2. CNC Monitor Screen

2.3(I) Tool Offset (L system)

(Refer to "2.3 (II). Tool Offset (M system)" for Machining center system)

I - 48

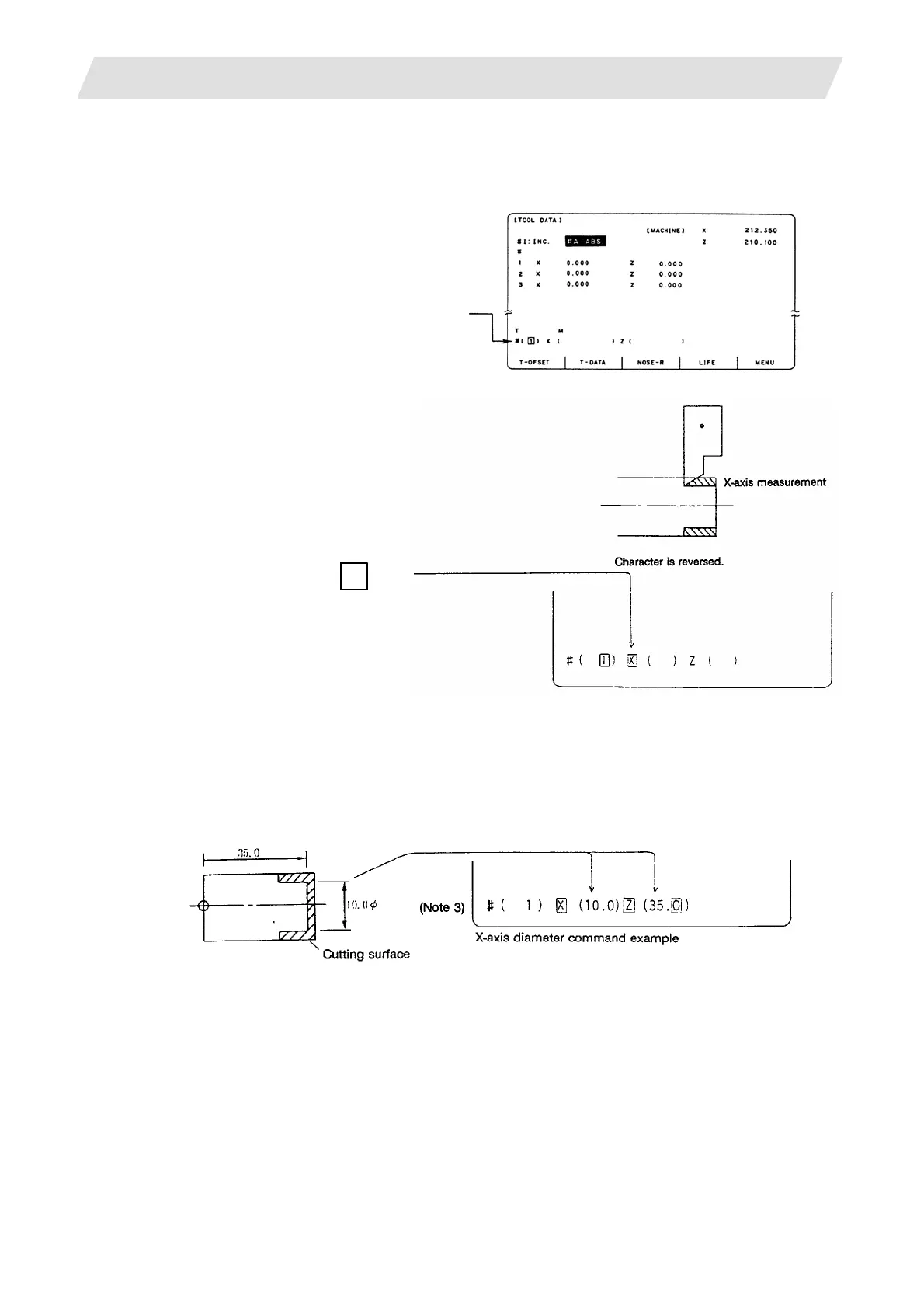

<Measuring procedure for the measuring value input method>

(1) Select the TOOL DATA Screen.

(2) Set the tool No. to be measured in # ( ).

(Select the tool before this step.

It can be selected using a manual

numerical command.)

(Example) Select tool length No."1".

(3) Cut the surface corresponding

to the axis to be measured.

To measure the X axis, cut the

work lengthwise.

(For the Z axis, execute face

turning.)

