XZAC4219-05 Service Manual

5-19

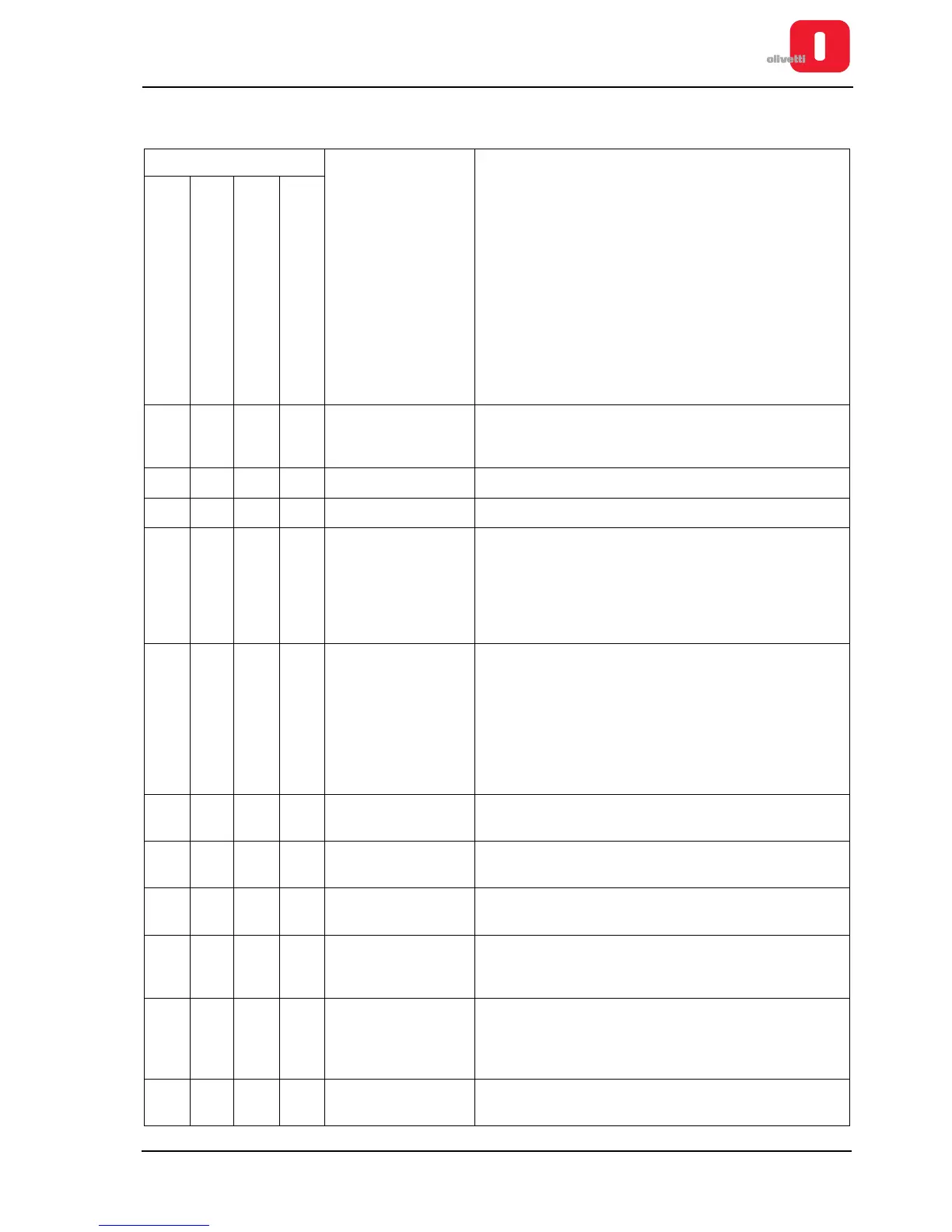

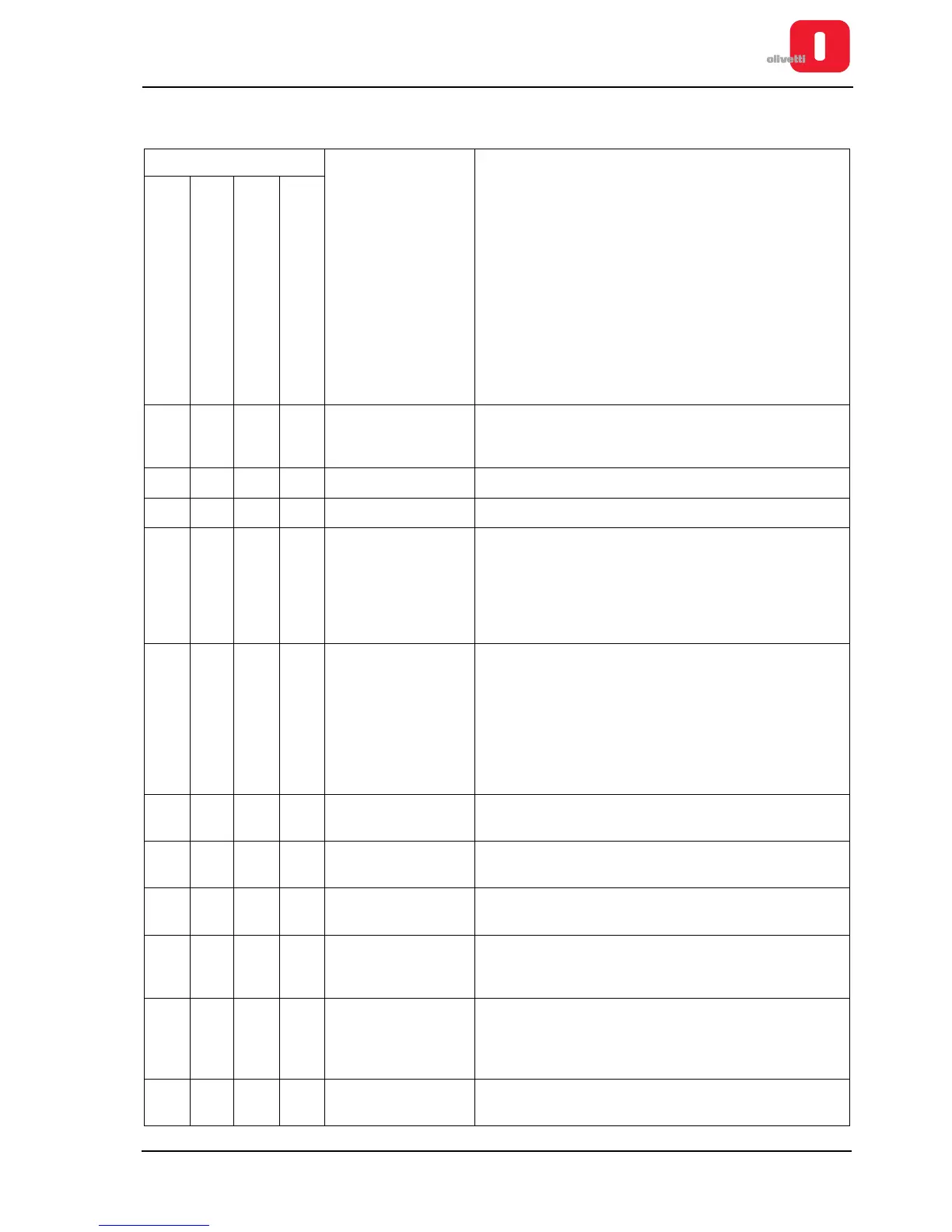

Faults with document handling

Fault

Possible cause Solution

The machine does not

introduce/eject the document

The document is

fed crookedly

The document

iswrinkled

The document

has irregular line feeds

XXXX

Document not acc.

to specs

Check the dimensions and the type of the document . See

“DOCUMENTS THAT CAN BE HANDLED BY THE BASIC

MACHINE” on page 1 - 3

XXXXDocument ruined Use another document.

XXXClosing levers open Lower the lever for closure.

XX

Front

photosensors

fault

1 Carry out the calibration procedure

.

See the section

“CALIBRATING THE PHOTOSENSORS” on page 4 -

18

2

Clean and if necessary replace the fault

photosensor

.

See

“PROCEDURE FOR CLEANING / REPLACING

THE PHOTOSENSORS” on page 6 - 2

X

Paper

photosensor

fault

1

Adjust the sensor position.

See the section

“Adjusting

Paper Photosensor” on page 6 - 8

2 Carry out the calibration procedure.

See

“CALIBRATING THE PHOTOSENSORS” on page 4 -

18

3

Clean and if necessary replace the fault

photosensor

.

See

“PROCEDURE FOR CLEANING / REPLACING

THE PHOTOSENSORS” on page 6 - 2

X Service motor fault

Replace the services motor. See the section “Services

motor disassembly/reassembly” on page 7 - 14

XX

Paper feed

motor fault

Replace the paper feed motor. See “Paper feed motor

disassembly/reassembly” on page 7 - 12

X

Adjustment of needle

roller incorrect

See “Adjusting the roller gears” on page 6 - 9

X

Print bar not adjusted

correctly

See “Adjusting the print bar (where torsion bar present)”

on page 6 - 4 or “Adjusting the print bar (where torsion bar

absent)” on page 6 - 5

X Band not adjusted

Adjust the printing band. See “Adjusting the print bar

parallelism and leaf spring load on the basic machine” on

page 6 - 6 or “Adjusting parallelism of print bar (without

torsion bar)” on page 6 - 7

X

Roller gears not

adjusted

Adjust the gears. See “Adjusting the roller gears” on

page 6 - 9

Loading...

Loading...