IV - 182

Appendix 8. User Parameters

【#8018】 G84/G74 n (for M system only)

Not used. Set to "0".

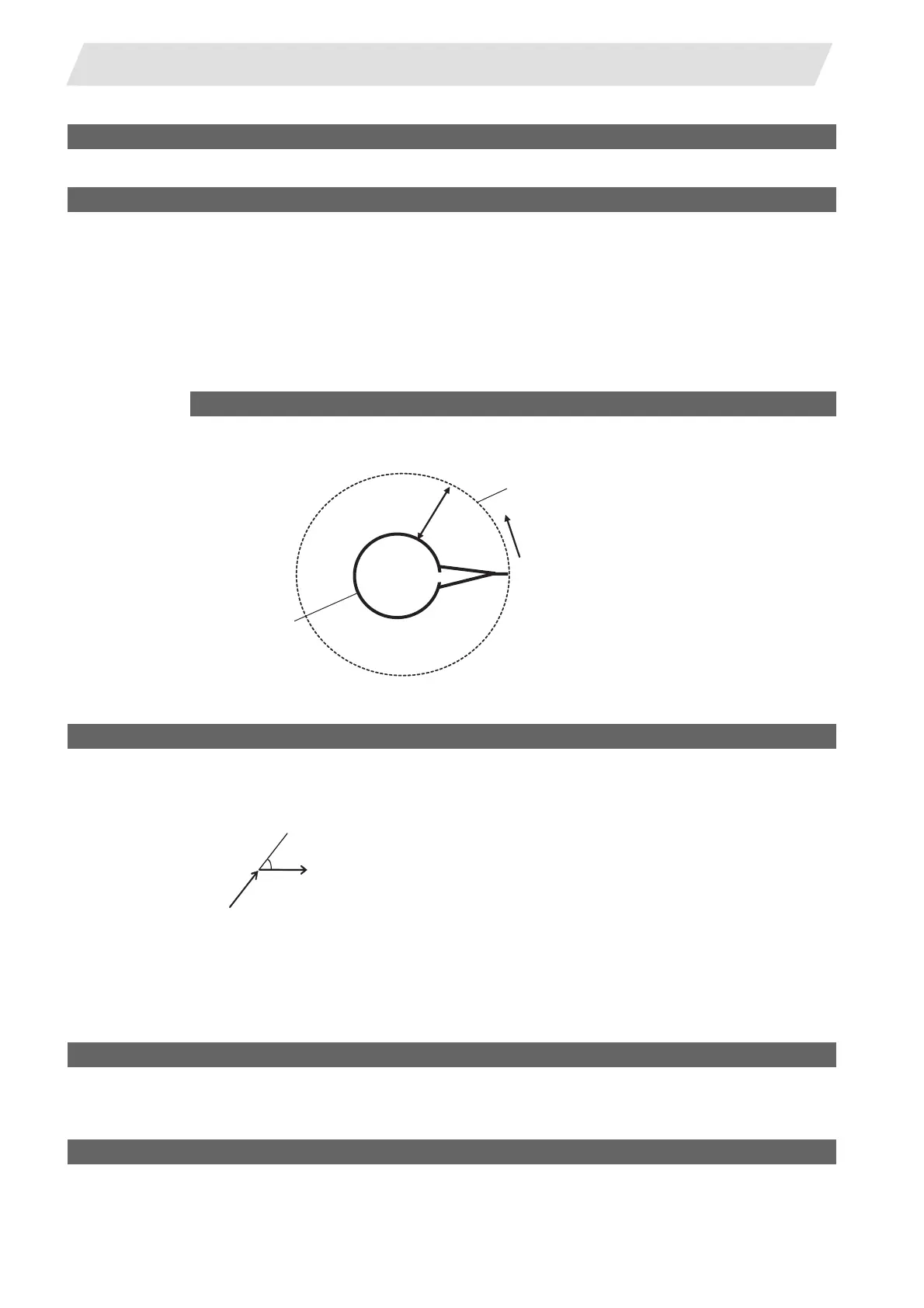

【#8019】 R COMP

Set a compensation coefficient for reducing a control error in the reduction of a corner

roundness and arc radius.

Indicates a maximum control error (mm) in parentheses.

The larger the set value is, the smaller the theoretical error will be. However, since the

speed at the corner goes down, the cycle time will be extended.

Coefficient = 100 - set value

(Note) This function will be enabled when "#8021 COMP_CHANGE" is set to "0".

---Setting range---

0 to 99 (%)

Theoretical radius decrease error amount

Displays the theoretical radius decrease error amount, ΔR(mm), from the automatic

calculation by NC.

