XZAC4219-05 Service Manual

6-7

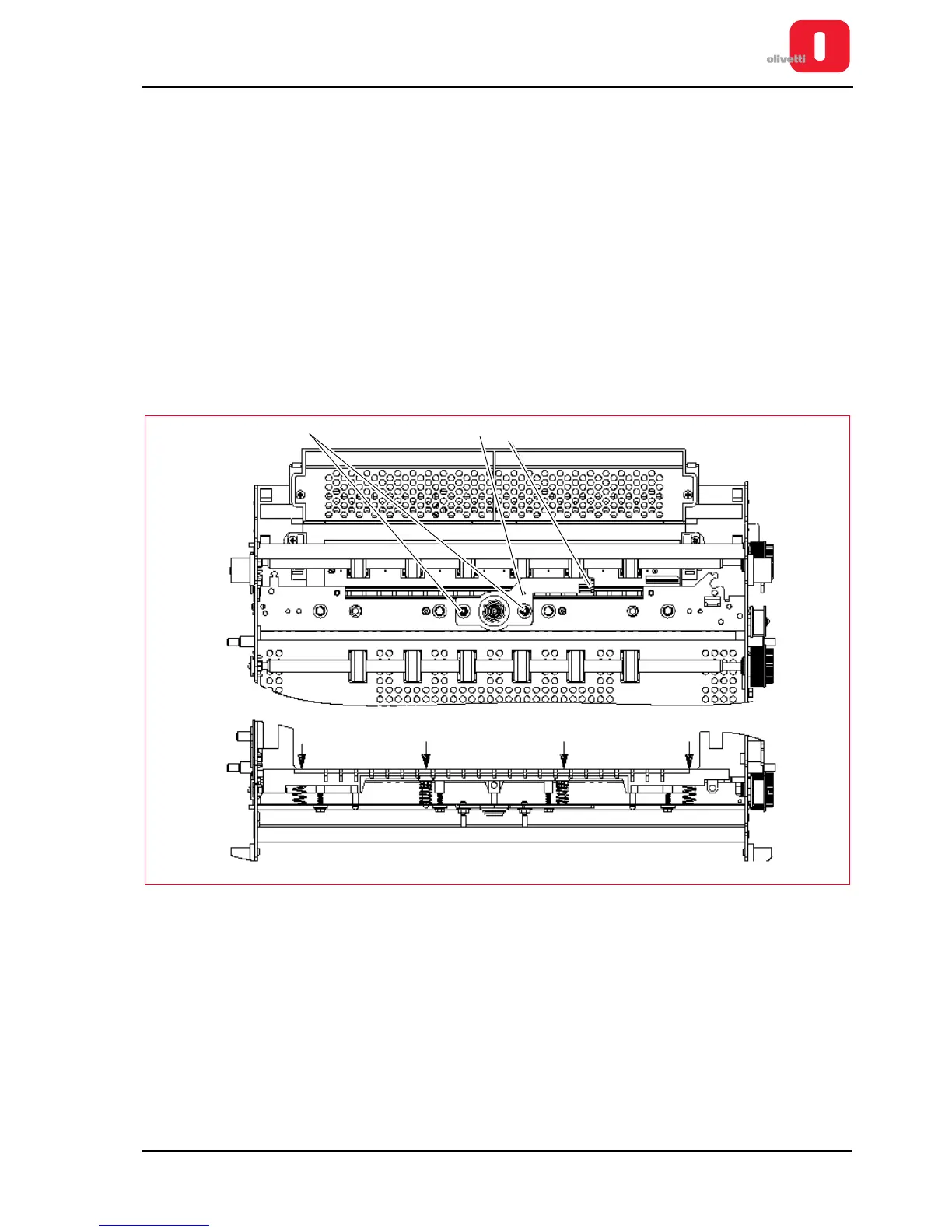

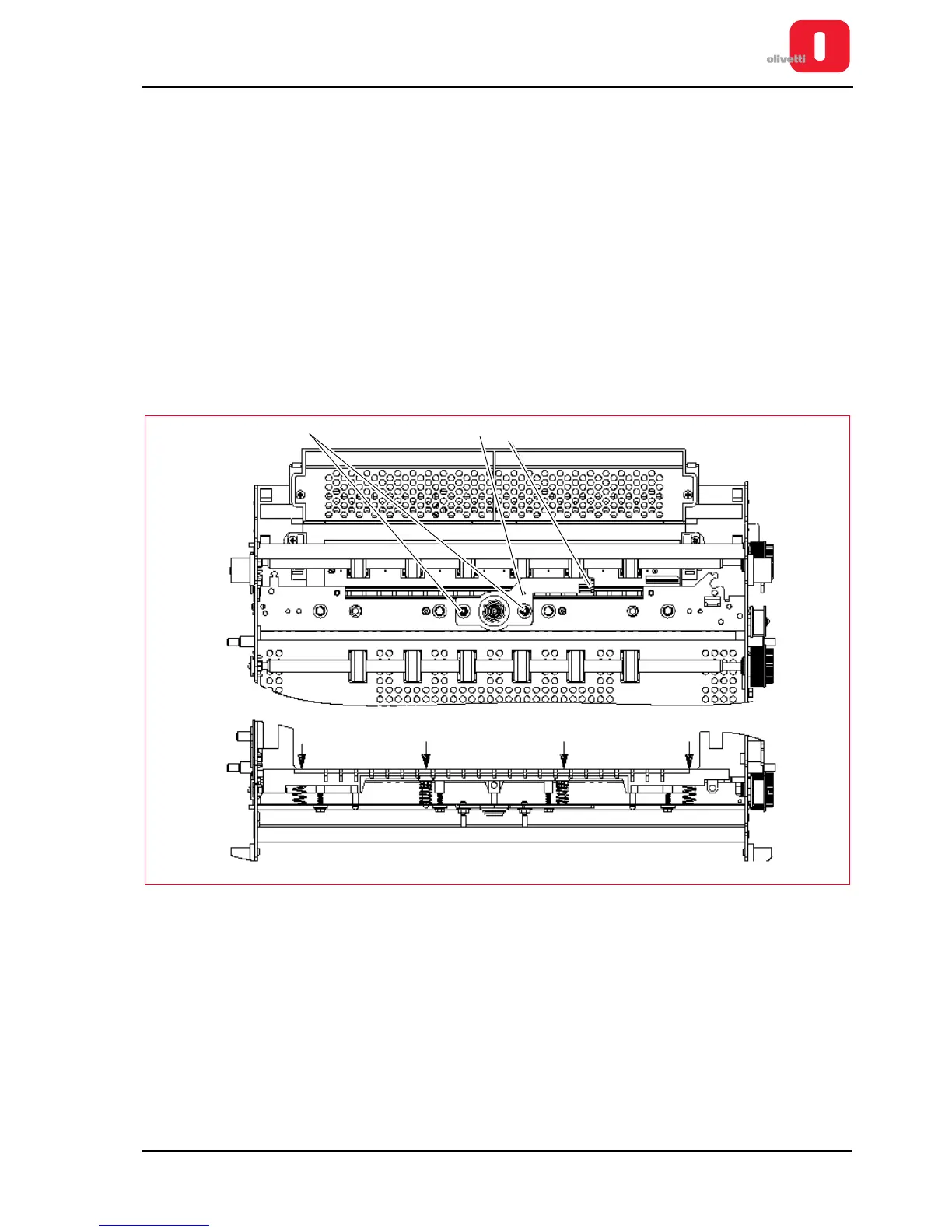

Adjusting parallelism of print bar (without torsion bar)

• MACHINE STATUS

Printer switched off and without casing.

• CONDITIONS TO BE CHECKED

Check print bar parallelism.

• PROCEDURE

– The bar perpendicularity adjustment lever (1) can be pre-regulated with tool code 9600303 according to

drawing code 395130U.

– For manual adjustment of the parallelism between the head and the print bar, rotate studs (2) counter

clockwise to move the bar close to the front of the matrix; rotate clockwise to move the bar to the rear of the

matrix.

– The parallelism indicator (3) can be used to check whether the corrections have been made.

– Move the carriage completely to the left and, using a comparator, push the print bar close to the feeler roller

with a dynamometer. A load of 350 g ± 20 g must correspond to a movement of 0.35 - 0.45 mm. Repeat the

procedure on the right of the bar. Repeat the procedure for every adjustment screw of the bar.

Figure 6 - 6 Adjusting parallelism of print bar

Loading...

Loading...