2. CNC Monitor Screen

2.7 Diagnosis

I - 198

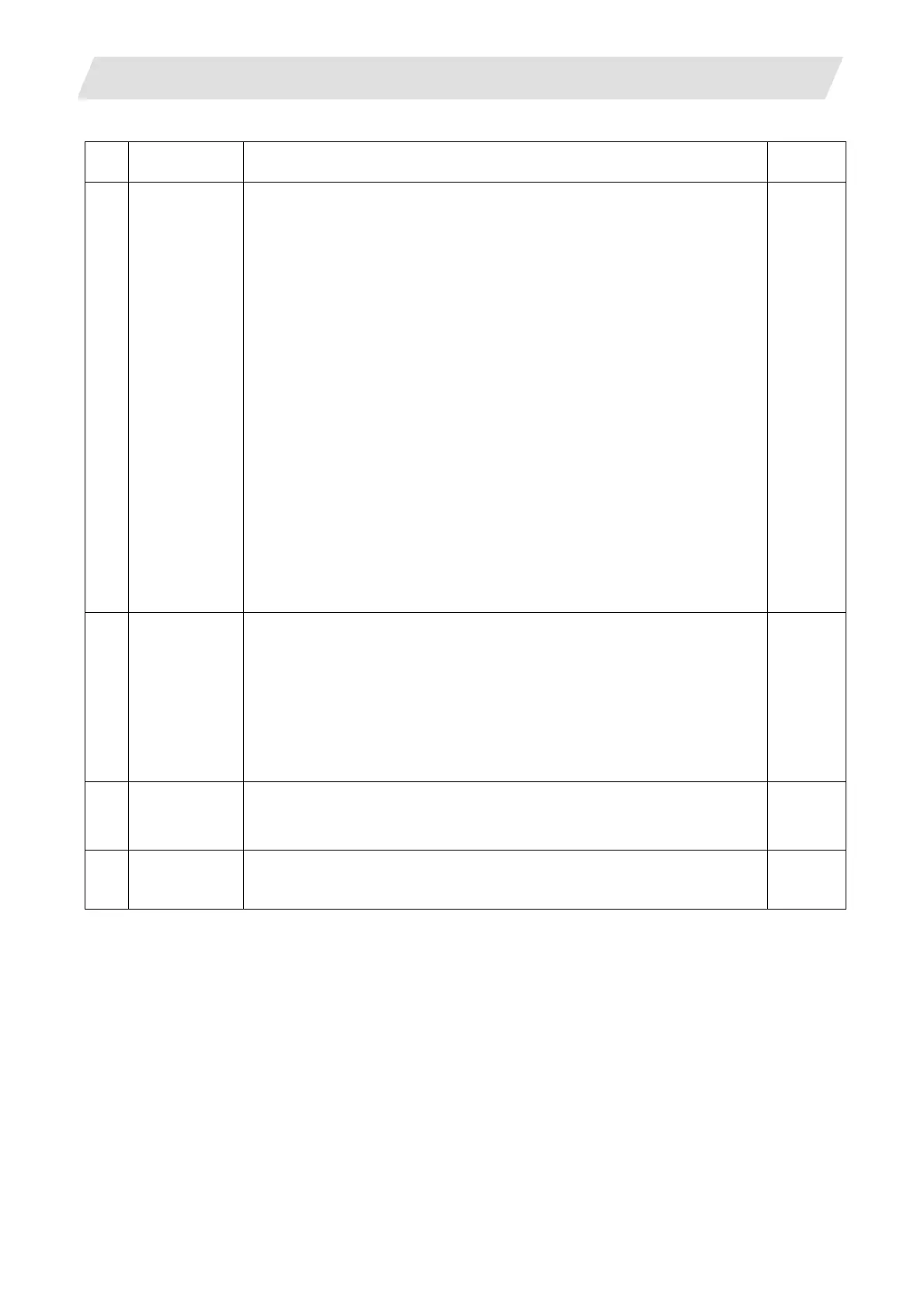

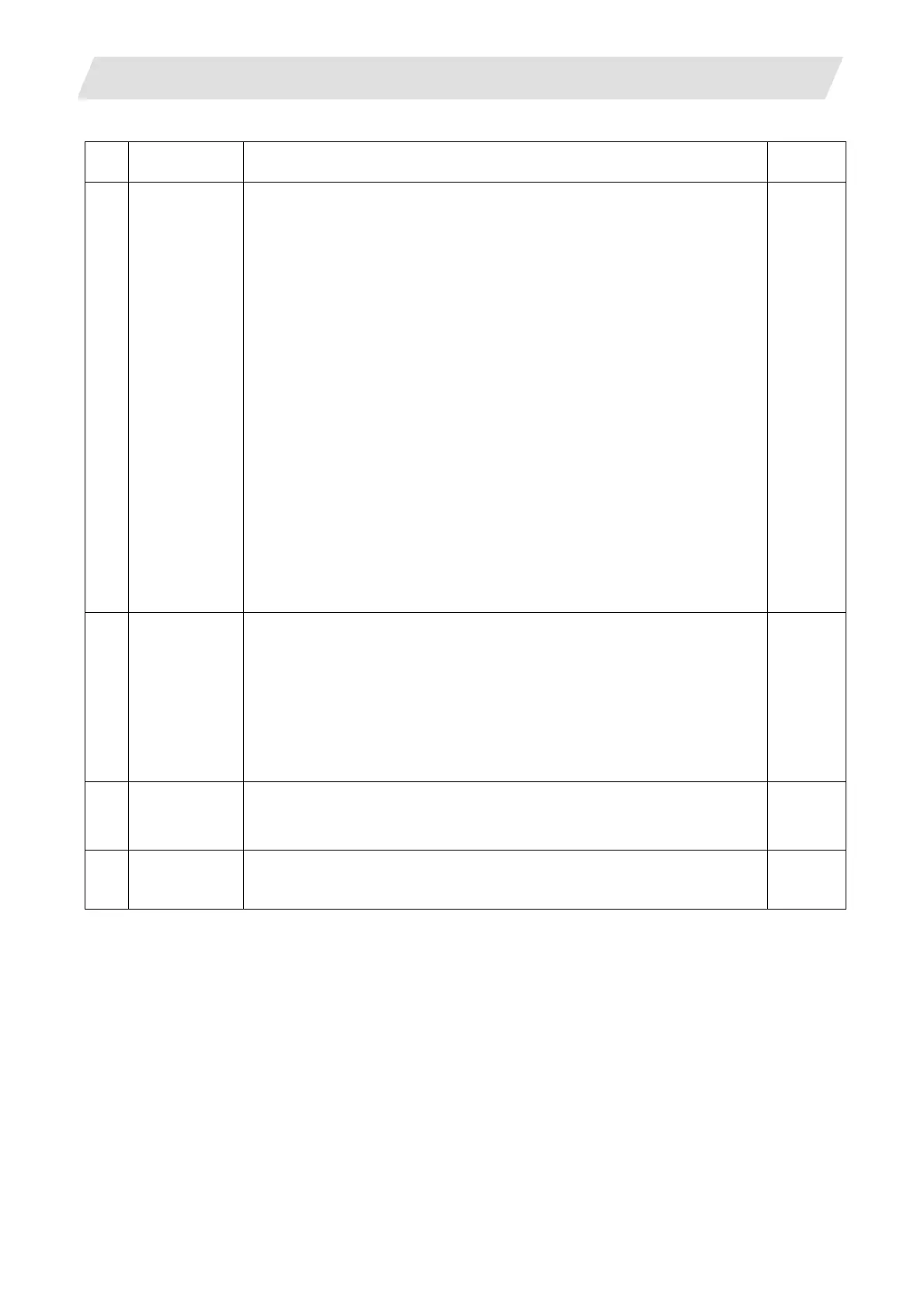

# Item Details

Setting

range

5 S-CONDITION

Select the condition to start sampling.

0: Manual start

Sampling starts when "#0 SMP START" is set to "1".

1: Variable No.

Sampling starts when "#33 VARIABLE No." is set to a non-"0" (nor null)

value in a machining program.

2: PLC device start

Sampling starts when the signal set in "#34 PLC DEVICE" turns ON.

(Note) When "1" is set

• Not the variable value itself but "setting a non-"0" (nor null) value for

the variable in a program" works as a trigger. Therefore, setting a

variable value on COMMON VARIABLE screen or with the PLC

window does not work as a start trigger.

• "Setting the variable to non-0 (nor null) value in a program" is canceled

(the start trigger is turned OFF) by turning ON the reset

(RST1/RST2/RRW) or SA signal.

• If a calculation is used for setting a common variable, which is a

floating point data, the result "0" may not be recognized due to the

calculation error.

• In multi-part system, a start trigger will be turned ON when any one of

the part systems meet the conditions.

0 to 4

6

OUTPUT

FORM

Select the data format when outputting the sampled data in text style.

0: Outputs in decimal figure (64 bits, with sign).

1: Outputs in hexadecimal (32 bits, in 8 digits).

(Note 1) When "1" is set, lower 32 bits of the 64-bit sampled data are

output.

(Note 2) Refer to "2.7.9.4 Data Output Format" for the details of the output

format of sampled data.

0,1

11

to

18

ADR1 to

ADR8

Set the addresses for sampling.

(Note) Refer to "2.7.9.3 Address Designation" for details of the setting

range.

(Note)

21

to

28

UNIT1 to

UNIT8

Not used. Set to "0" (blank).

-

Loading...

Loading...