Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Building

Automation

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

HVAC Drive H300 129

Issue Number: 3

6.3.3 Status information

The parameter displays the software version of the drive

6.3.4 Speed limits

Open-loop

Set Pr 00.010 at the required minimum output frequency of the drive for

both directions of rotation. The drive speed reference is scaled between

Pr 00.010 and Pr 00.011. [00.010] is a nominal value; slip compensation

may cause the actual frequency to be higher.

RFC-A / RFC-S

Set Pr 00.010 at the required minimum motor speed for both directions

of rotation. The drive speed reference is scaled between Pr 00.010 and

Pr 00.011.

(The drive has additional over-speed protection).

Open-loop

Set Pr 00.011 at the required maximum output frequency for both

directions of rotation. The drive speed reference is scaled between

Pr 00.010 and Pr 00.010. [00.011] is a nominal value; slip compensation

may cause the actual frequency to be higher.

RFC-A / RFC-S

Set Pr 00.011 at the required maximum motor speed for both directions

of rotation. The drive speed reference is scaled between Pr 00.010 and

Pr 00.011.

For operating at high speeds see section 8.4 High speed operation on

page 162.

6.3.5 Ramps

Set Pr 00.012 to the required rate of acceleration.

Note that larger values produce lower acceleration. The rate applies in

both directions of rotation.

Set Pr 00.013 to the required rate of deceleration.

Note that larger values produce lower deceleration. The rate applies in

both directions of rotation.

6.3.6 Voltage boost, (open-loop), Speed-loop PID

gains (RFC-A / RFC-S)

Open-loop

There are seven voltage modes available, which fall into three

categories, vector control, fixed boost and single phase current output.

For further details, refer to section 8.1.1 Open loop motor control on

page 151.

RFC-A/ RFC-S

Pr 00.014 (03.010) operates in the feed-forward path of the speed-

control loop in the drive. See Figure 11-4 Menu 3 RFC-A, RFC-S logic

diagram on page 214 for a schematic of the speed controller. For

information on setting up the speed controller gains, refer to section

8 Optimization on page 151.

Open-loop

Set Pr 00.015 (05.013) at 0 when the V/f characteristic applied to the

motor is to be fixed. It is then based on the rated voltage and frequency

of the motor.

Set Pr 00.015 at 1 when reduced power dissipation is required in the

motor when it is lightly loaded. The V/f characteristic is then variable

resulting in the motor voltage being proportionally reduced for lower

motor currents. Figure shows the change in V/f slope when the motor

current is reduced.

