2. CNC Monitor Screen

2.2 Monitor

I - 23

(Note 1) If the type is BCD output and a negative number is set, the positive value converted from it will

be output.

(Example) Manual numeric command

Output

M −100

⇒

M 100

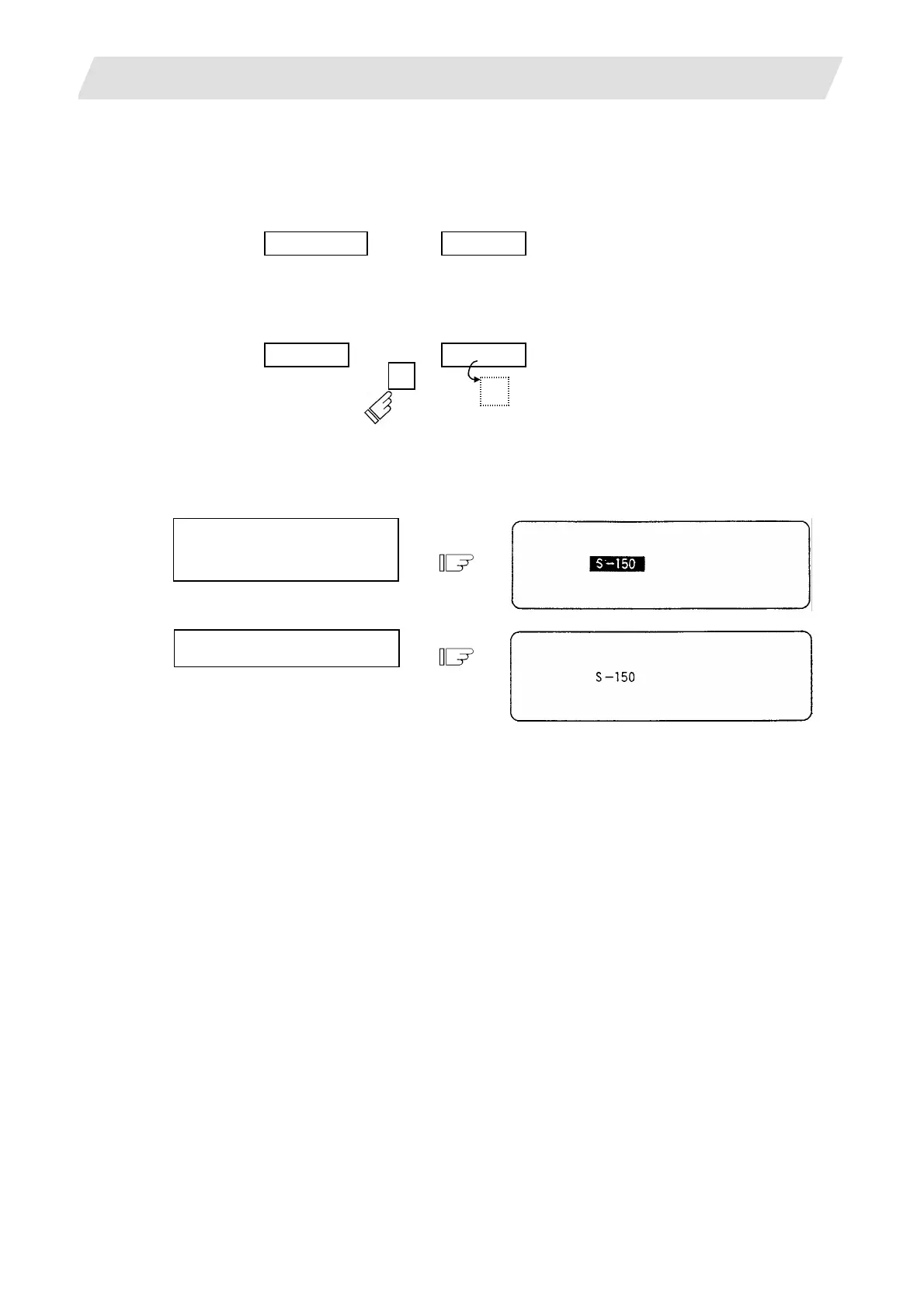

(Note 2) If the number of digits specified in the command exceeds the setting range, the most significant

digit will be lost.

