Description

2-5

Part 1602966−05

E 2015 Nordson Corporation

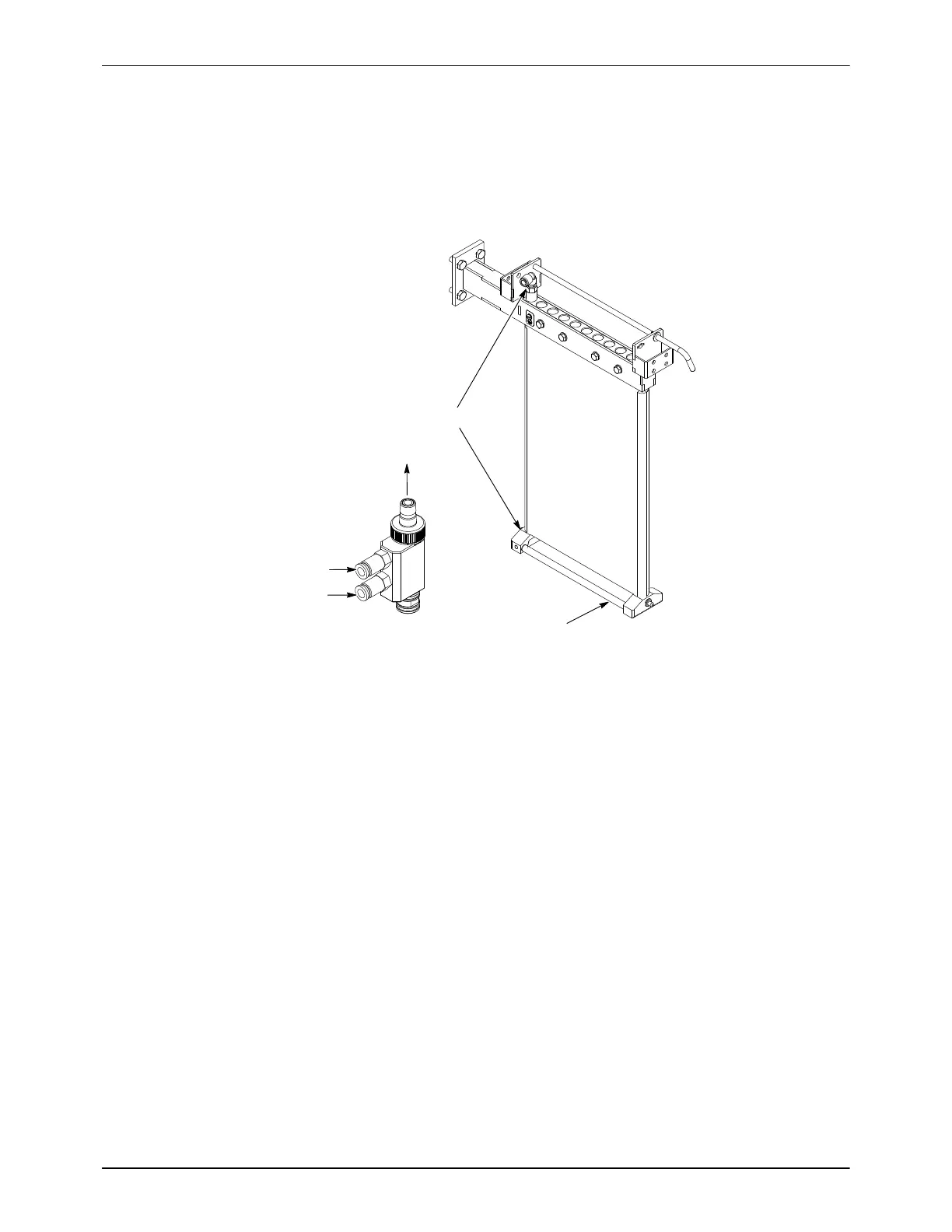

Lance Assemblies

One, two, or three lance assemblies are attached to the lift assembly. Up to

nine in-line powder pumps can be mounted on each lance assembly. The

pumps are installed in the lance ports, and held into place with a retaining

rod. If a lance pump port is not used, it is plugged with a plug module.

