2. CNC Monitor Screen

2.3(I) Tool Offset (L system)

(Refer to "2.3 (II). Tool Offset (M system)" for Machining center system)

I - 55

(ii) Selected tool's compensation No.

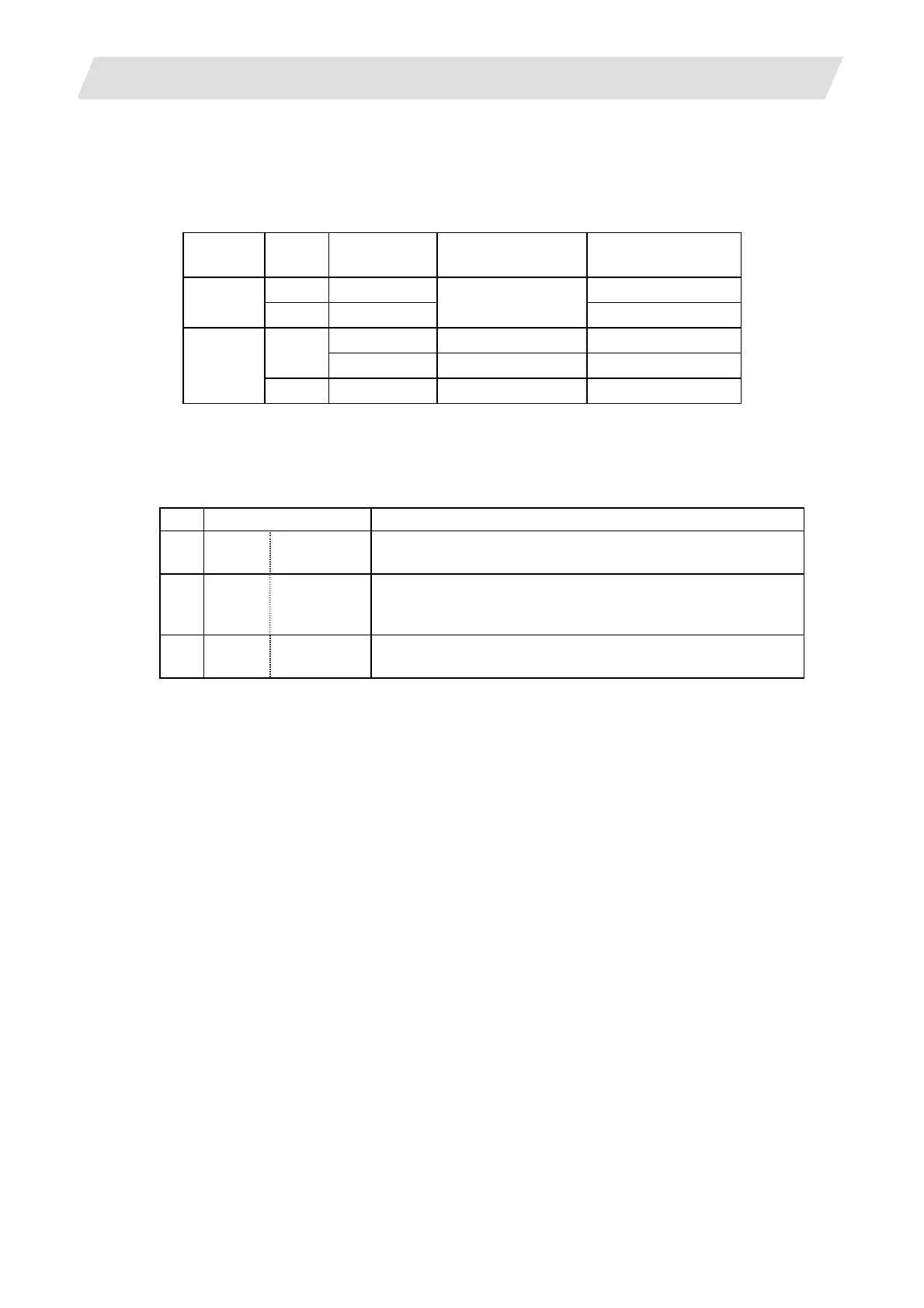

The number set in the R registers, shown in the table below, are used as the tool length and nose

wear data compensation numbers for automatic calculation.

Compensation No. R registers

#1098

Tlno.

#1130

set_t

#1218 aux02

bit4

Tool length

compensation No.

Nose wear

compensation No.

0 0/1 R2446, R2447

0

1 0/1

R2446, R2447

0 R120, R121 R2446, R2447

0

1 R2448, R2449 R2446, R2447

1

1 0/1 R2448, R2449 R2446, R2447

(Note 1) If the compensation No. is 0, the compensation amount will be calculated as "0".

(Note 2) If the compensation No. exceeds the number of offset sets in the specifications, the "E76

TOOL No. ERROR" error will occur.

(Note 3) The details of the parameters are shown below.

