4 - 27

4 Setting the Controller

Vision System FH/FHV/FZ5 Series User’s Manual (Z365)

4-4 Setting Operation Mode [Startup Settings]

4

4-4-1 Setting the Operation Mode

• Do not change the settings for image input processing items and do not change Camera

parameters in the system settings in Non-stop Adjustment Mode.

• Do not select [Transfer data] during Line1 while Non-stop Adjustment Mode Window is run-

ning. You cannot measure during data transfer. Make sure to set [Transfer data] before run-

ning.

• When [Parallel Execute] in [Operation mode setting] of System setting is [ON], the measure-

ment time might be longer since the Parallel processing effect is reduced.

The following processing items are supported in Non-Stop Adjustment Mode:

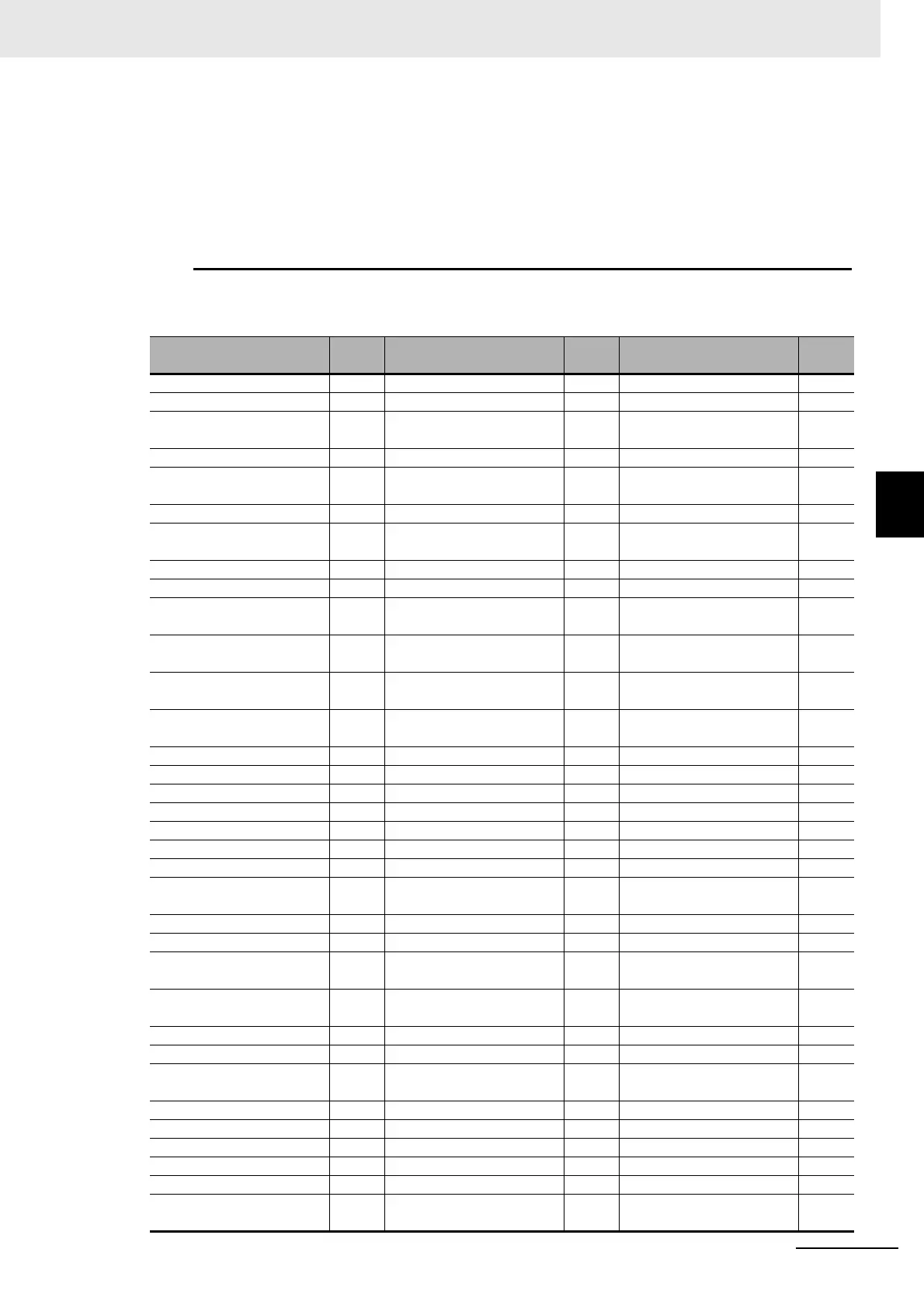

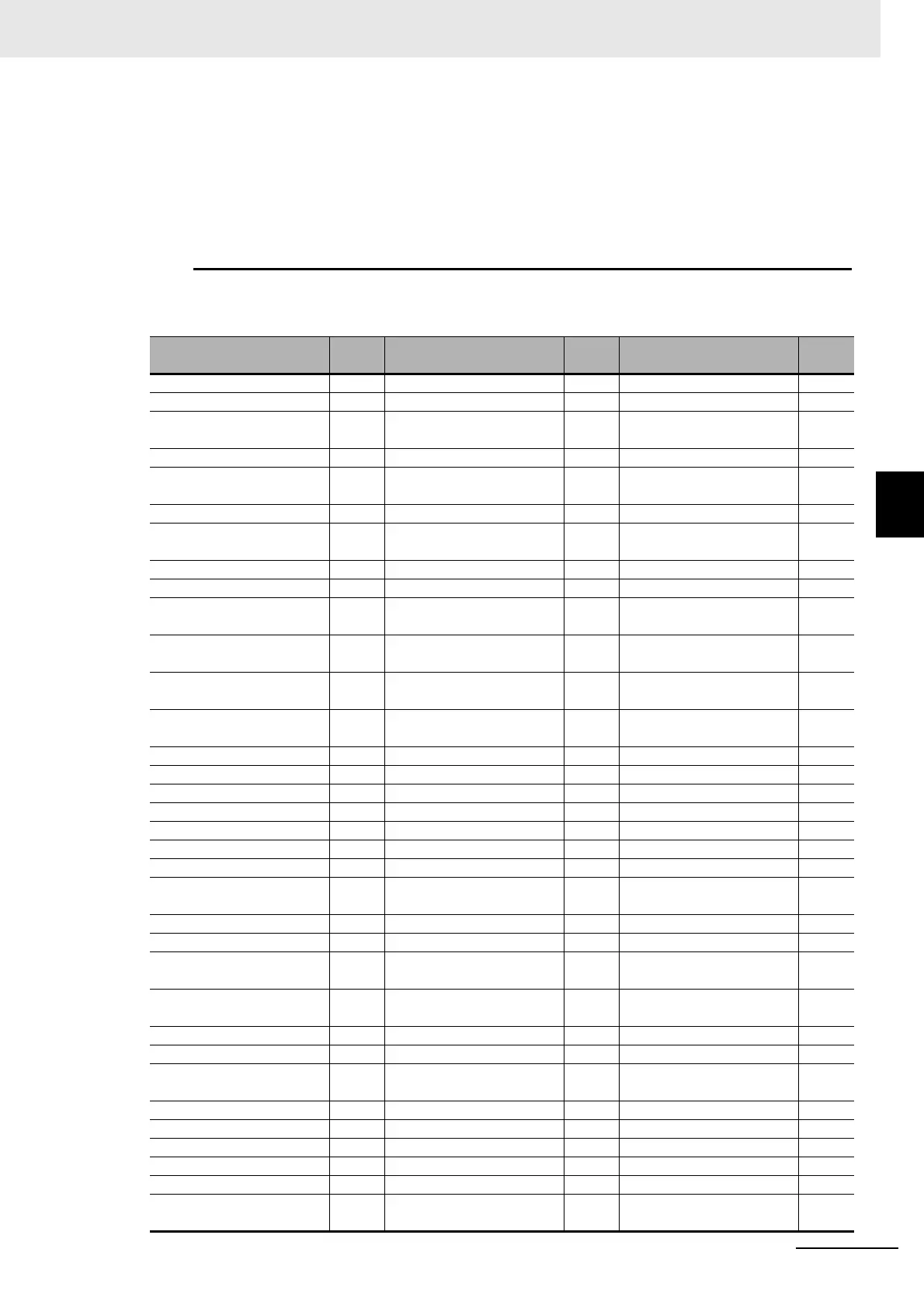

OK: Supported processing item, RST: Processing item with restricted support, ---: Unsupported processing item

Processing item

Sup-

port

Processing item

Sup-

port

Processing item

Sup-

port

Camera Image Input --- Back Ground Suppression OK Transfer Position Data OK

Camera Image Input FH --- Brightness Correct Filter OK Calc Axis Move OK

Camera Image Input FHV

---

Color Gray Filter

OK

Calc Axis Move by Multi-

point

OK

Camera Image Input HDR --- Extract Color Filter OK Detection Point OK

Camera Image Input HDR

Lite

---

Anti-Color Shading

OK

Camera Calibration

OK

Camera Switching OK Stripes Removal Filter II OK Data Save OK

Measurement Image

Switching

OK

Polar Transformation

OK

Conditional Branch

OK

Search OK Trapezoidal Correction OK End OK