FLUIDIZED

1

2

IN−LINE PUMP

ATOMIZING AIR

FLOW AIR

POWDER

Figure 2-3 Lance Assembly

1. Fluidizing latch block assembly 2. Fluidizing bars

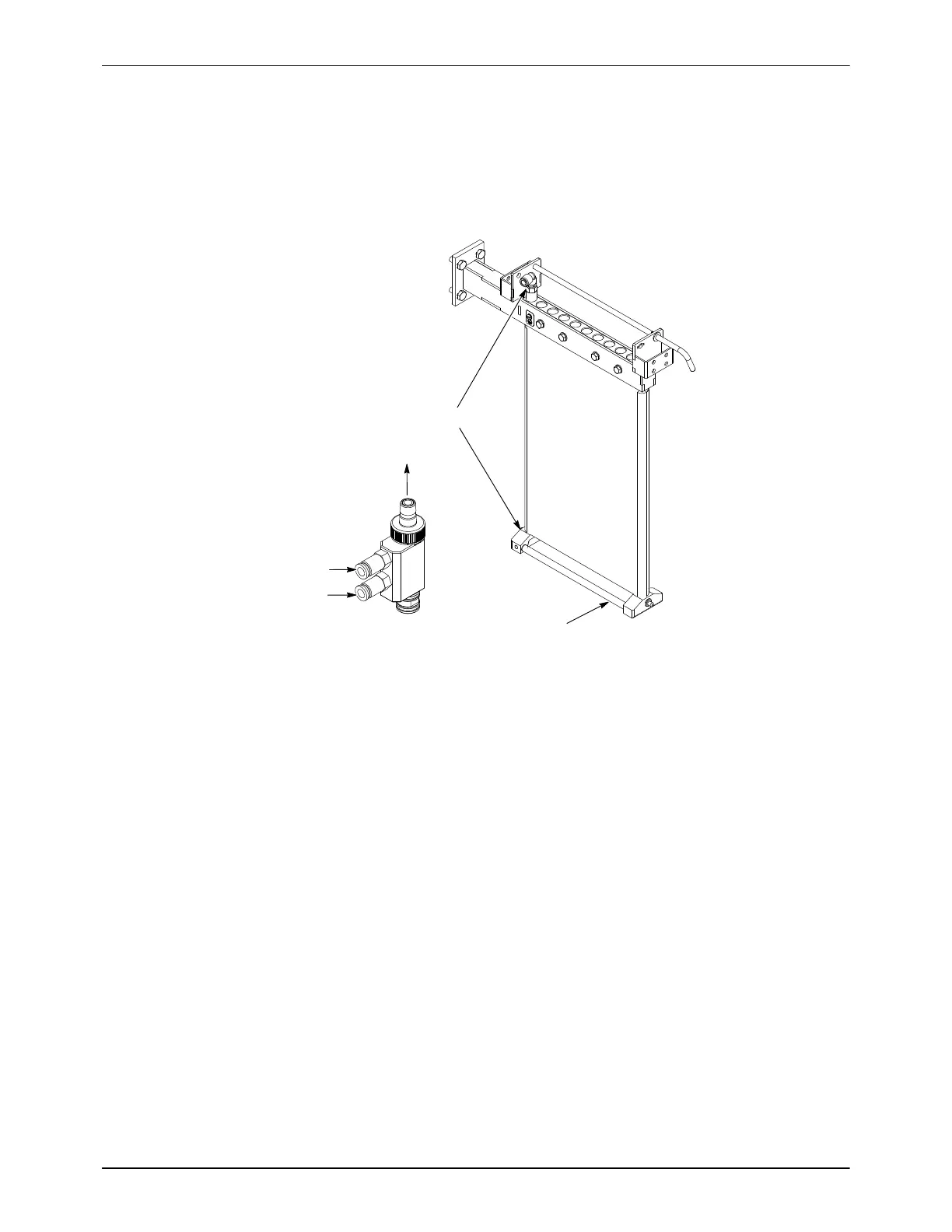

Lift Assembly

The lift assembly uses a locking air cylinder to raise and lower the lance

assemblies in and out of the feed hoppers or powder boxes:

S If a feed hopper is selected as the powder source, the lance is lowered

until it is a set distance above the fluidizing plate, as determined by the

position of a proximity sensor on the lift cylinder.

S If a powder box is selected, the lance is lowered until the level sensor on

the lance contacts the powder, and then lowered gradually as the

powder is used.

The cylinder motion and locking action are controlled by three solenoid

valves that are part of the control manifold on the roof of the feed center.

The lift cylinder has a spring-actuated locking mechanism released by air

pressure. The cylinder is locked when the air line is vented; unlocked when

pressurized. The cylinder also uses a balancing air circuit, which applies air

pressure to both sides of the piston to prevent lurching when restarting

motion after a locked stop.

Loading...

Loading...