Theoretical radius decrease amount in arc

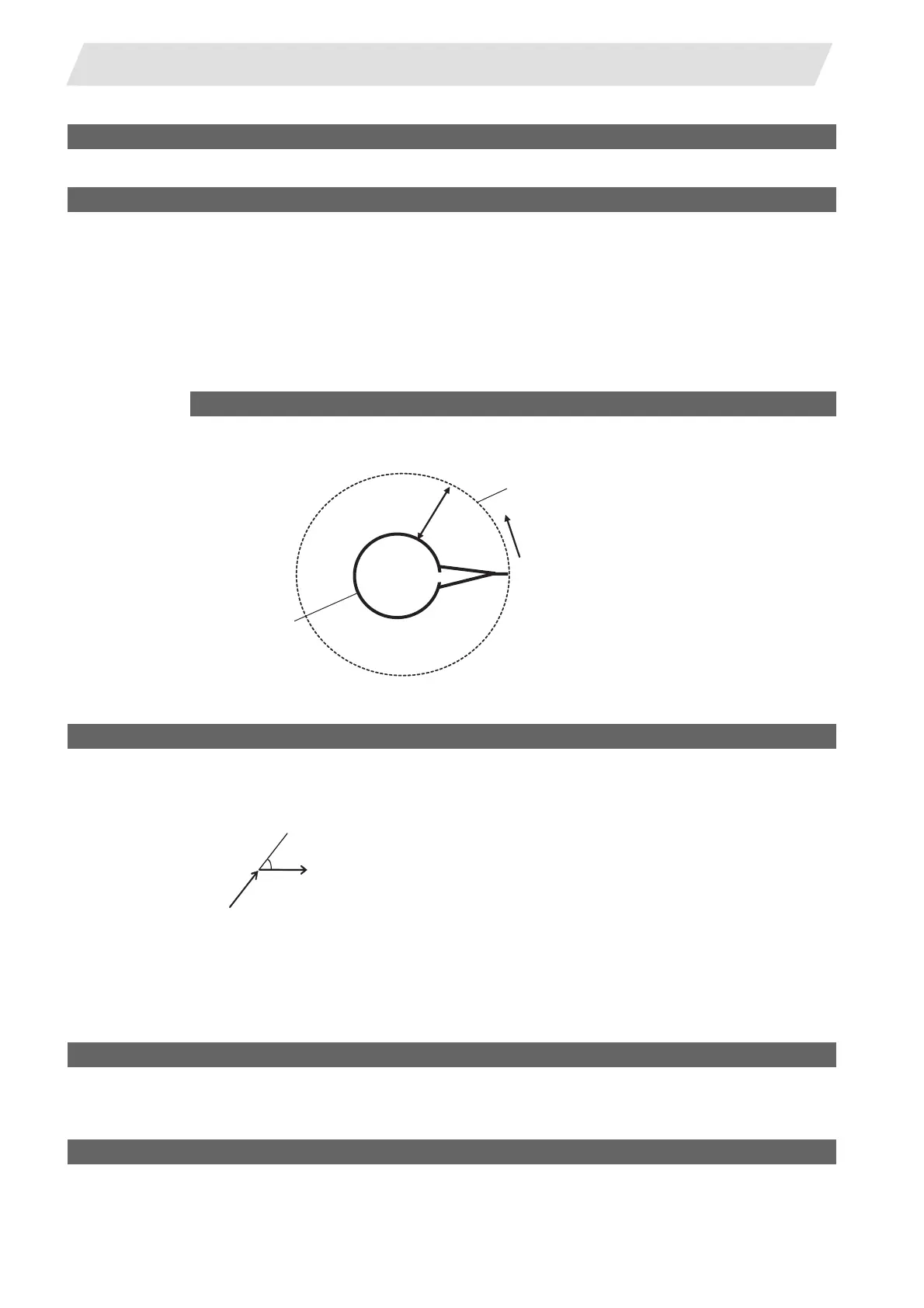

【#8020】 DCC. angle

Set the minimum value of an angle (external angle) that should be assumed to be a

corner.

When an inter-block angle (external angle) in high-accuracy mode is larger than the set

value, it will be determined as a corner and the speed will go down to sharpen the edge.

(Note) If "0" is set, it will be handled as "5" degrees.

The standard setting value is "0".

---Setting range---

0 to 30 (°)

0: 5 degree (Equals to setting "5")

【#8101】 MACRO SINGLE

Select how to control the blocks where the user macro command continues.

0: Do not stop while macro blocks continue.

1: Stop every block during signal block operation.

【#8102】 COLL. ALM OFF

Select the interference (bite) control to the workpiece from the tool diameter during tool

radius compensation and nose R compensation.

0: An alarm will be output and operation stops when an interference is judged.

1: Changes the path to avoid interference.

+

ǍR

F

Command path

Path after

servo control

ǰ

If the set value is smaller than ǰ,

the speed goes down to optimize

the corner.

Loading...

Loading...