Parker EME

Compax3 Accessories

192-120114 N5 C3I22T11 June 2008 353

9.2.2. Motor output filter

In this chapter you can read about:

Motor output filter MDR01/04 ...........................................................................................353

Motor output filter MDR01/

01 ...........................................................................................353

Motor output filter MDR01/

02 ...........................................................................................354

Wiring of the motor output filter ........................................................................................354

We offer motor output filters for disturbance suppression when the motor connec-

ting cables are long (>20m):

Order code for motor output filter (for Compax3S, Compx3M >20m motor cable)

/

up to 6,3 A rated motor current

MDR

0 1 / 0 4

Up to 16 A rated motor current

MDR

0 1 / 0 1

up to 30 A rated motor current

MDR

0 1 / 0 2

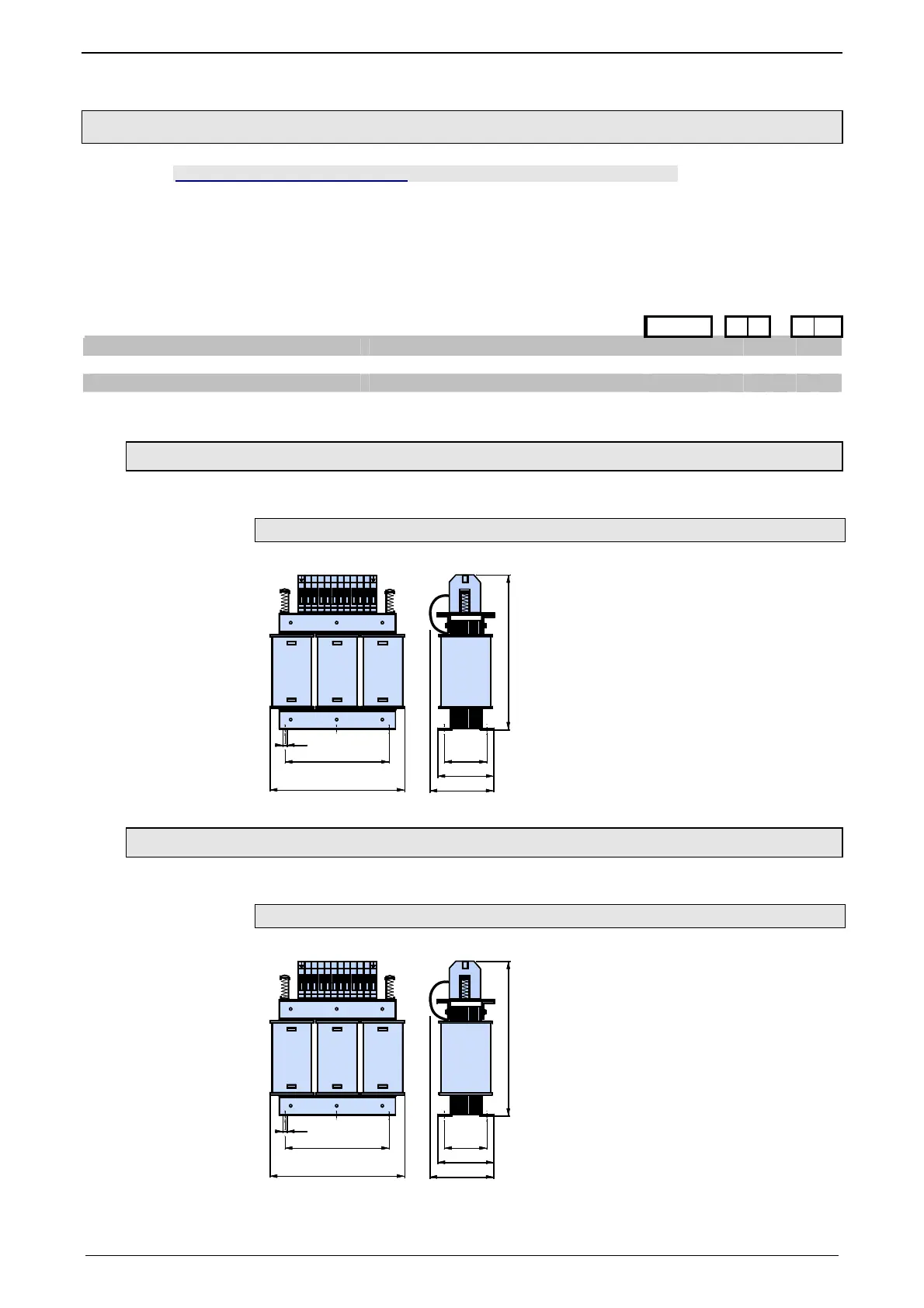

9.2.2.1 Motor output filter MDR01/04

up to 6.3A nominal motor current (3.6mH)

