeds.

4. Inspectreedblocksealforswellingorlooseness.Replacereedblockassemblyifnec-

essary.

5. If reeds have been removed, retorque screws to 25 lb. in. (2.8 N·m).Check reeds as

outlined in “Reed Opening” and “Reed Stop Opening” following

Loading...

Loading...