POWERHEAD

90-826883R2 JUNE 1998 Page 4-31

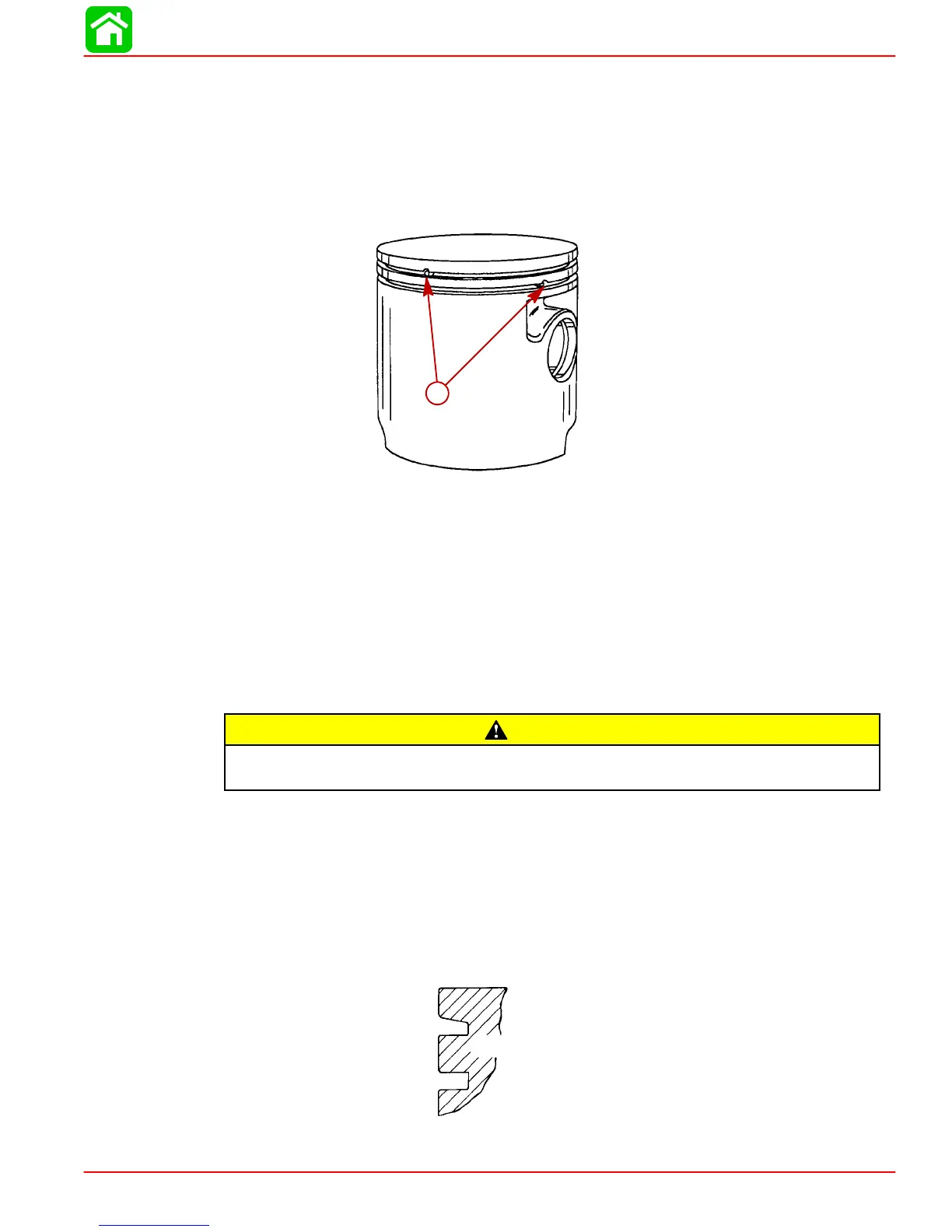

Pistons

IMPORTANT: If engine was submerged while engine was running, piston and/or

connectingrodmay bebent.If pistonpinis bent,pistonmust bereplaced.Ifpiston

pin is bent, connecting rod must be checked for straightness.

1. Inspect pistons for scoring and excessive piston skirt wear.

2. Check tightness of piston ring locating pins. Locating pins must be tight.

57105

a

a - Locating Pins

3. Thoroughlycleanpistons.Carefullyremovecarbondepositsfrompistons,withasoft

wire brush or carbon remove solution. Do not burr or round off machined edges.

Inspect piston ring grooves for wear and carbon accumulation. If necessary, scrape car-

bon from piston ring grooves being careful not to scratch sides of grooves. Refer to

procedure following for cleaning piston ring grooves.

