- 13 -

Printing on Various Papers

z

Die-cut labels that are used in Gap Mode must satisfy the following conditions.

The transparency of the label part (including both the label and the label liner) must be below 25%.

The liners must be within a range of 10% to 45% transparent. However, the transparency of the liners must be more than 1.8

times the transparency of the label part.

z

Die-cut labels that are used in Gap Mode cannot use transparent liners or labels.

z

Die-cut labels that are used in Black Mark Mode cannot use transparent liners.

z

Use continuous labels that have been smoothed on both edges and have been dry edge processed. Recommended

specifications are for paper that has 2 mm of liner on both edges. Please refer to the “Maintenance Guide” for details.

z

Thermal paper will become discolored and deformed by heat used for fusing. Do not use it.

z

Use film that can withstand heat up to 230°C. Use of film that is not heat resistant creates the risk of film deformation by heat

used for fusing, paper jams, and device malfunction.

z

Do not use a liner on which glue is smeared. It will not feed correctly in the equipment. In the worst case, it could damage the

equipment.

z

Cast-coated paper is not recommended. Printing quality cannot be guaranteed when it is used.

z

If the paper length, label length, or black Mark Interval for a single sheet is less than 4 inches, blank sheets may be printed to

satisfy the paper length that can be fed.

z

When printing on paper that is cut to less than 152 mm (6 inches) long in the direction that media is fed, it may feed at an

angle.

If this happens, print it so there is a continuous length that is longer than 152 mm (6 inches).

z

When printing on paper that is very narrow (25.4 mm (1 inch)), it may feed at an angle at about 80 mm from the cut trailing

edge.

z

When printing on inside winding paper that is very narrow (25.4 mm (1 inch)), smeared or smudged printing may occur near

the cut trailing edge as the roll diameter gets smaller.

z

When printing on inside winding paper that is very narrow (25.4 mm (1 inch)), slight damage may occur at the leading edge

as the roll diameter gets smaller.

z

Use of the types of paper below is not supported.

Paper whose roll surfaces are not cut cleanly.

Paper that is connected part way through by tape, etc.

Label paper without backing paper with paste on the front surface

Paper whose labels are easy to peel or are peeling

Paper with paste squeezing out onto the base paper area or affixed to the label surface

Paper that is folded or bent

Paper that has holes in it

Paper that is notched

Paper that has perforations

Paper with different size labels on a single roll

Paper with different paper widths on a single roll

Media that has liners and labels that are both transparent (cannot be used even if it has black marks)

Continuous paper that is transparent (cannot be used even if it has black marks)

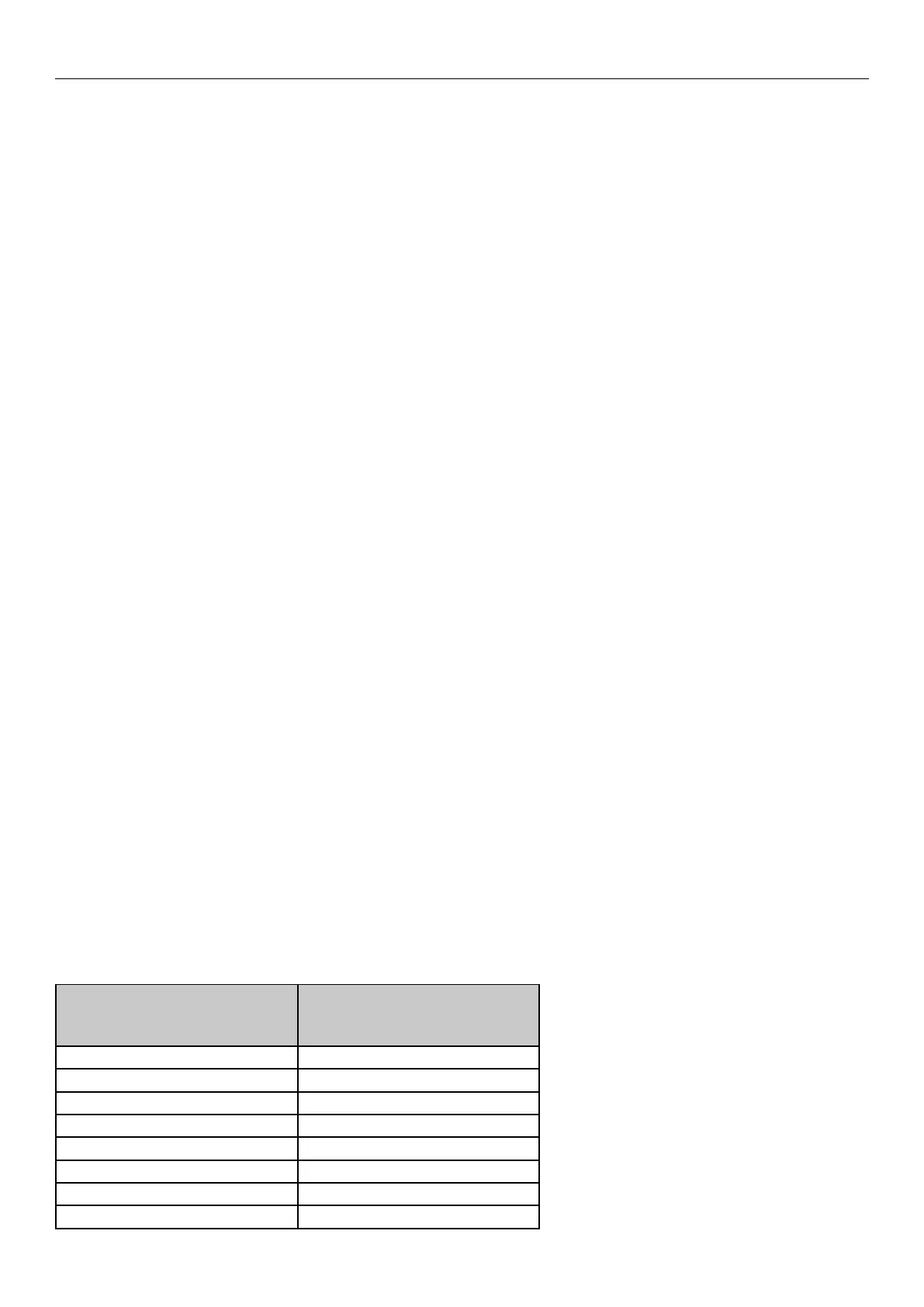

Setting the Paper Weight

Set the printer and printer driver paper weight according to the weight of the paper to be used.

Paper Weight

(Total thickness including

backing paper)

Setting Value of the

Media Weight

76 to 95 μm Light

96 to 140 μm Medium Light

141 to 159 μm Medium

160 to 180 μm Medium Heavy

181 to 199 μm Heavy

200 to 214 μm Ultra Heavy1

215 to 229 μm Ultra Heavy2

230 to 249 μm Ultra Heavy3

Loading...

Loading...