(Example)

M 1234

⇒

M 2345

(5) Other notes on operation

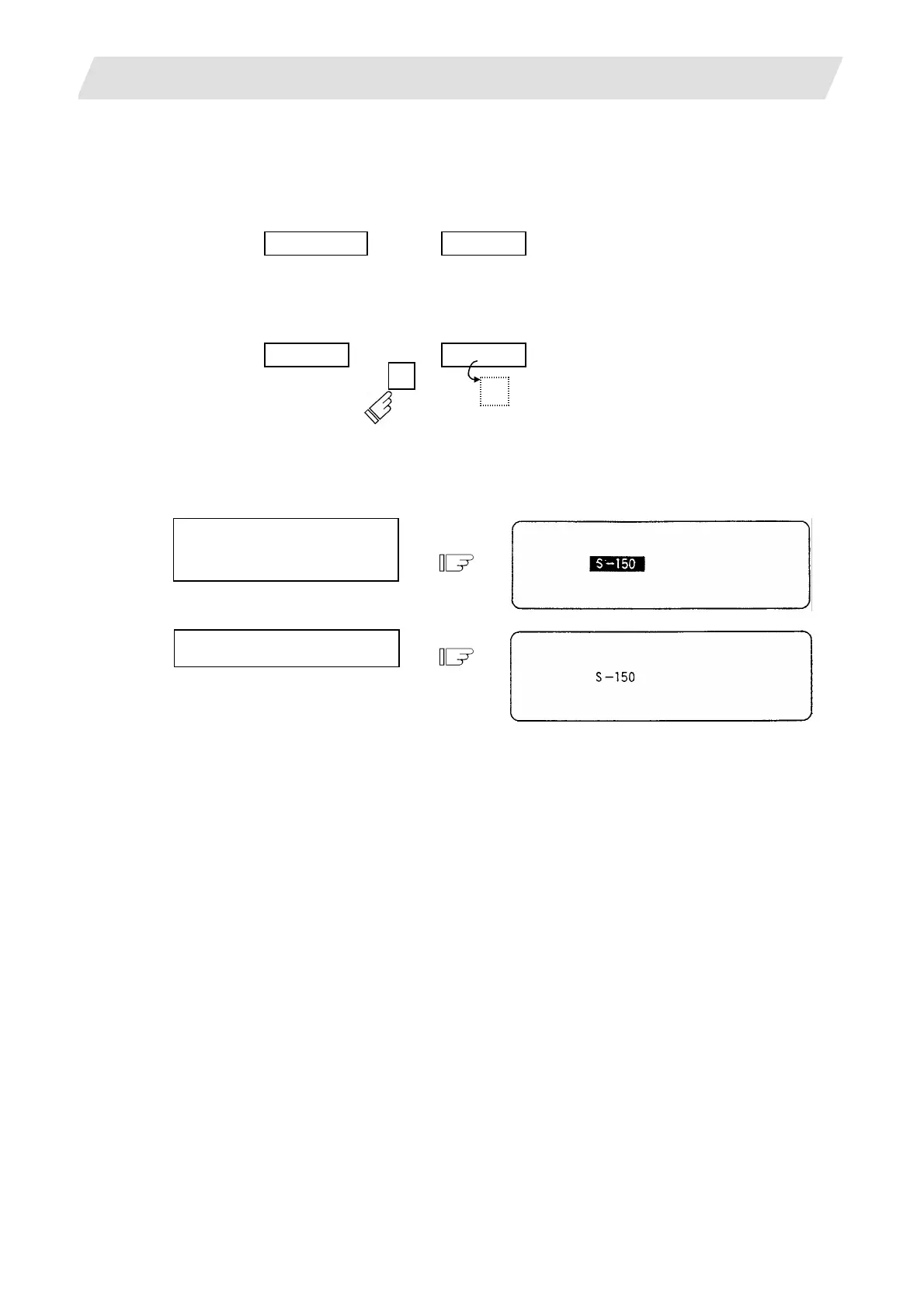

(1) When a minus command is set:

Before setting the numeric, press the [-] (minus) key.

(Example) If S-150 is specified:

Press address key [S] .

Then, press key [-] [1] [5] [0] in

order.

Press [INPUT] key.

(2) When manual numeric command operation stops halfway:

If the operation is desired to be stopped before input after pressing the address key, press any

non-numeric key.

(a) If a manual numeric command address-key such as MST is pressed, the previous operation will

stop. In this case, the next manual numeric command sequentially begins.

(b) If an axis address key (X, Y, or Z, etc.) is pressed, the manual numeric command will stop. In

this case, the origin zero or counter zero mode is then entered.

(c) If the [SHIFT] [C.B CAN] keys are pressed, the manual numeric command will stop. In this case,

the POSITION screen is blanked.

(d) If one of the following keys is pressed, the operation will not stop:

- Position display function key [MONITOR]

- [-]

key pressed before a numeric is set (will be processed as a minus command.)

- [DEL] key when a numeric has been set (The set data will be deleted.)

(3) The macro interruption codes (M96, M97) and subprogram call codes (M98, M99) will not be

processed even if they are issued.

(4) No peripheral-speed command is available.

In the constant peripheral speed mode, no command is processed, if specified.

(5) The set data will be canceled if screen change is executed during manual numeric command

operation.

(6) If operations in which manual numerical commands are carried out (M, S, T keys) are attempted

when the manual numerical command protect function is valid, the error message "E05 SETTING

NOT POSSIBLE" will occur.

5

1 Most significant digit is lost.

Loading...

Loading...