Maintenance

6-2

Part 1602966−05

E 2015 Nordson Corporation

Periodic Maintenance

NOTE: You may need to perform these procedures more or less often,

depending on your application requirements.

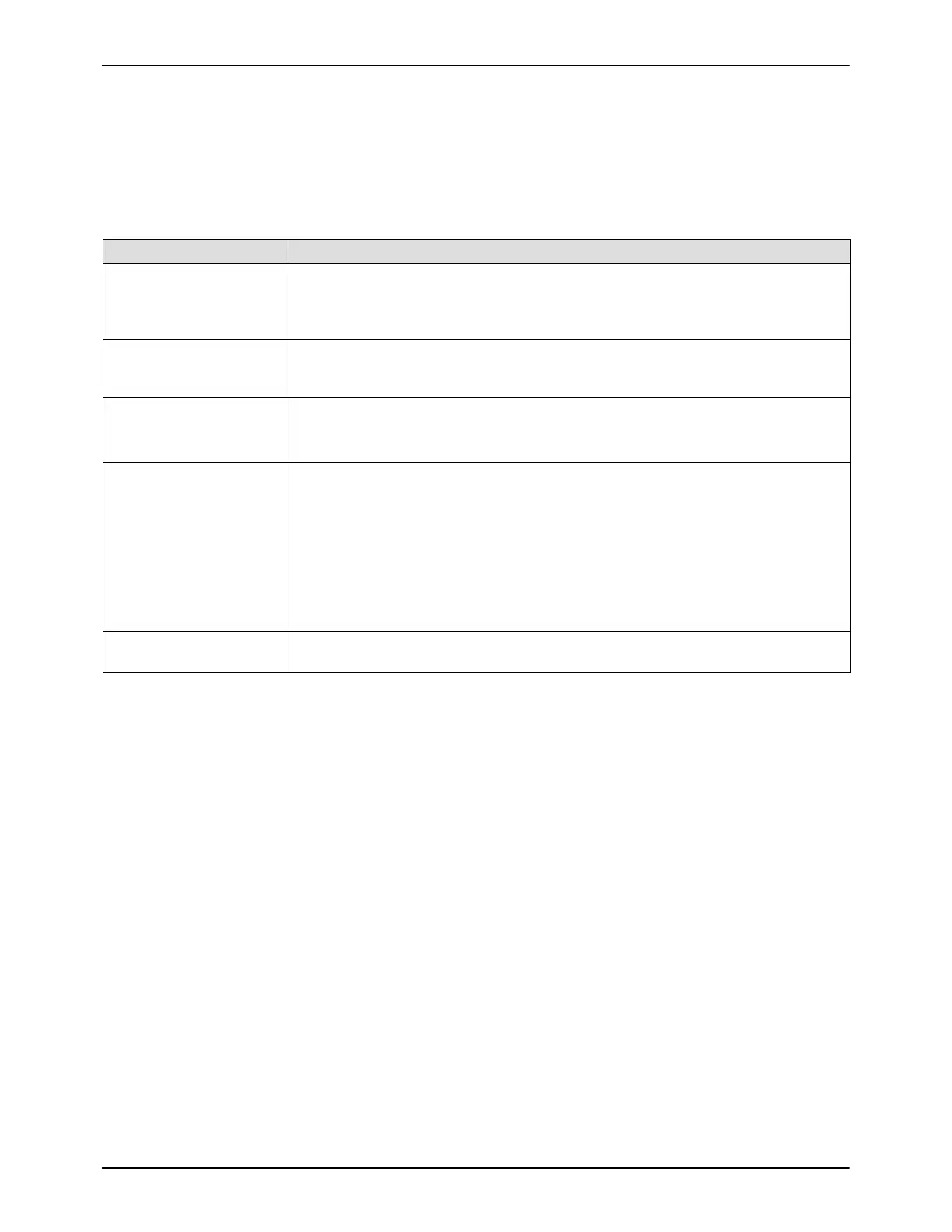

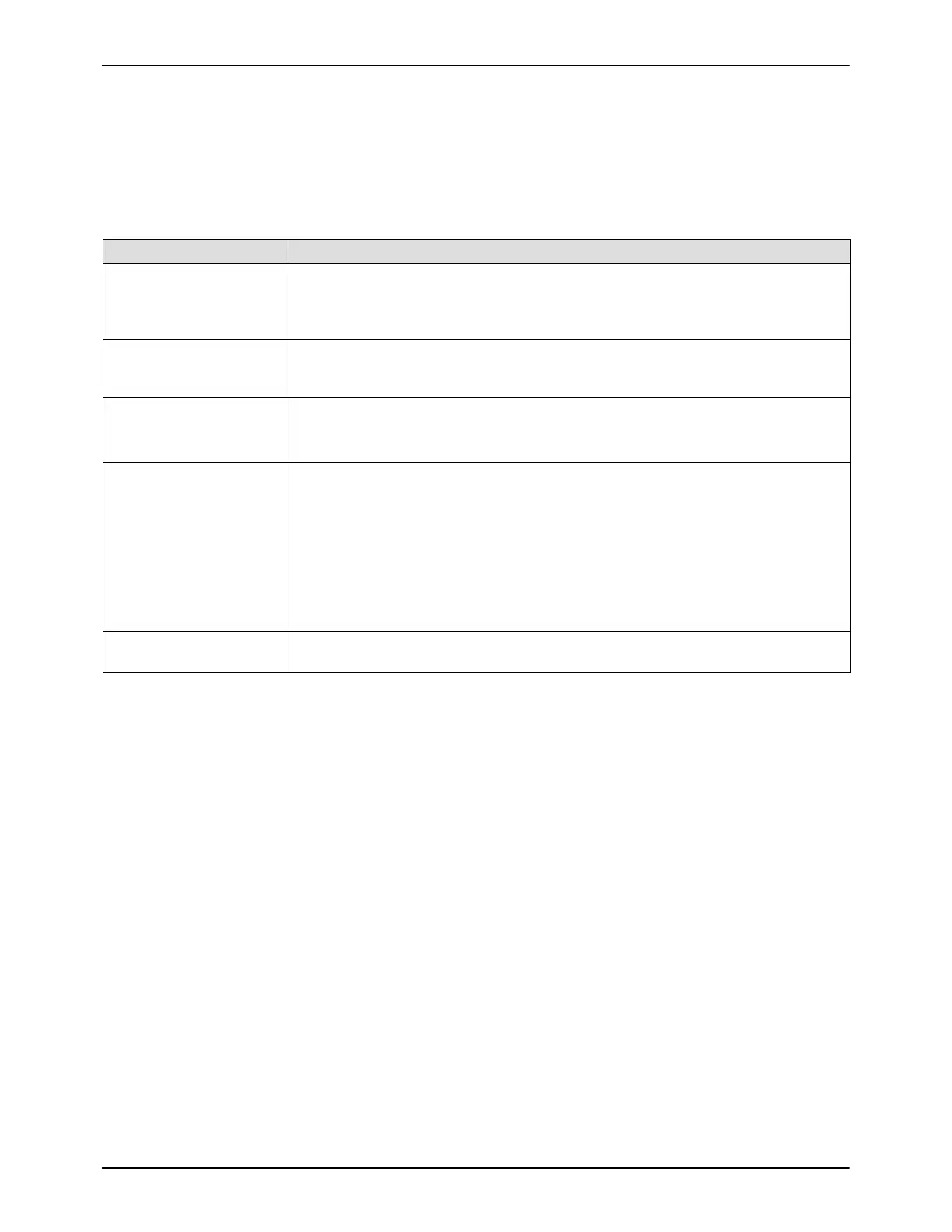

Table 6-2 Periodic Maintenance Procedures

Component Maintenance Procedure

Air Flow Take regular air flow readings at the face of the feed center. A properly

functioning powder feed center should provide a face velocity of approximately

2.8 m

3

/min (100 ft

3

/min). A lower reading indicates clogged ducts or afterfilter

cartridge filters.

Compressed Air

System

Open the drop leg and use a clean, white cloth to check for contaminants.

Correct any problems immediately. Drain the air filters and change the

elements as necessary.

Electrical System Tighten all electrical connections and inspect for loose or broken wires.

Check the electrical system for electrical safety every 12 months. The system

must comply with all local, state, and federal codes.

System Grounds Check all equipment grounds. Electrical equipment must be grounded

according to code. For maximum transfer efficiency and safety, electrostatic

equipment must be grounded to provide a complete circuit from the spray

guns through the workplace hangers, conveyors, and booth back to the gun

controllers.

Refer to Grounding in the Safety section of this manual and to publication

number TCTT-06-3881 on the Nordson emanuals web site

(http://emanuals.nordson.com/finishing) for more information on powder

coating system grounding.

Air Tubing Pressurize the system and listen for air leaks. Replace or repair any leaking

tubing or fittings.

Loading...

Loading...