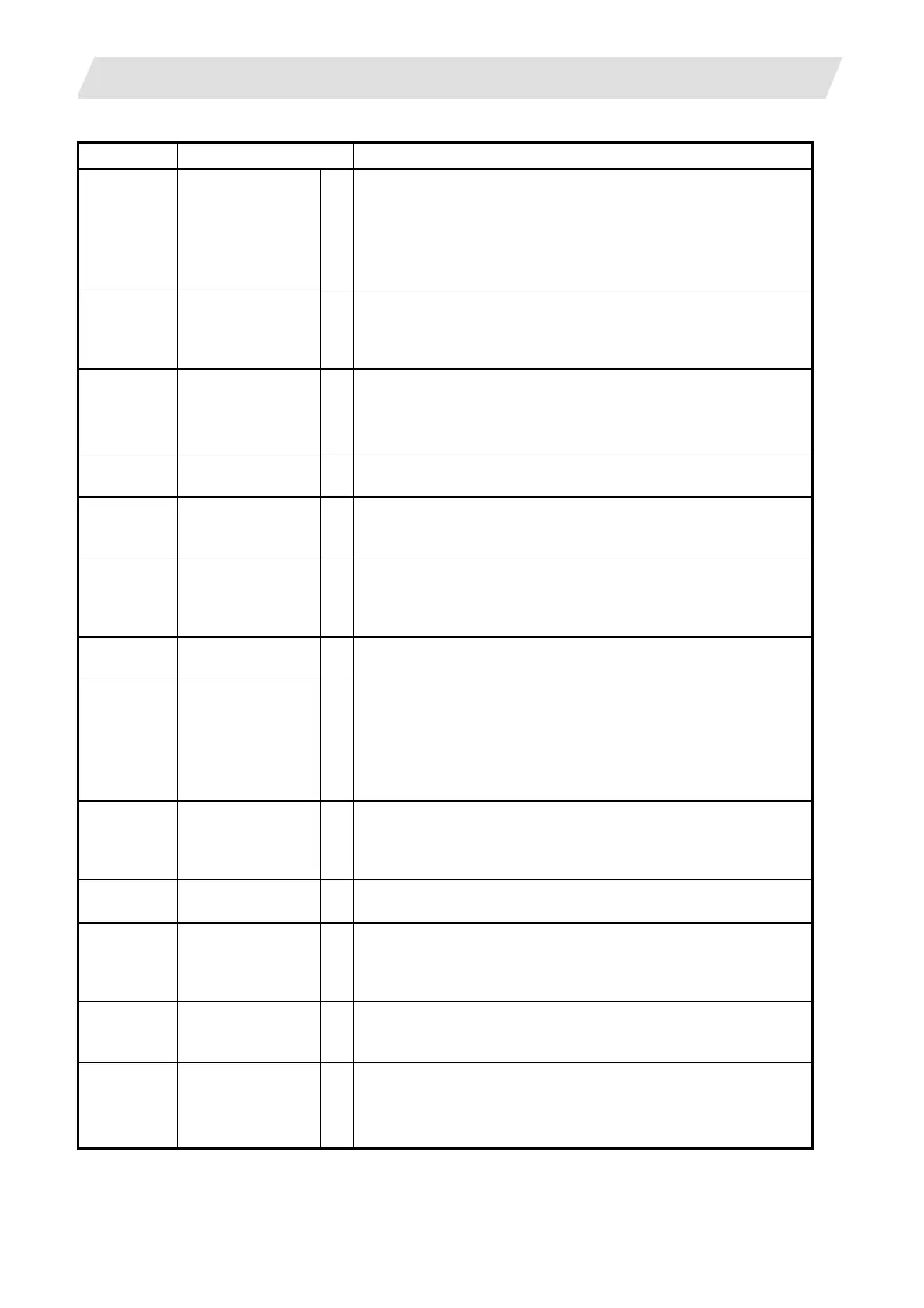

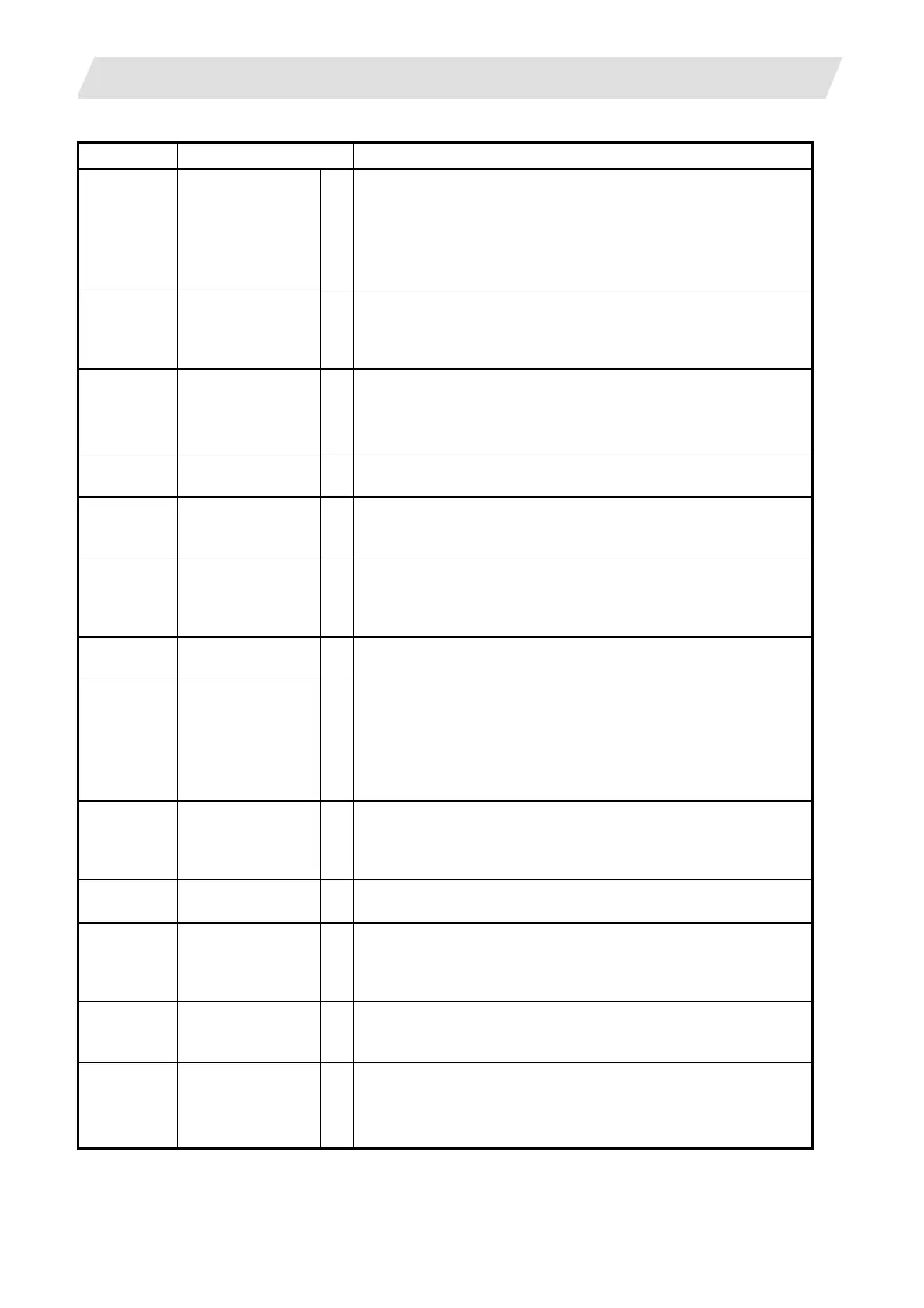

Appendix 6. Operation Messages on Setting Display Unit

Appendix 6.1 Operation Errors

IV - 27

Error No. Error message Details

E60

IOP ERR

×

• Setting for the bit length is incorrect. (Baud rate, stop bit, and

character length)

Check the setting of the I/O device system and its parameters

and set it again.

• Check the situations of the connected devices (cable wiring

and noise measures).

E62 I/O PARAM ERR

Δ

• The “EIA code” data set for I/O parameter is of an unusable

code.

The unusable codes are those used as the EIA standard codes

and the even hole codes.

E64 PROGRAM No.

ERR

Δ

• The same No. as the program No. designated for program

copy was found in the memory.

• During tape input‚ the first character of the machining program

block is the program No. address "O" or "L".

E65 PROG. No. DUPLl

Δ

• During tape input‚ the same No. as the specified program was

found in the memory.

E66 NO PROG.

NUMBER

Δ

• During tape input‚ the program No. was not found on the paper

tape‚ and a program No. was not designated on the screen’s

data setting area. Set the program No.‚ and input again.

E69 PROG. CHECK

MODE

×

• Search (operation search) was attempted during program

check (continuous or step).

Retry search after the program check is completed‚ or after

resetting the program search

E70 TOOL No. DUPLl

Δ

• A tool No. already registered was newly registered on the tool

