Installation

3-11

Part 1602966−05

E 2015 Nordson Corporation

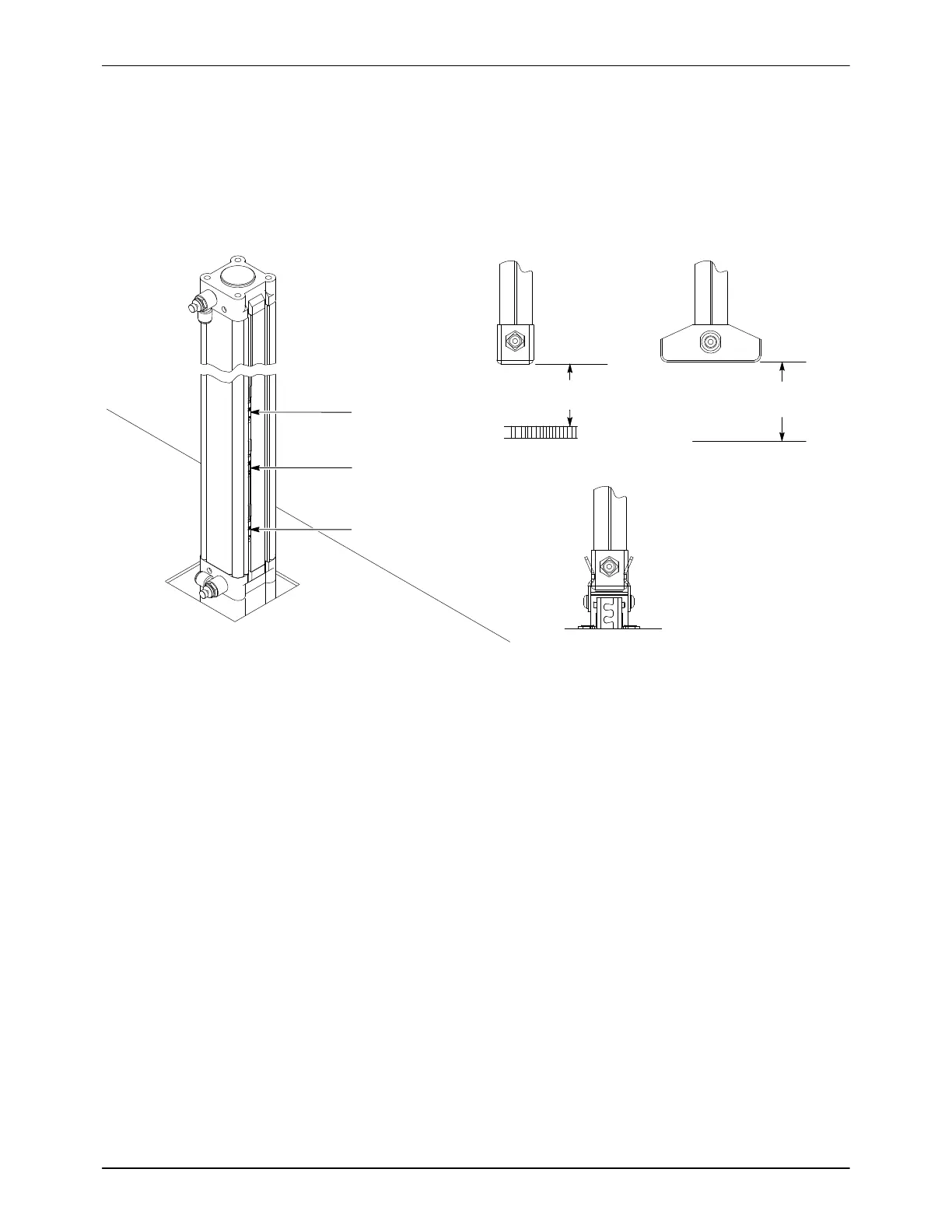

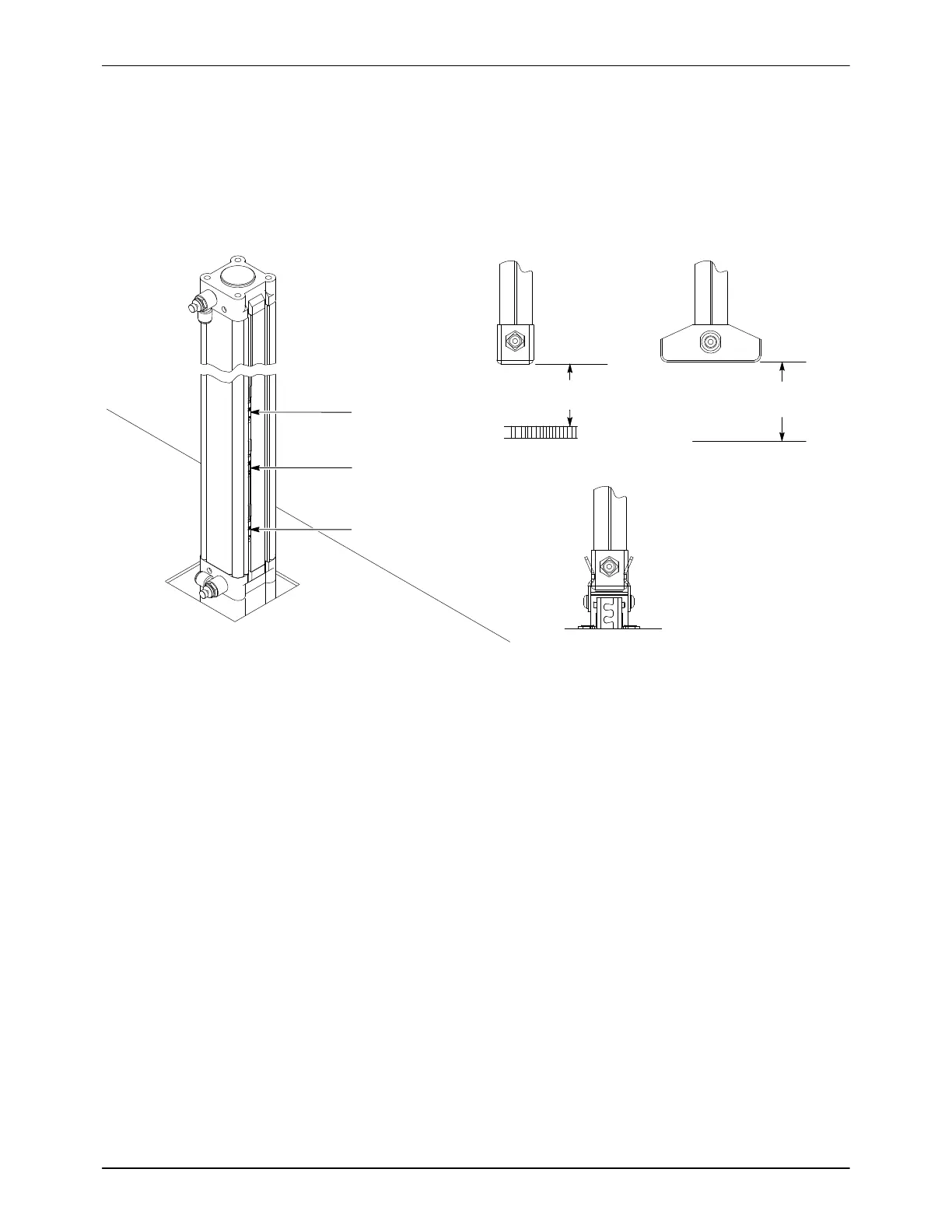

Lift Cylinder Proximity Switch Adjustment

There are three proximity switches on the lift cylinder. They sense the

position of the cylinder piston, and therefore the bottom of the lance, in

relation to the hopper fluidizing plate, the bottom of a powder box, and the

purge manifold. Each switch has an LED that turns on when the switch is

closed through the use of a magnet embedded in the cylinder piston.

LS306

Hopper

LS307

Box

LS308

Purge

Hopper Box

Purge

1.0”

(25.4 mm)

1.0”

(25.4 mm)

Fluidizing Plate

Bottom of Box

Figure 3-19 Proximity Switches and Settings (Typical Lift Cylinder Shown)

NOTE: The lance assembly will stop at the Box or Hopper switch,

depending on the powder source selected. To override the switch, continue

to hold the Lance Control switch in the down position for 3 seconds after it

stops.

LS308 Purge Switch (Bottom Switch): Lower the lance down onto the

stop bolt. Slide the switch up and down while watching the LED. Mark the

positions at which the switch LED turns on in both directions, then secure

the switch midway between the on positions.

LS307 Box Switch (Middle Switch): Position an empty powder box on the

table. Lower the lance assembly down until it is at the recommended height

above the bottom of the box. Slide the switch up or down until the switch

LED turns on. Mark the positions at which the switch LED turns on in both

directions, then secure the switch midway between the on positions.

LS306 Hopper Switch (Top Switch): Position an empty hopper on the

table. Lower the lance assembly down until it is at the recommended height

above the fluidizing plate. Slide the switch up or down until the switch LED

turns on. Mark the positions at which the switch LED turns on in both

directions, then secure the switch midway between the on positions.

Loading...

Loading...