POWERHEAD

90-826883R2 JUNE 1998 Page 4-35

Powerhead Reassembly

General Information

Before proceeding with powerhead reassembly, be sure that all parts to be reused have

been carefully cleaned and thoroughly inspected, as outlined in “Cleaning and Inspec-

tion”. Parts, which have not been properly cleaned (or which are questionable), can se-

verelydamageanotherwiseperfectlygoodpowerheadwithinafewminutesofoperation.

All new powerhead gaskets must be installed during assembly.

During reassembly, lubricate parts with Quicksilver 2-Cycle Outboard Oil whenever

2-cycleoilisspecified,andQuicksilver2-4-Cw/TeflonMarineLubricantwhenevergrease

is specified.

CAUTION

Any GREASE used for bearings INSIDE the powerhead MUST BE gasoline solu-

ble. Use only Quicksilver 2-4-C w/Teflon Marine Lubricant or Quicksilver Needle

Bearing Assembly Lubricant. The use of any other grease may result in power-

head damage.

Atorquewrenchisessentialforcorrectreassemblyofpowerhead.Donotattempttoreas-

semble powerhead without using a torque wrench.

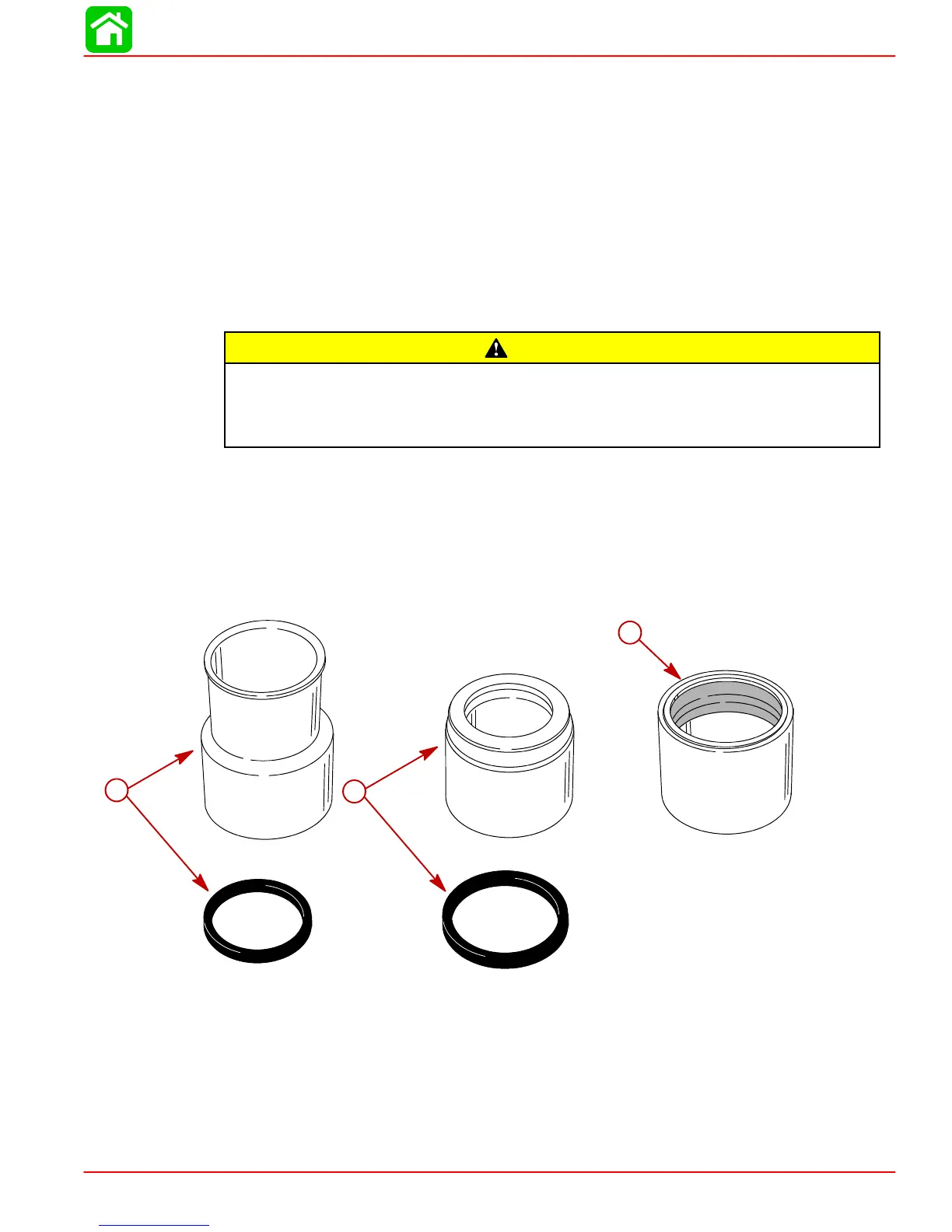

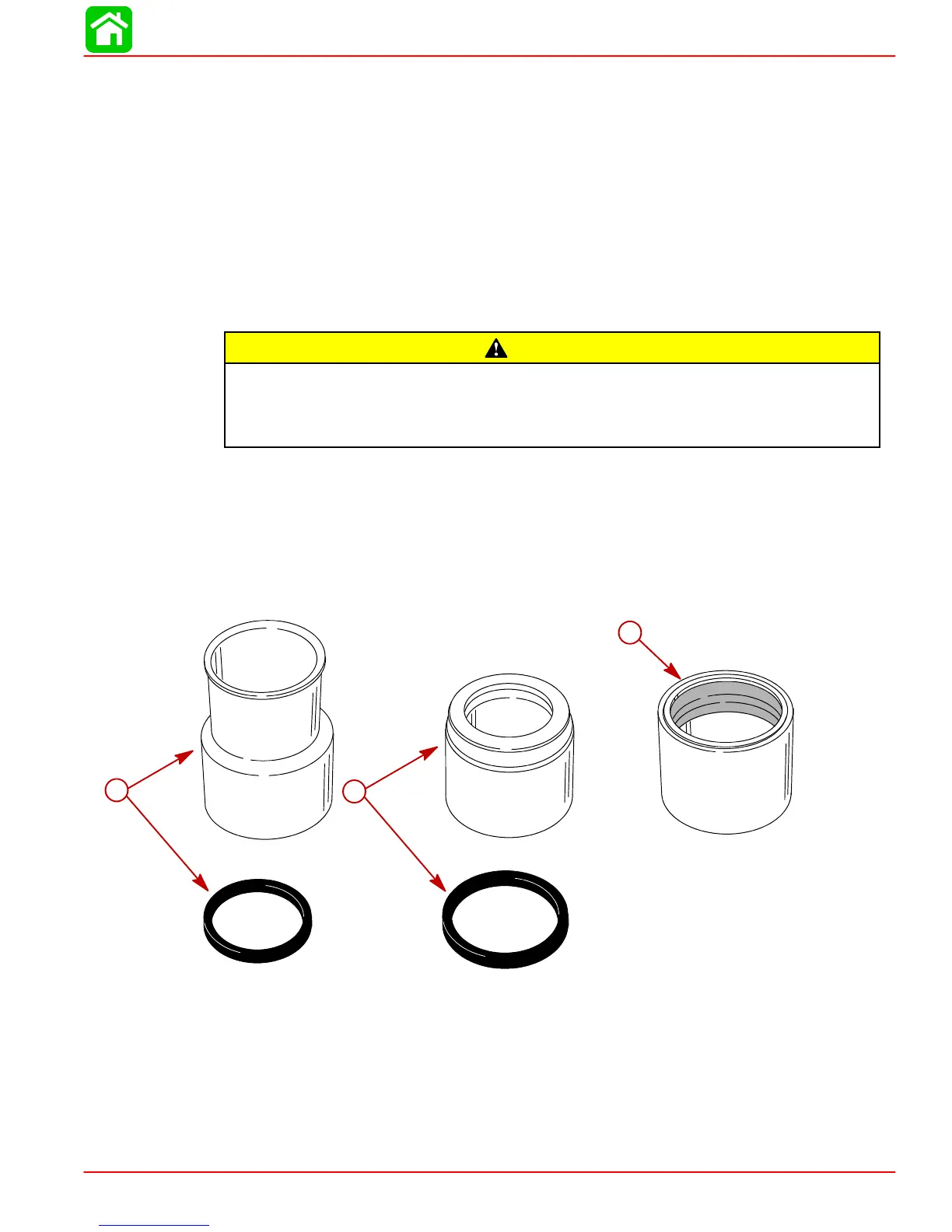

Crankshaft

NOTE: Three designs of crankshaft seals have been used. Design 3 is the current ap-

plica-

tion.

57097

a

b

c

a - Design 1 -- O-ring fits in groove on driveshaft

b - Design 2 -- O-ring fits inside of carrier

c - Design 3 -- 3 lip seal permanently installed inside of carrier

Loading...

Loading...