(4) Do not retract the tool at the

finish point of the cutting, but

press address key of the axis to

be measured.

X axis measurement ...

X

In this way the machine

coordinate values of the

measured axis are stored in the

memory. They are canceled by

pressing the same key twice.

∗Also repeat steps (3) and (4)

for the Z axis.

(5) Retract the tool, and stop the spindle.

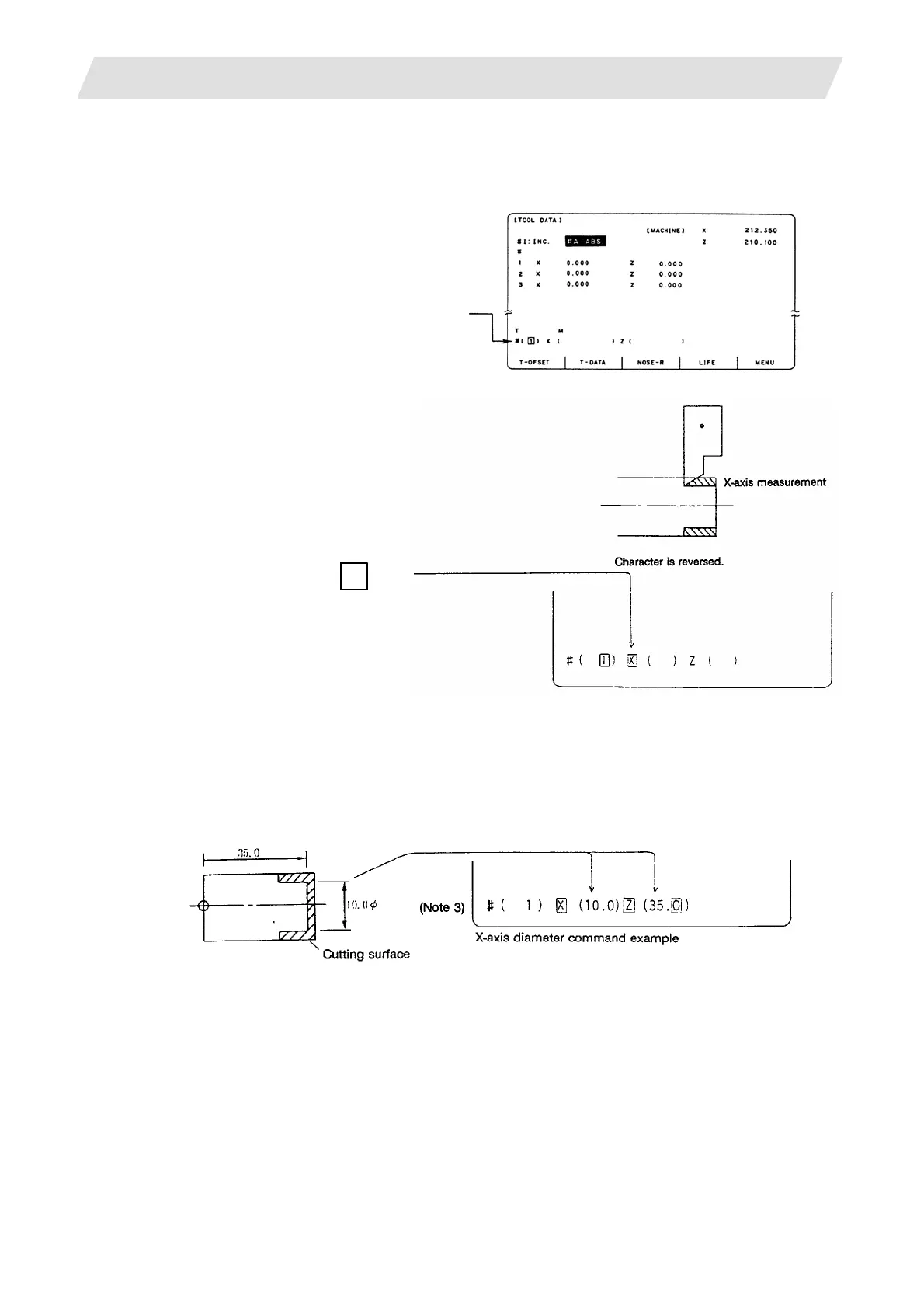

(6) Measure the workpiece, and set the measurement values in the setting areas of each axis. Set the

values for all axes shown in highlighted characters.

(Example)

Base

oint

(Note 1)

(Note 2)

Loading...

Loading...