Dimensional drawing:

120

54

95

5

90

40

1

7

0

U1 V1 W1 + - U2 V2 W2 + -

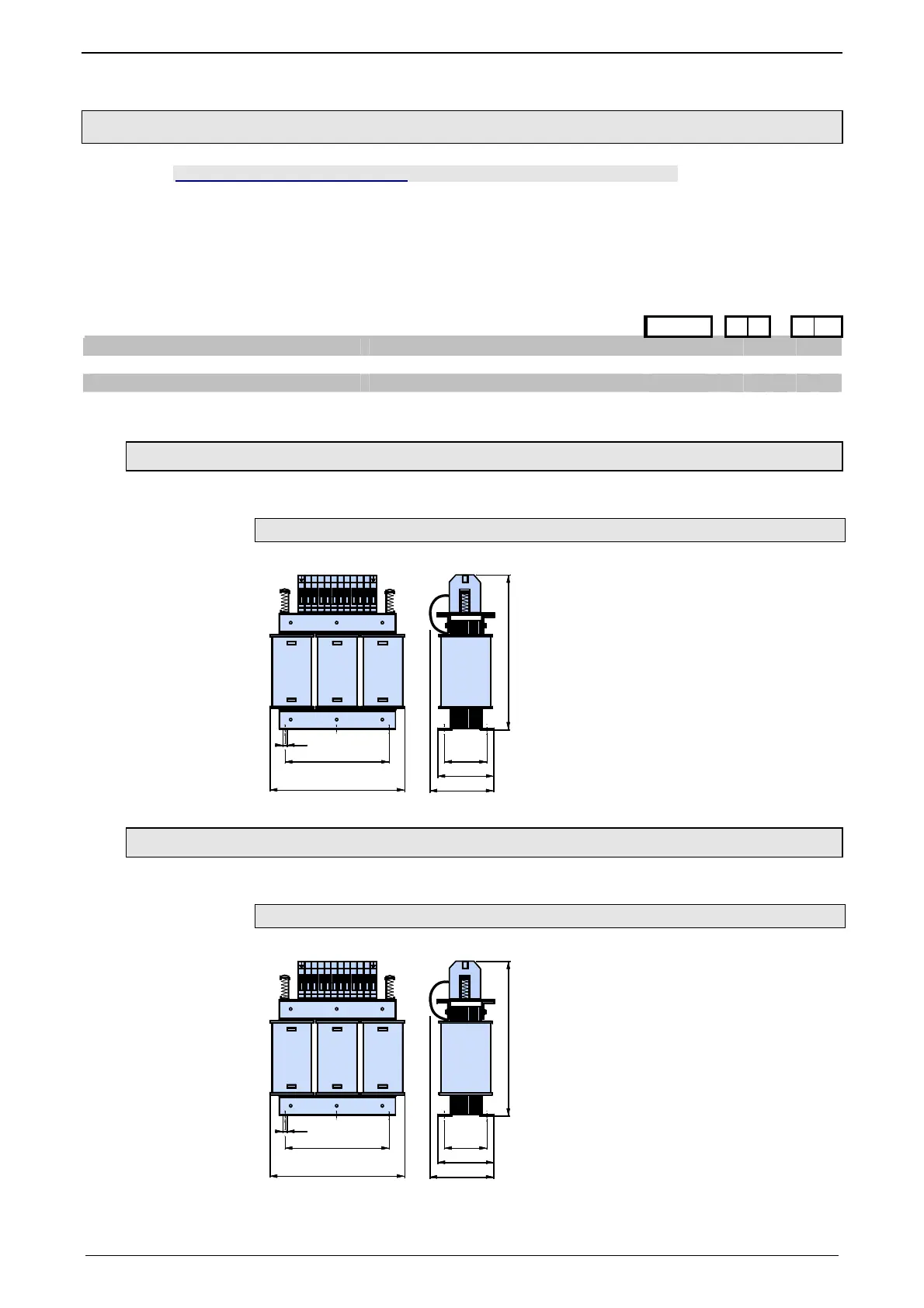

9.2.2.2 Motor output filter MDR01/01

Up to 16 A nominal motor current (2mH)

Dimensional drawing:

150

67

95

6

113

50

1

9

5

U1 V1 W1 + - U2 V2 W2 + -

Loading...

Loading...