life management screen.

E71 TOOL ENTRY

OVER

×

• Registration of data exceeding the max. No. of registerable

tools was attempted on the tool life management screen.

• When inputting the tool offset data onto tape‚ a compensation

number exceeding the specifications range was specified‚ and

that block could not be input. If the input key is pressed again

in the input screen‚ the input will continue from the next block.

E76 TOOL No. ERROR

×

• The offset No. to be used for workpiece coordinate system

offset data measurement was invalid. Restart from tool

selection. (Correctly specify the R register that contains the

offset number.)

E77 AXIS NO

REF-RET

×

• Zero point return has not been completed for the axis being

measured. Return the axis to the zero point.

E78 AX UNMATCH

(TLM )

×

• During movement of two or more axes‚ the sensor turned on

and the tool length was measured.

Keep off from the sensor and perform the measurement for

one axis at a time.

E79 NO REF-RTN

(TLM)

×

• The sensor turned on for an axis that has not completed dog-

type reference point return‚ and the tool length was measured.

Return the axis to measure to the reference point.

E84 CAN’T IN/OUT

×

• Parameters were input in the setup parameter lock state.

Refer to the instruction manual issued by the machine maker.

• When using the high-speed program server function, the

parameter "#1925 EtherNet" parameter was set to "0".

Loading...

Loading...