Description

2-9

Part 1602966−05

E 2015 Nordson Corporation

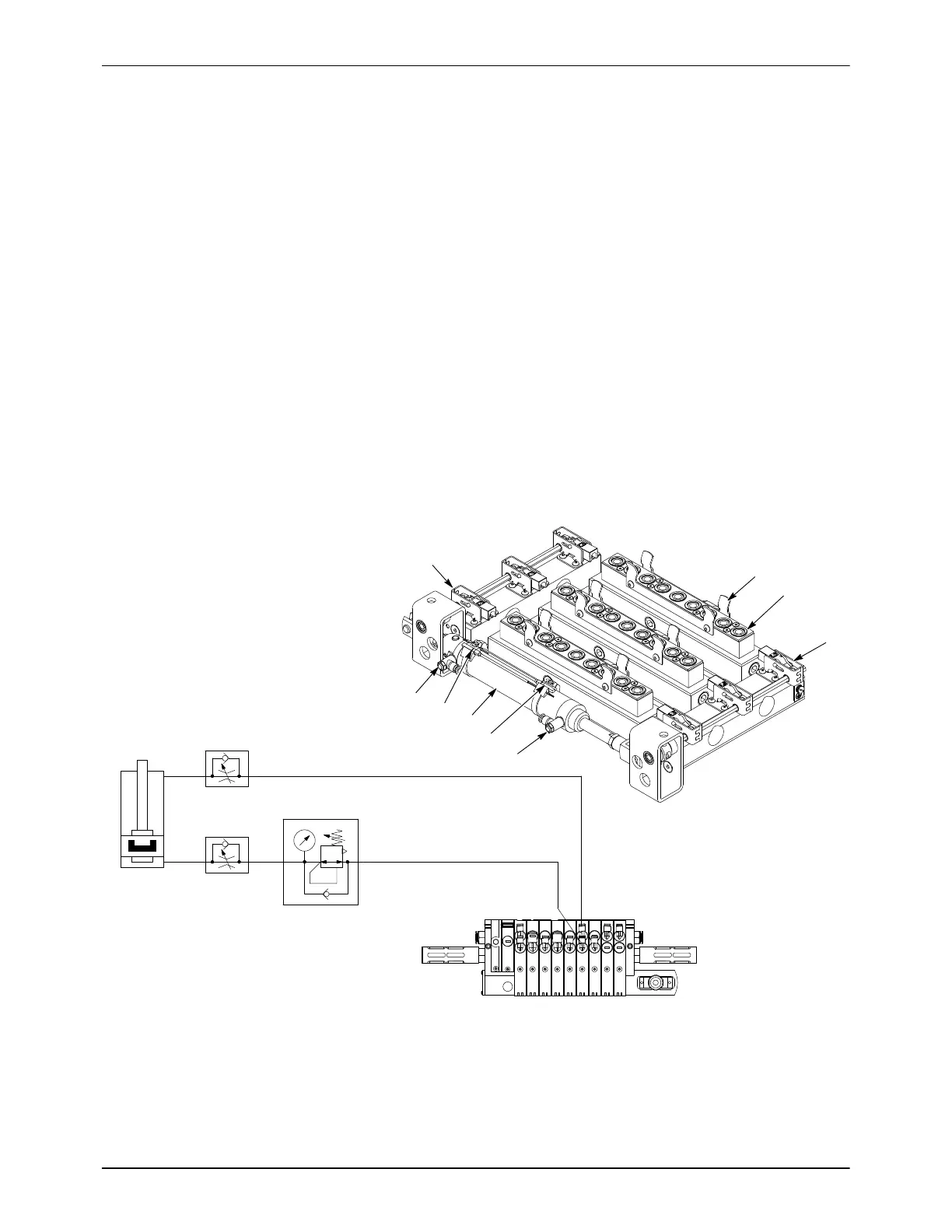

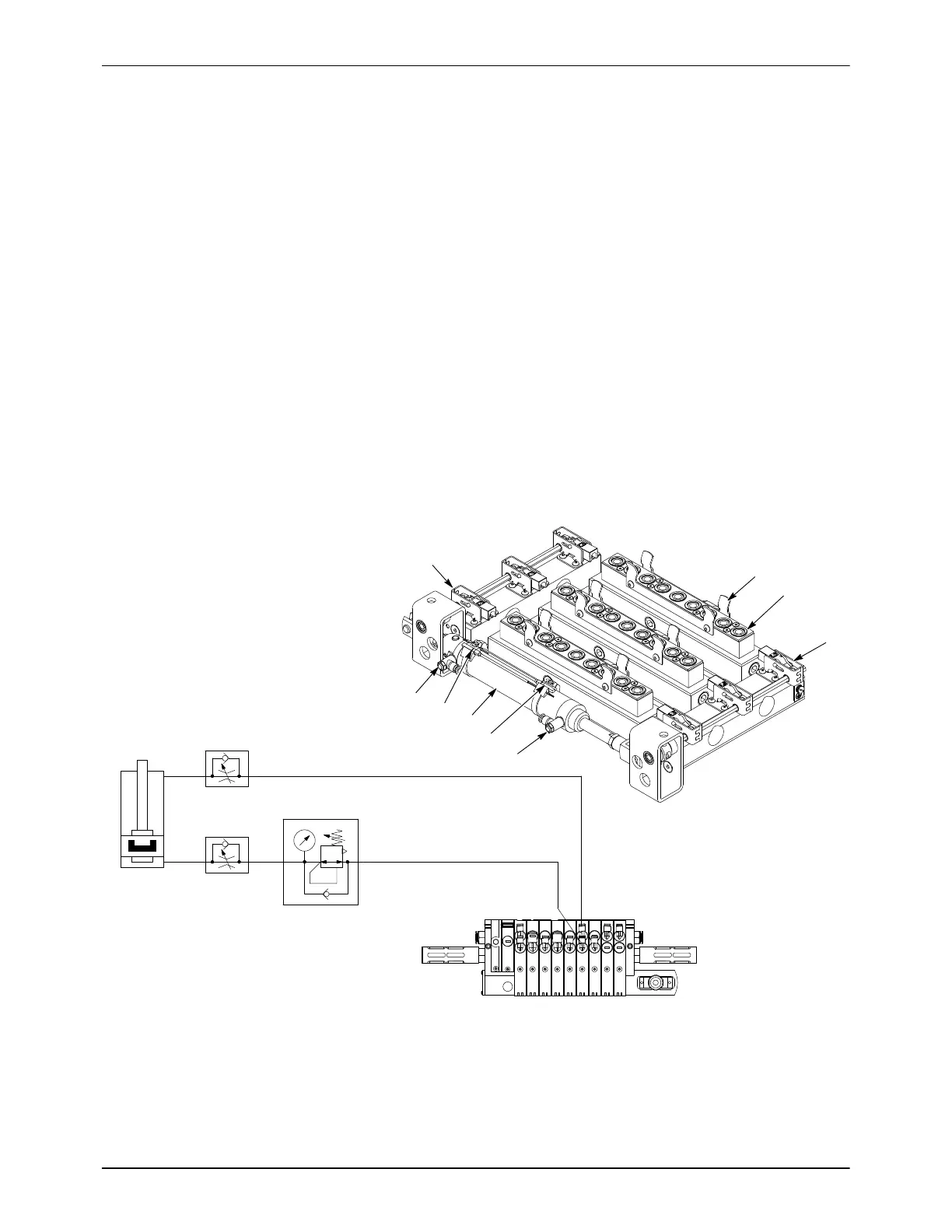

Purge Manifold

When the operator activates the gun purge mode during a color change

procedure, the lance assemblies are lowered onto the purge manifolds (1).

The latch cylinder (4) is extended, causing the latches (3) to clamp the

lances to the purge manifolds. Compressed air is then pulsed through the

lances, in-line pumps, feed hoses, and spray guns, one manifold at a time.

The purge sequence is controlled by the feed center PLC. Air is supplied by

the purge valves mounted on the back of the feed center.

The latch assemblies can be adjusted to change the clamping force exerted

on the lance assemblies, depending on the purge air pressure. Refer to the

Repair section, page 8-4, for adjustment procedures.

Clamping Cylinder Operation

Extend (Clamp): The extend air line is pressurized with regulated air,

forcing the cylinder rod out of the cylinder. The retract air line is vented.

Retract (Unclamp): The retract air line is pressurized with line air pressure,

forcing the cylinder rod into the cylinder. The extend air line is vented.

1

2

3

4

5

5

3

1

2

2

1

1

2

6 mm

6 mm

PURGE CLAMP

CYLINDER

FLOW

CONTROL

FLOW

CONTROL

REGULATOR

EXTEND

RETRACT

NINE-STATION CONTROL MANIFOLD

6

7

1

2345

6789

Figure 2-6 Purge Manifold Assembly (3 lance assembly shown with cylinder and latches in clamping position)

1. Manifold assembly

2. Lance guides

3. Latches

4. Latch cylinder

5. Piston proximity sensors

6. Extend flow control valve

7. Retract flow control valve

Loading...

Loading...