Operation

5-5

Part 1602966−05

E 2015 Nordson Corporation

3. Make sure compressed air is being supplied to the feed center at above

5.5 bar (80 psi) and that air pressures are adjusted properly. See Figure

2-8 for regulator locations.

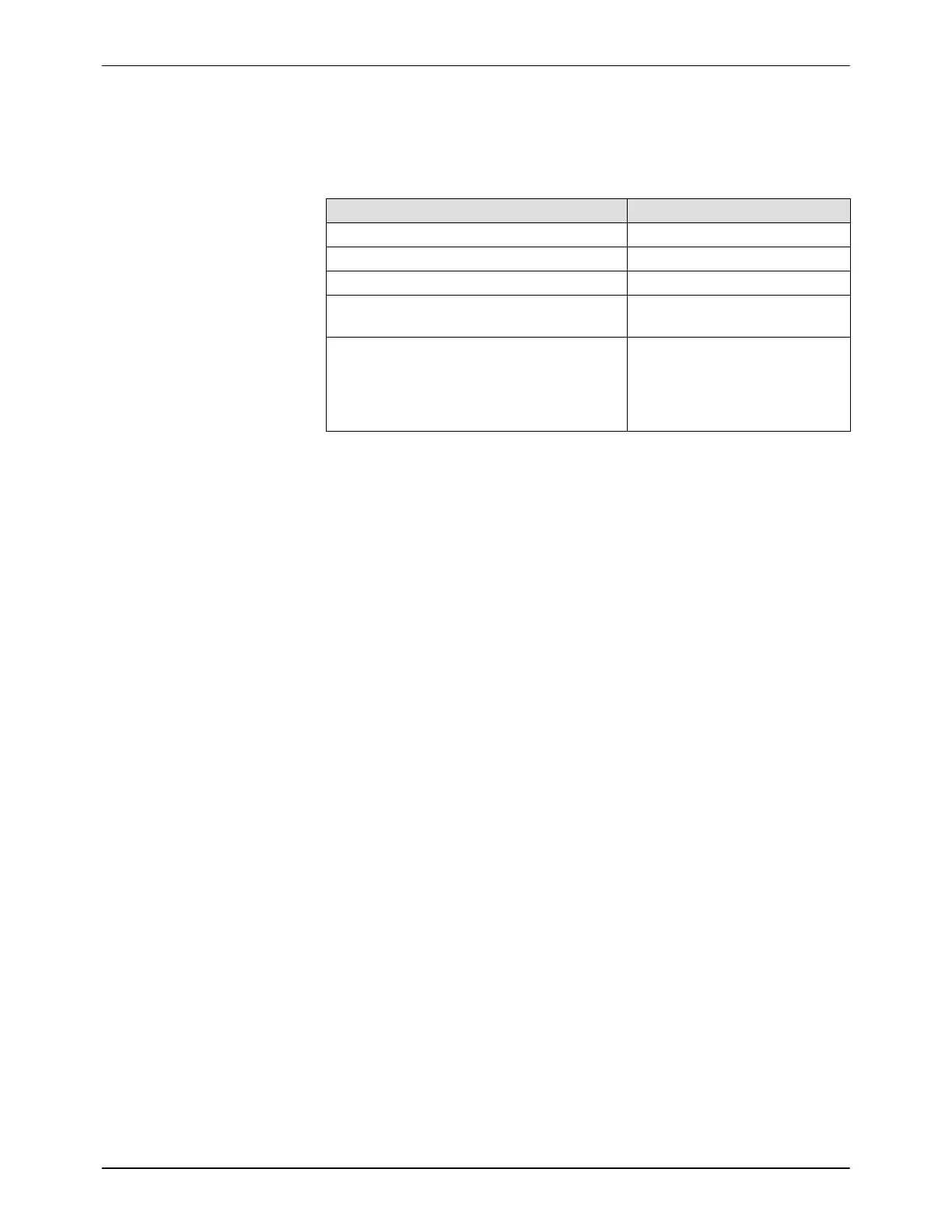

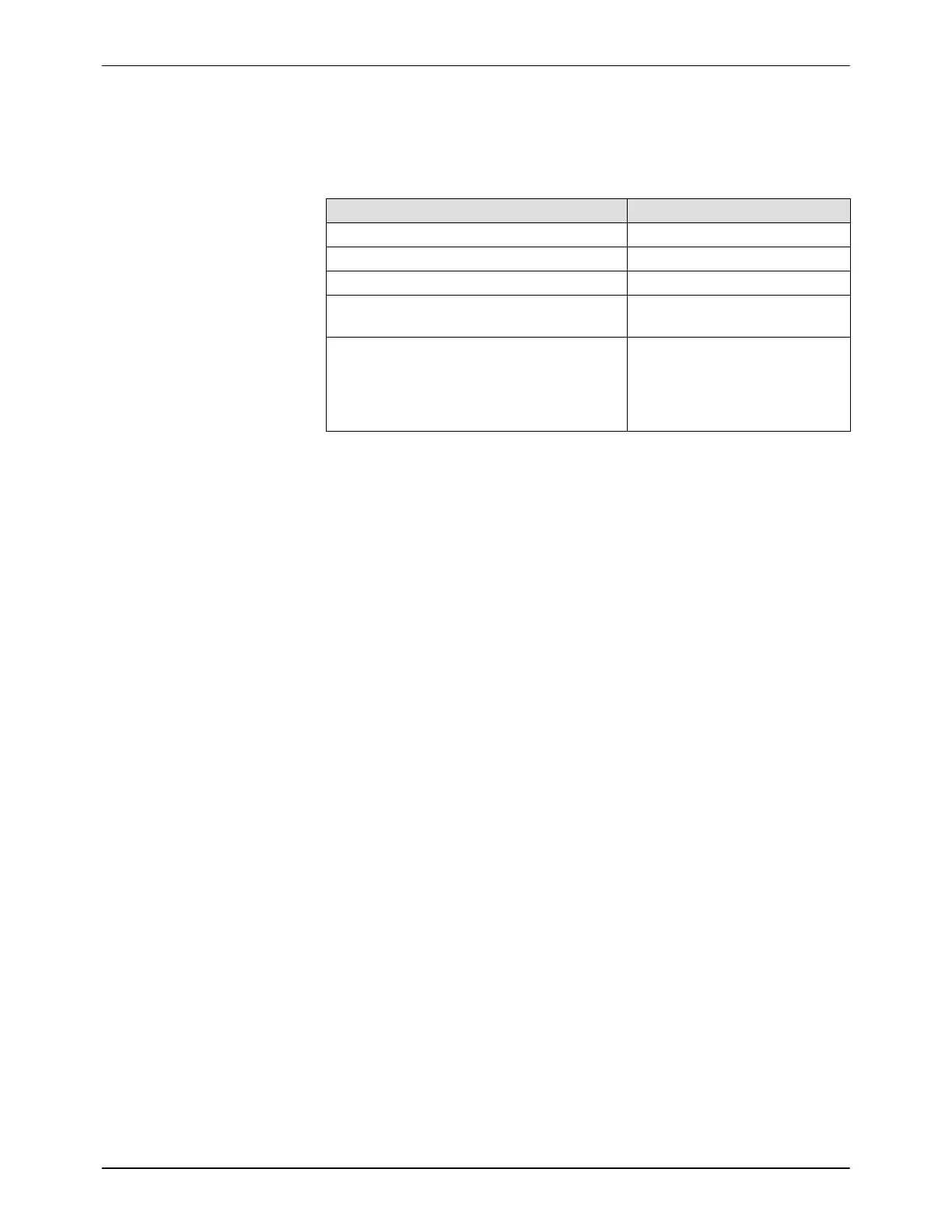

Table 5-1 Feed Center Air Pressure Settings

Air Pressure Typical Setting

Lance Fluidizing (typical) 0.3 bar (5 psi) 0.03 Mpa

Feed Hopper Fluidizing (typical) 0.3 bar (5 psi) 0.03 Mpa

Purge 5.5 bar (80 psi) 0.55 Mpa

Purge Clamp 3.4−4.1 bar (50−60 psi)

0.34−0.41 Mpa

Lance Cylinder:

Up, 1 Lance

Up, 2 Lances

Up, 3 Lances

Down

4.1 bar (60 psi) 0.41 Mpa

4.8 bar (70 psi) 0.48 Mpa

5.5 bar (80 psi) 0.55 Mpa

3.4 bar (50 psi) 0.34 Mpa

4. Move a feed hopper or box into the feed center, and position it below the

lance assembly, adjusting the table stops as necessary. Select Hopper

or Box with the Powder Source Selector switch on the control panel.

5. If using a feed hopper:

a. Connect the fluidizing tubing to the fitting on the feed hopper

plenum.

b. Fill the hopper 2/3 full of powder. Do not overfill; the powder

expands when fluidizing air is turned on.

c. Gradually increase the feed hopper fluidizing air pressure until the

powder is gently boiling.

d. Lower the lance assembly into the hopper with the Lance Control

switch. The lance stops automatically above the fluidizing plate.

6. If using a powder box:

a. Turn on the vibratory table.

b. Lower the lance assembly into the box with the Lance Control

Selector switch (left for down) until the fluidizing bars and end of the

level sensor are covered by powder.

c. Gradually increase the lance fluidizing air pressure until the powder

is gently boiling.

7. Make sure the sieve discharge pan is positioned so that the discharge

tube directs the screened powder into the feed hopper or box. Loosen

the deck clamps to rotate the pan, then re-clamp the deck.

8. If used, make sure the reclaim and virgin powder transfer hoses are

connected to the tubing stubs on the sieve deck. Turn on the reclaim

transfer pump and enable the virgin transfer pump.

9. Turn on the sieve.

10. Turn on the spray guns and start spraying powder. Make sure

everything is working correctly before starting production.

Loading...

Loading...