CLEANING PISTON RING GROOVES

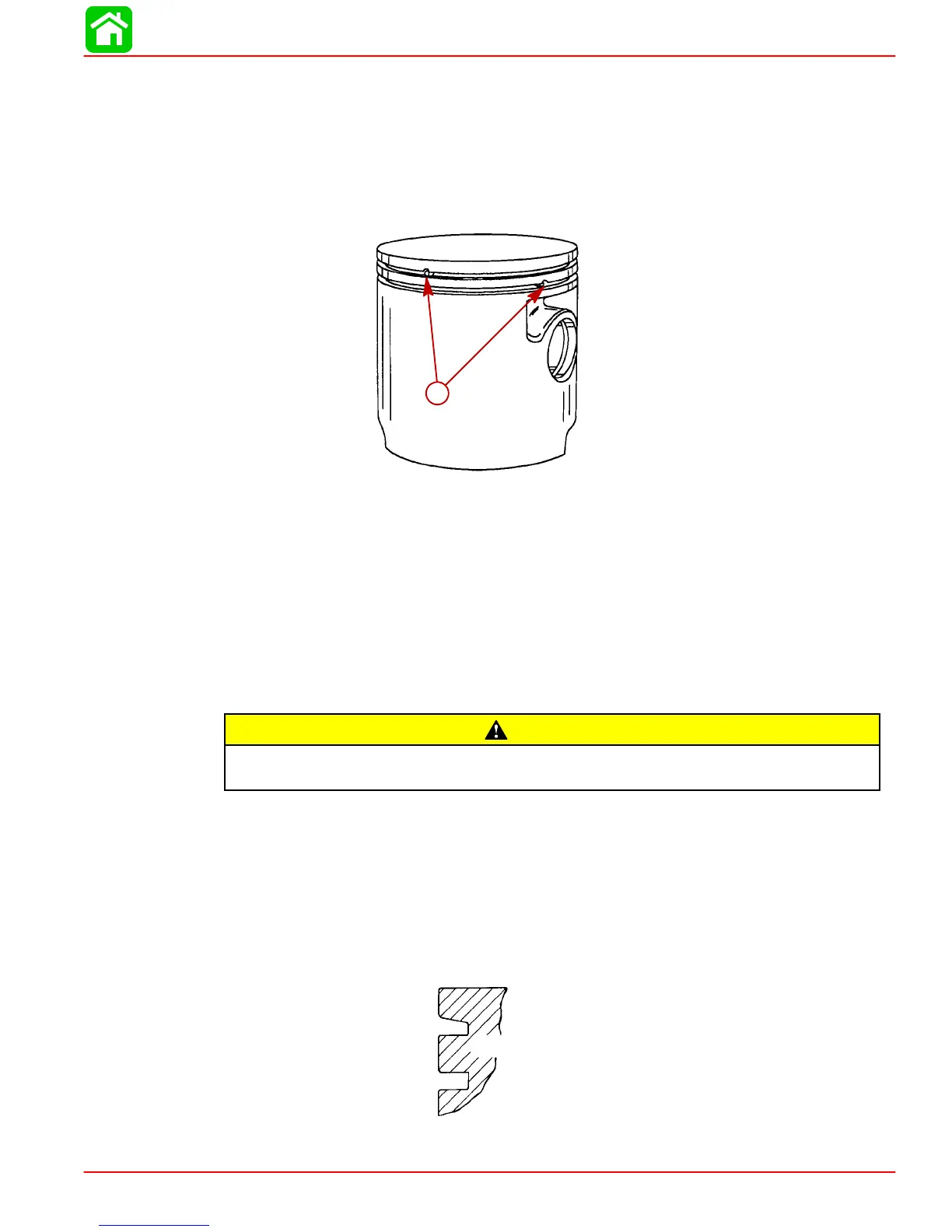

Keystone (tapered) ring grooves

CAUTION

Caremustbetakennottoscratchthesidesurfacesoftheringgroove.Scratching

the side surface of the ring groove will damage the ring groove.

1. Useabristlebrushandcarbonremoversolutiontoremovecarbonfromsidesurfaces.

2. A tool can be made for cleaning the inner diameter of the tapered ring grooves. For

thetopringgroove,atoolcanbemadefromabrokentaperedpistonringwiththeside

taperremovedtoenabletheinsideedge of the ring to reachthe innerdiameter ofthe

groove.Forthebottomringgroove,atoolcanbemadefromabrokenrectangularring.

Carefully scrape carbon frominner diameter of ringgrooves.Care must be taken not

to damage the grooves by scratching the side surfaces of the grooves.

Piston with 1 half keystone (half tapered) and 1 rectangular ring.

Loading...

Loading...