Flexible Search OK Machine Simulator OK DI Branch ---

Sensitive Search

OK

Image Subtraction

RST(

*1

)

Control Flow Normal RST(

*2

)

ECM Search

OK

Advanced Filter

OK

Control Flow PLC Link RST(*

2)

EC Circle Search

OK

Panorama

OK

Control Flow Parallel RST(*

2)

Ec Corner

OK

Calculation

OK

Control Flow Fieldbus RST(*

2)

Ec Cross OK Line Regression OK Data Output OK

Shape Search II OK Circle Regression OK Parallel Data Output OK

Classification OK Precise Calibration OK Parallel Judgement Output OK

Edge Position OK User Data OK Fieldbus Data Output OK

Edge Pitch OK Get Unit Data OK Result Display OK

Scan Edge Position OK Set Unit Figure OK Display Image File OK

Scan Edge Width OK Get Unit Figure OK Display Last NG Image OK

Circular Scan Edge Posi-

tion

OK

Trend Monitor

---

OCR

OK

Color Data OK Image Logging OK OCR User Dictionary OK

Gravity and Area OK Image Conversion Logging

RST(

*3

)

Conveyor Calibration OK

Labeling

OK

Data Logging

RST(*3)

Conveyor Panorama Dis-

play

---

Label Data

OK

Elapsed Time

OK

Photometric Stereo Image

Input

OK

Defect OK Wait OK Display image hold OK

Precise Defect OK Focus OK Conditional execution (If) OK

Fine Matching

OK

Iris

OK

Conditional execution

(Else)

OK

Character Inspection OK Unit Macro OK loop OK

Date Verification OK Unit Calculation Macro OK Loop suspension OK

Model Dictionary OK Parallelize OK scene OK

2D Codes OK Parallelize Task OK Select execution (Select) OK

Circle Angle OK Statistics --- Select execution (Case) OK

Shape Search III

OK

Calibration Data Refer-

ence

OK

System information

OK

Loading...

Loading...