Parker EME

Setting up Compax3

192-120114 N5 C3I22T11 June 2008 171

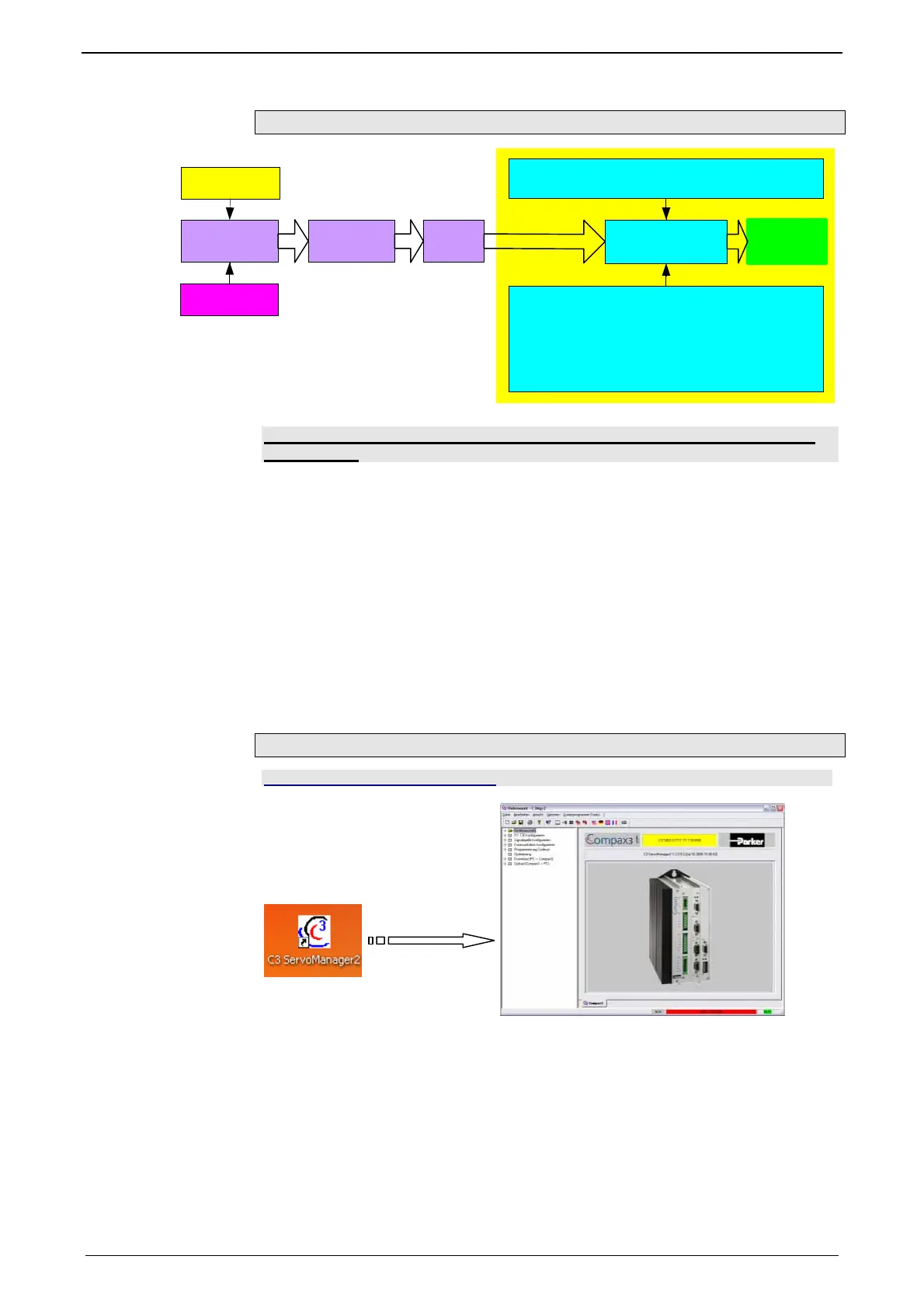

Proceeding during configuration, setup and optimization

Motorparameter

Applikations-

parameter

Konfiguration

autom.

Reglerentwurf

Stabile

Regelung

Inbetriebnahme

+

Optimierung

Applikations- und antriebsspezifische Eigenschaften

(Störgrößen)

Applikations – Anforderungen (Ziele) z.B.

- Minimierter Schleppfehler während der gesamten

Positonierung (z.B. Kurvenbetrieb)

- Minimierter Schleppfehler in der Zielposition

- Überschwingfreies Einlaufen in die Zielposition

- Schnelles Einschwingen in die Zielposition

- ...

Optimierte

Regelung

Overview of the processes during configuration and setup of the Compax3

drive system

The controller default settings are calculated from the configured motor and appli-

cation parameters with the aid of the automatic controller design which runs in the

background.

