2. CNC Monitor Screen

2.3(I) Tool Offset (L system)

(Refer to "2.3 (II). Tool Offset (M system)" for Machining center system)

I - 54

(b) Setting the external workpiece coordinate offset data

1) Reference point return

After turning the power ON, establish the coordinate system by carrying out dog-type reference point

return.

When using the absolute position detection specifications, carry out zero point initialization if the

absolute position is not established.

2) Select the mode

Set the mode selection switch to the manual mode (either [handle], [jog] or [rapid traverse]).

3) Input the tool measurement mode signal

Set the tool measurement mode signal to "1".

The tool measurement mode is entered with steps 1), 2) and 3).

4) Select the tool

Issue the T command with MDI operation, etc., and select the tool.

(Note 1) Set the compensation No. of the tool to be selected in the R register (R register

corresponding to the compensation No.).

(Note 2) Preset the tool length data and wear data for the tool to be used.

5) Cut workpiece edges

If the workpiece edges have not been cut, cut them slightly to flatten the workpiece edges.

(Note 1) Do not move the tool in the Z axis direction after cutting the workpiece edges.

(Note 2) If the edges do not need to be cut, position to the measurement position.

6) Set the Z axis external workpiece offset data with the workpiece measurement signal input

Turn ON the workpiece measurement signal. The Z axis external workpiece coordinate offset data will

be automatically calculated from the machine value at the time the signal is turned ON and the tool

compensation data of the tool used. The data will then be set.

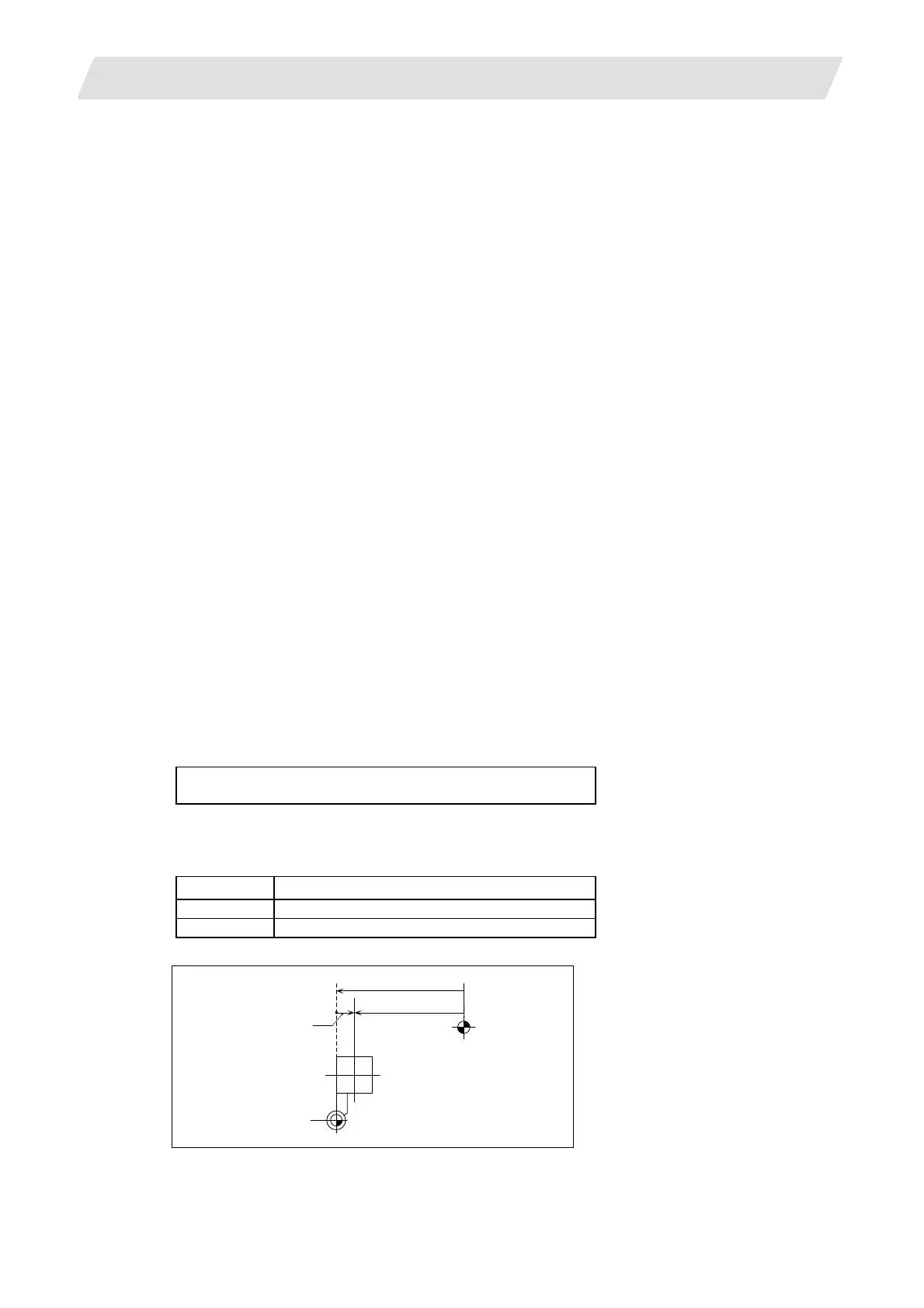

(i) Details of automatic calculation expression

The external workpiece coordinate offset data is automatically calculated with the following

expression.

(Refer to “External workpiece coordinate offset calculation diagram”)

External workpiece coordinate offset

= Machine coordinate value – Tool compensation data

The tool compensation data used for the measurement is selected with the base specification

parameter "#1226 aux10 bit0".

aux10 bit0 Tool compensation data

0 Tool length data + nose wear data

1 Tool length data

External workpiece coordinate offset

Tool compensation

amount

Basic machine

coordinate

zero point

Workpiece coordinate

system zero point

Machine value

Tool post

system

External workpiece coordinate offset calculation diagram

Loading...

Loading...