POWERHEAD

90-826883R2 JUNE 1998 Page 4-25

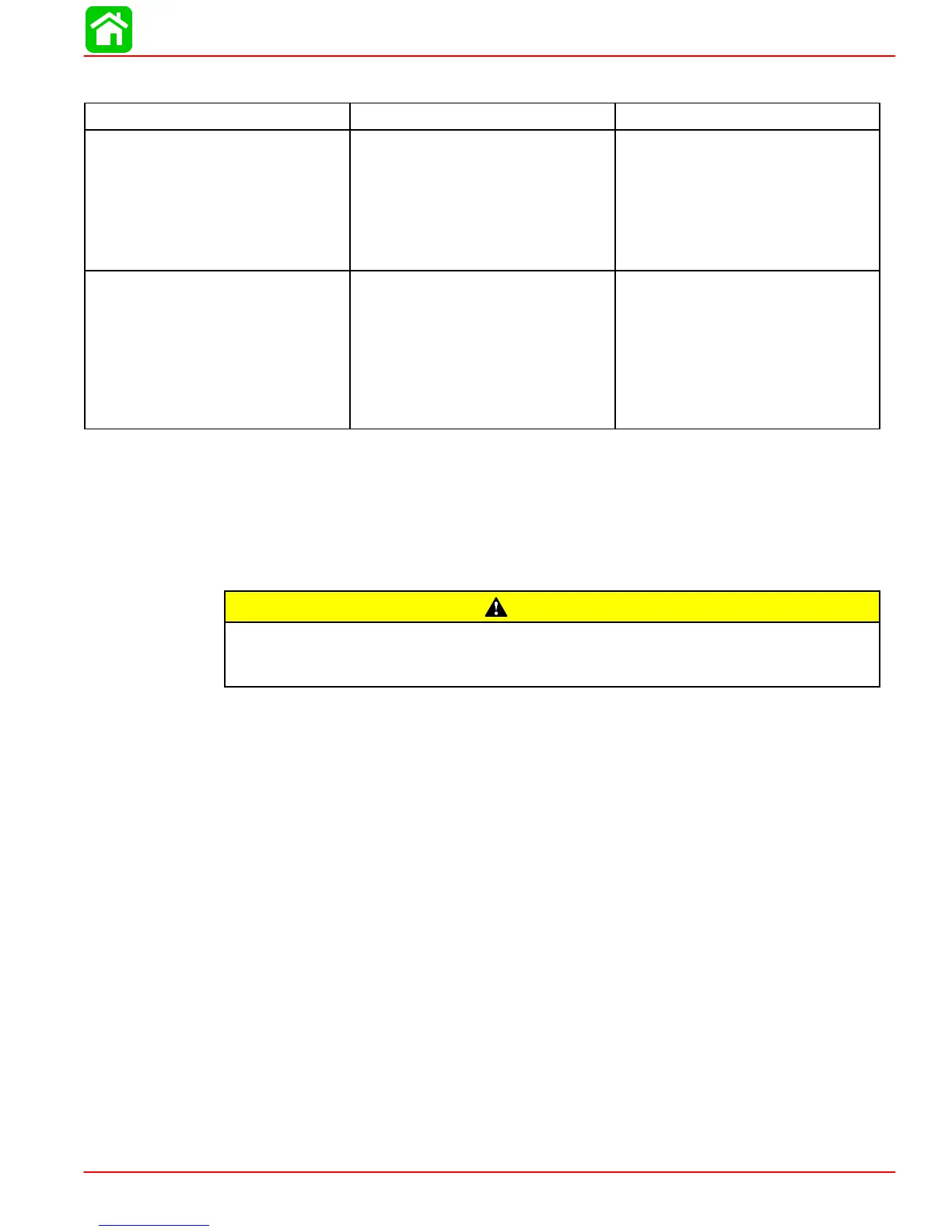

STANDARD CYLINDER BORE DIAMETER

20/25/20 JET BORE TYPE STANDARD BORE DIAMETER

ALL MODELS S/N OG202749

AND BELOW

The cylinder bores are chrome

and cannot be rebored or effi-

ciently honed. Check each cylin-

der bore for an out-of -round

“egged shaped” cylinder. A maxi-

mum of 0.003 in. (0.076 mm) is

allowable.

2.562 in. (65.01 mm)

ALL MODELS S/N OG202750

AND ABOVE

The cylinder block is Mercosil

and the cylinders can be rebored

to 0.030 in. (0.762 mm) over-

sized. Check each cylinder bore

for an out-of-round “egged

shaped” cylinder. A maximum of

0.003 in. (0.076 mm) is allow-

able.

2.562 in. (65.01 mm)

HONING PROCEDURE

a. When cylinders are to be honed, follow the hone manufacturer’s recommenda-

tions for use of the hone and cleaning and lubrication during honing.

b. For best results, a continuous flow of honing oil should be pumped into the work

area. If pumping oil is not practical, use an oil can. Apply oil generously and fre-

quently on both stones and work area.

CAUTION

Whenhoningcylinder block,remove honefrequently andcheck conditionof cyl-

inder walls. DO NOT hone any more than absolutely necessary, as hone can re-

move cylinder wall material rapidly.

c. Start strokingat smallest diameter. Maintain firm stone pressure againstcylinder

wall to assure fast stock removal and accurate results.

d. Localize stroking in the smallest diameter until drill speed is constant throughout

length of bore. Expand stones, as necessary, to compensate for stock removal

andstonewear.Strokeatarateof30completecyclesperminutetoproducebest

cross-hatch pattern. Use honing oil generously.

e. Thoroughly clean cylinder bores with hot water and detergent. Scrub well with a

stiffbristlebrushandrinsethoroughlywithhotwater.Agoodcleaningisessential.

Ifanyoftheabrasivematerialisallowedtoremaininthecylinderbore,itwillcause

rapid wear of new piston rings and cylinder bore in addition to bearings. After

cleaning, bores should be swabbed several times with engine oil and a clean

cloth, then wiped with a clean, dry cloth. Cylinders should not be cleaned with

keroseneorgasoline.Cleanremainderofcylinderblocktoremoveexcessmateri-

al spread during honing operation.

3. Hone all cylinder walls just enough to de-glaze walls.

4. Measure cylinder bore diameter (with a snap gauge micrometer) at top, middle and

bottom of each cylinder. Check for tapered, out-of-round(egg-shaped) and oversize

bore.

IMPORTANT: Ports must be deburred after honing.

Loading...

Loading...