These controller presettings provide normally for a stable and robust control. Due

to continually rising application requirements, this presetting is often not sufficient,

so that further optimization of the control behavior is necessary.

This manual describes the setup and optimization procedure for Compax3.

In order to better understand the correlations and interactions, we will describe in

the first step the individual correlations and physical values, that are req uired for

the configuration and the prespecification of the control loops. In the following, the

manual will then describe the function blocks for the optimization implemented in

the servo controller as well as the setup tool.

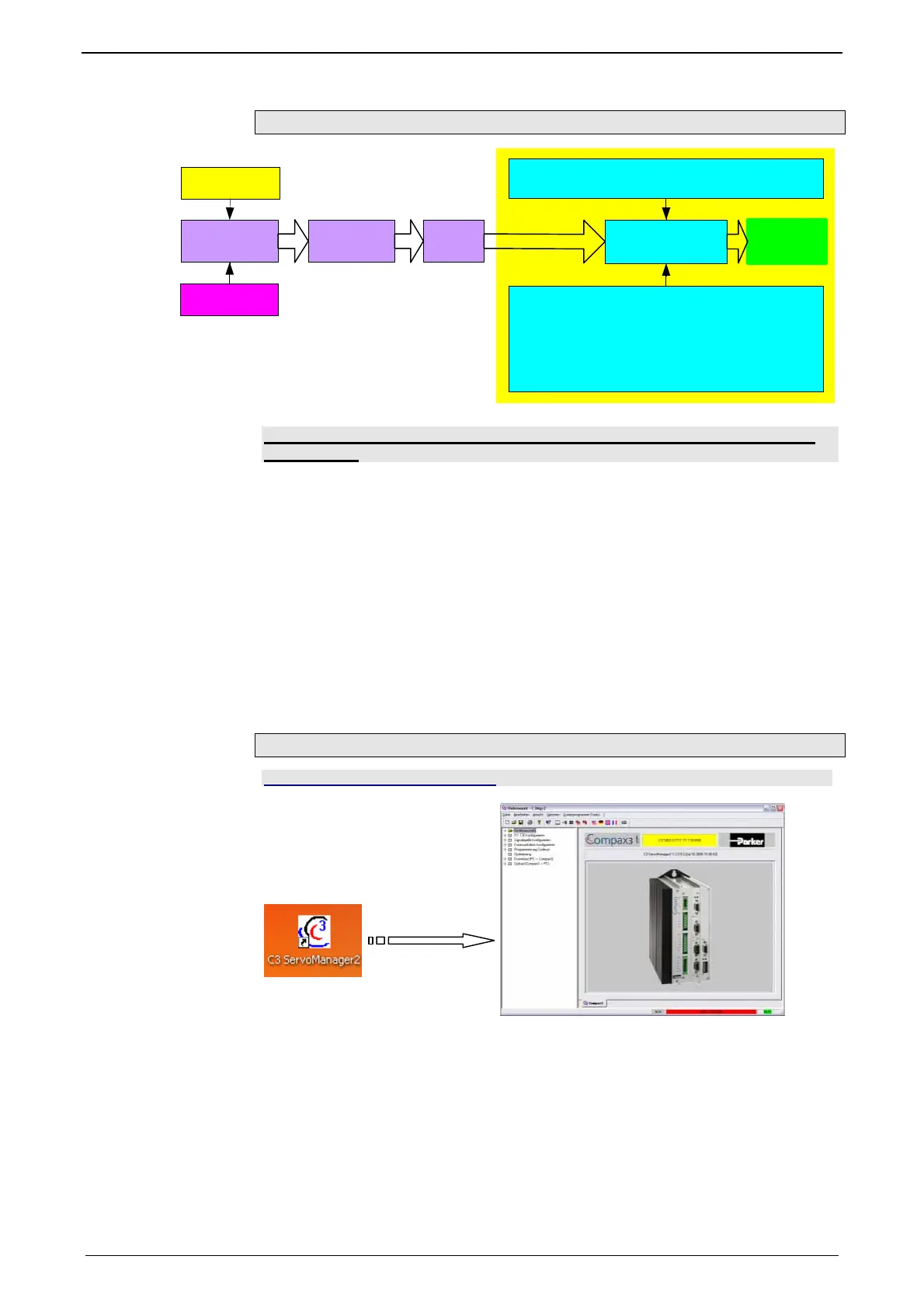

Software for supporting the configuration, setup and optimization

In this chapter you can read about:

Application parameters .................................................................................................... 172

The entry of the motor and application parameters is made with the C3 ServoMa-

nager2 (C3Mgr2.exe):

The configuration requires:

Loading...

Loading...