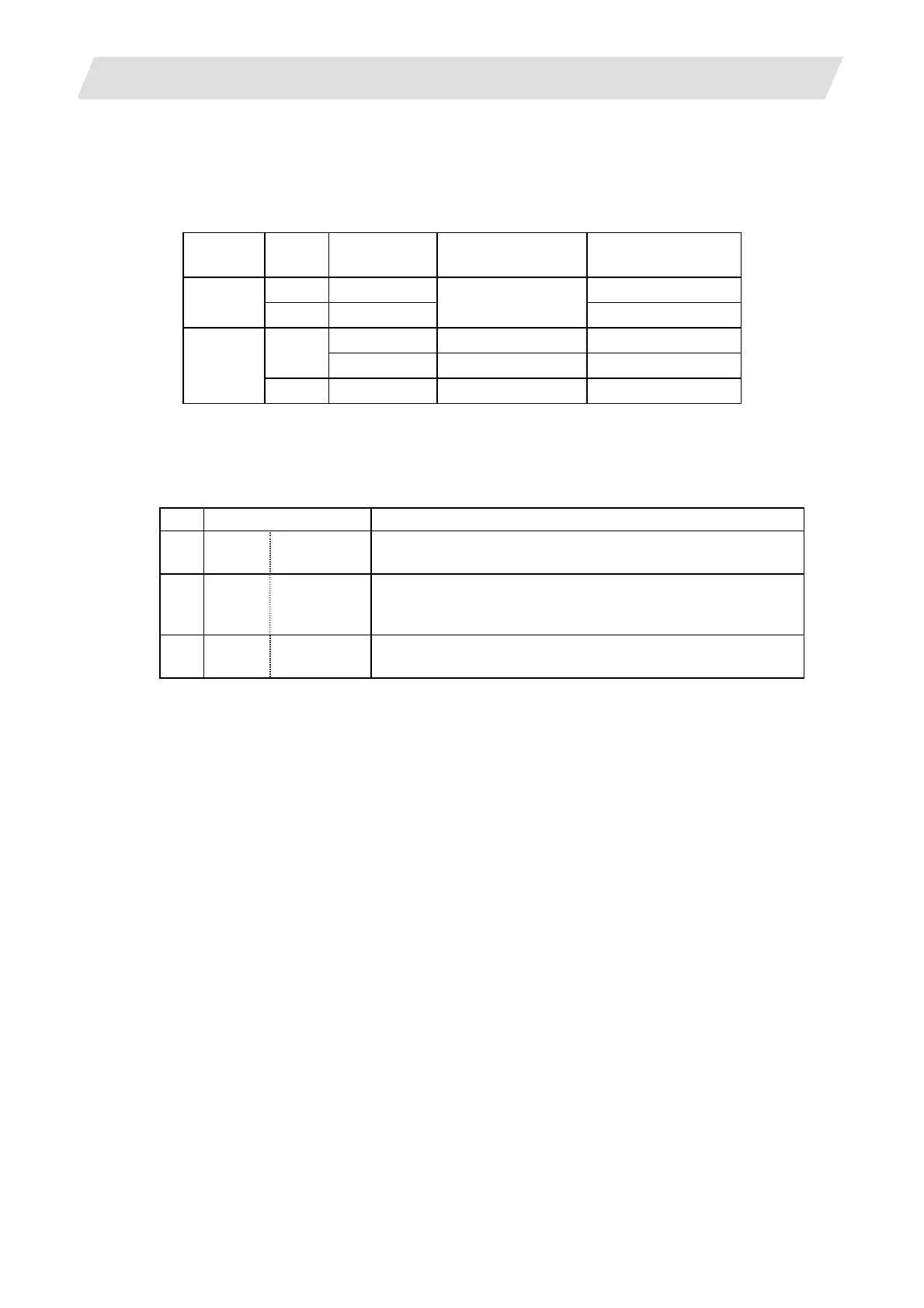

# Items Details

1098 Tlno.

Tool length

offset number

0: Tool length offset No. = Nose wear compensation No.

1: Tool length offset No. = Tool No.

1130 set_t

Display

selected tool

number

0: NC command

1: Command by user PLC

1218

aux02

(bit4)

Tool number

selection

0: Conforms to "#1130 set_t".

1: Uses the tool number commanded by user PLC

7) Turn the tool measurement mode signal OFF.

This completes the measurement of the external workpiece coordinate offset.

When carrying out this operation independently, follow steps 1) to 7), and when carrying out after

measuring the tool compensation amount, carry out steps 4) to 6) between 9) and 10) of “(a) Setting

the tool compensation amount”.

(4) Precautions

1) When entering the sensor area, the axis can move only in one direction selected from +X, –X, +Z, –Z,

(+Y, –Y).

If two axes (ex. +X, –Z) are moved simultaneously, it will not be clear which contact surface was

contacted, so the measurement will not be made. Note that the error "E78 AX UNMATCH (TLM )" will

occur and the movement will stop for safety purposes.

2) After entering the sensor area, if the nose is contacting the sensor, the axis can be moved only in the

direction away from the sensor. (An interlock is applied on the entry direction by the NC.)

The axis can move in both directions when the nose is separated from the sensor.

Loading...

Loading...