6-4 Service Manual

XZAC4219-05

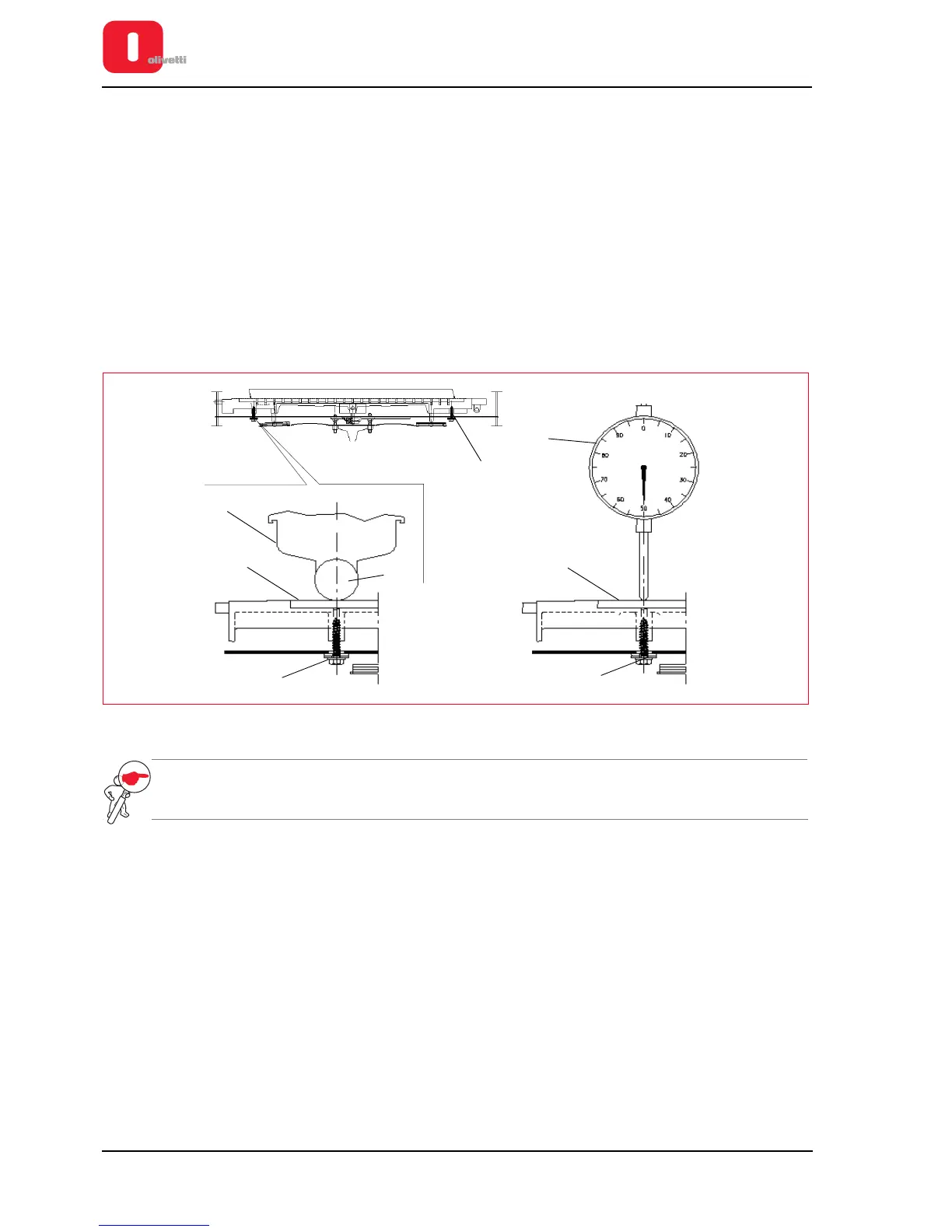

Adjusting the print bar (where torsion bar present)

• MACHINE STATUS

– Printer switched off and without casing.

– Printhead positioned co-axially with the axis of the screw used to make the adjustment.

• CONDITIONS TO BE CHECKED

Distance of 0.4 - 0.5 mm between print bar (2) and feeler roller (3).

• PROCEDURE

– Disassemble the mechanical unit. See the section “Mechanical assy disassembly/reassembly” on page 7 - 6.

– Bring the print unit to the writing position; then, using the two screws (1), adjust the print bar (2) in contact

with the feeler roller (3), positioning the head (4) in axis with the screw.

– Lift the print unit and move the print bar (2) up by 0.35 - 0.45 mm, operating on the screw (1) and checking

movement with a comparator (5) positioned on the axis of the screw.

– Repeat the operation on the other screw, from the opposite side of the structure.

Figure 6 - 3 Adjusting the print bar

NOTE: check the print quality with OFF-LINE testing. See the section “Activating and deactivating the print

test” on page 2 - 10.

Loading...

Loading...