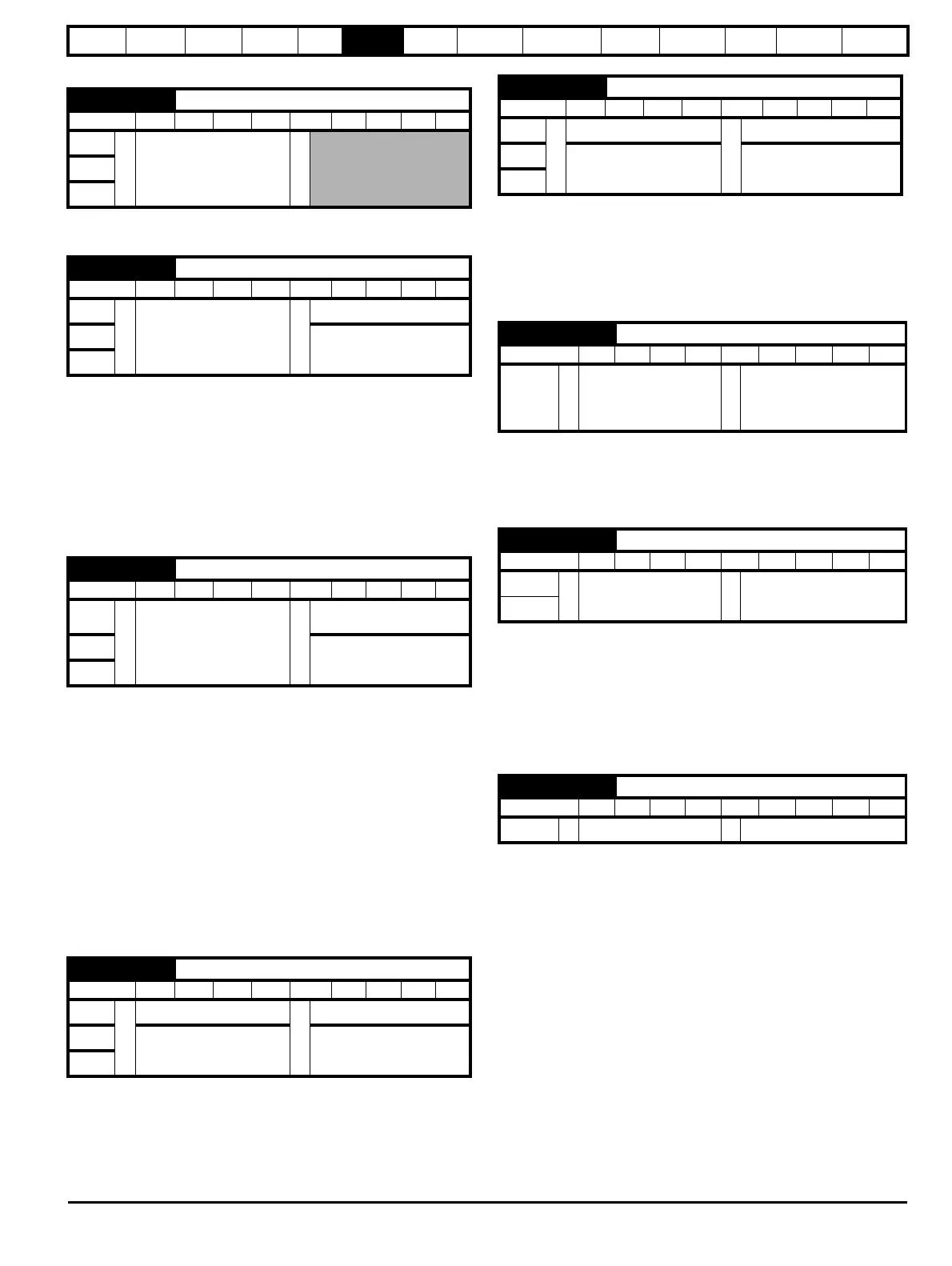

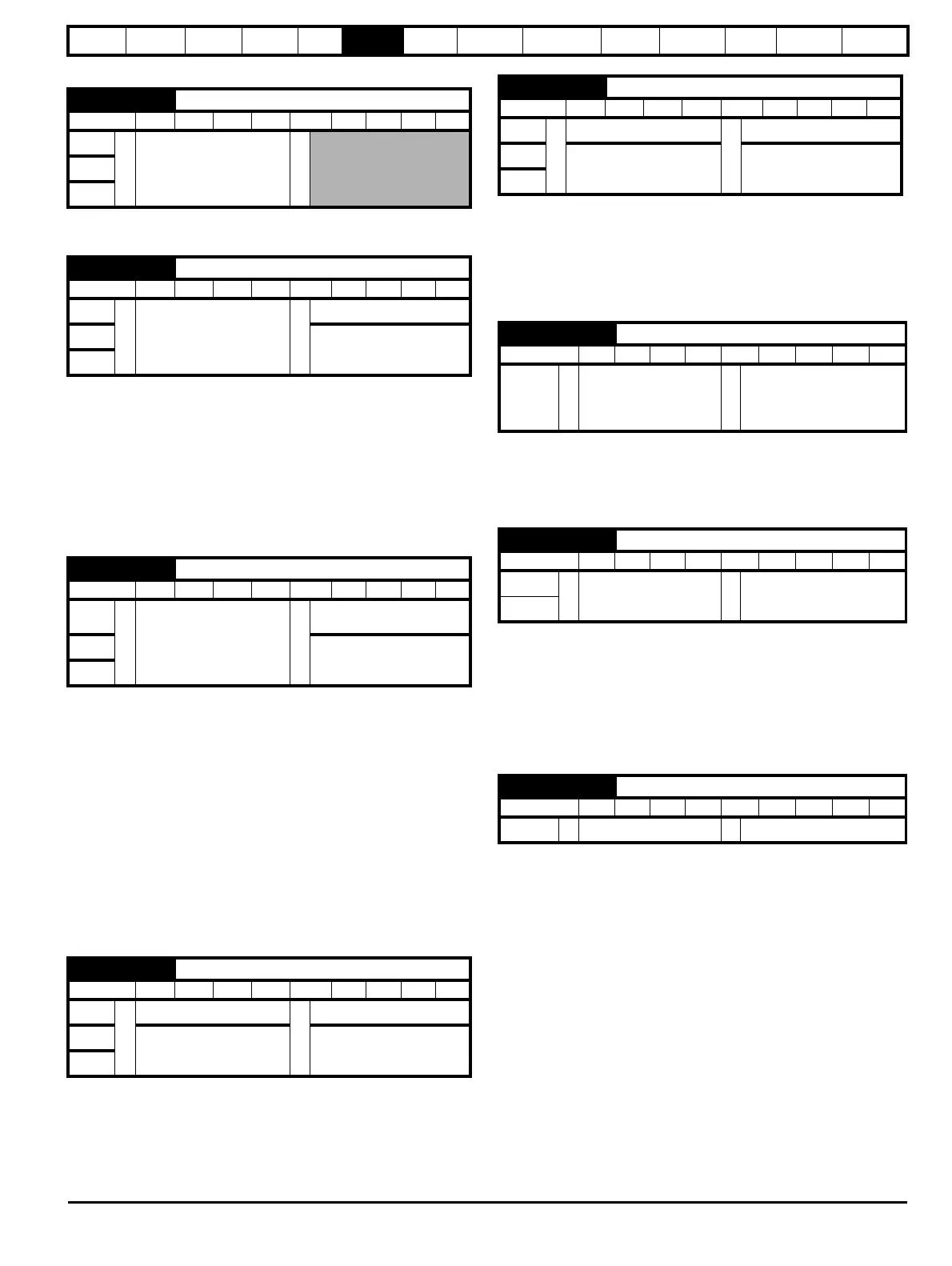

00.005 {11.029} Software Version

RO Num ND NC PT

OL

Ú

0 to 99999999

Ö

RFC-A

RFC-S

00.010 {01.007} Minimum Reference Clamp

RW Num US

OL

Ú

VM_NEGATIVE_REF_

CLAMP1 Hz / rpm

Ö

0.0 Hz

RFC-A

0.0 rpm

RFC-S

00.011 {01.006} Maximum Reference Clamp 1

RW Num US

OL

Ú

VM_POSITIVE_REF_

CLAMP1 Hz / rpm

Ö

50Hz default: 50.0 Hz

60Hz default: 60.0 Hz

RFC-A

50Hz default:1500.0 rpm

60Hz default:1800.0 rpm

RFC-S

00.012 {02.011} Acceleration Rate 1

RW Num US

OL

Ú

0.0 to VM_ACCEL_RATE

Ö

20.0 s to Pr 01.006

RFC-A

0.000 to

VM_ACCEL_RATE

20.000 s to Pr 01.006

RFC-S

00.013 {02.021} Deceleration Rate 1

RW Num US

OL

Ú

0.0 to VM_ACCEL_RATE

Ö

20.0 s from Pr 01.006

RFC-A

0.000 to

VM_ACCEL_RATE

20.000 s from Pr 01.006

RFC-S

00.014 {05.014} Open-loop Control Mode

RW Txt US

OL

Ú

Ur S (0), Ur (1),

Fixed (2), Ur Auto (3),

Ur I (4), Square (5),

Current 1P (6)

Ö

Ur I (4)

00.014 {03.010} Speed Controller Proportional Gain Kp1

RW Num US

RFC-A

Ú

0.0000 to 200.000 s/rad

Ö

0.0300 s/rad

RFC-S

00.015 {05.013} Dynamic V to F Select

RW Bit US

OL

Ú

Off (0) or On (1)

Ö

On (1)

Loading...

Loading...