Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

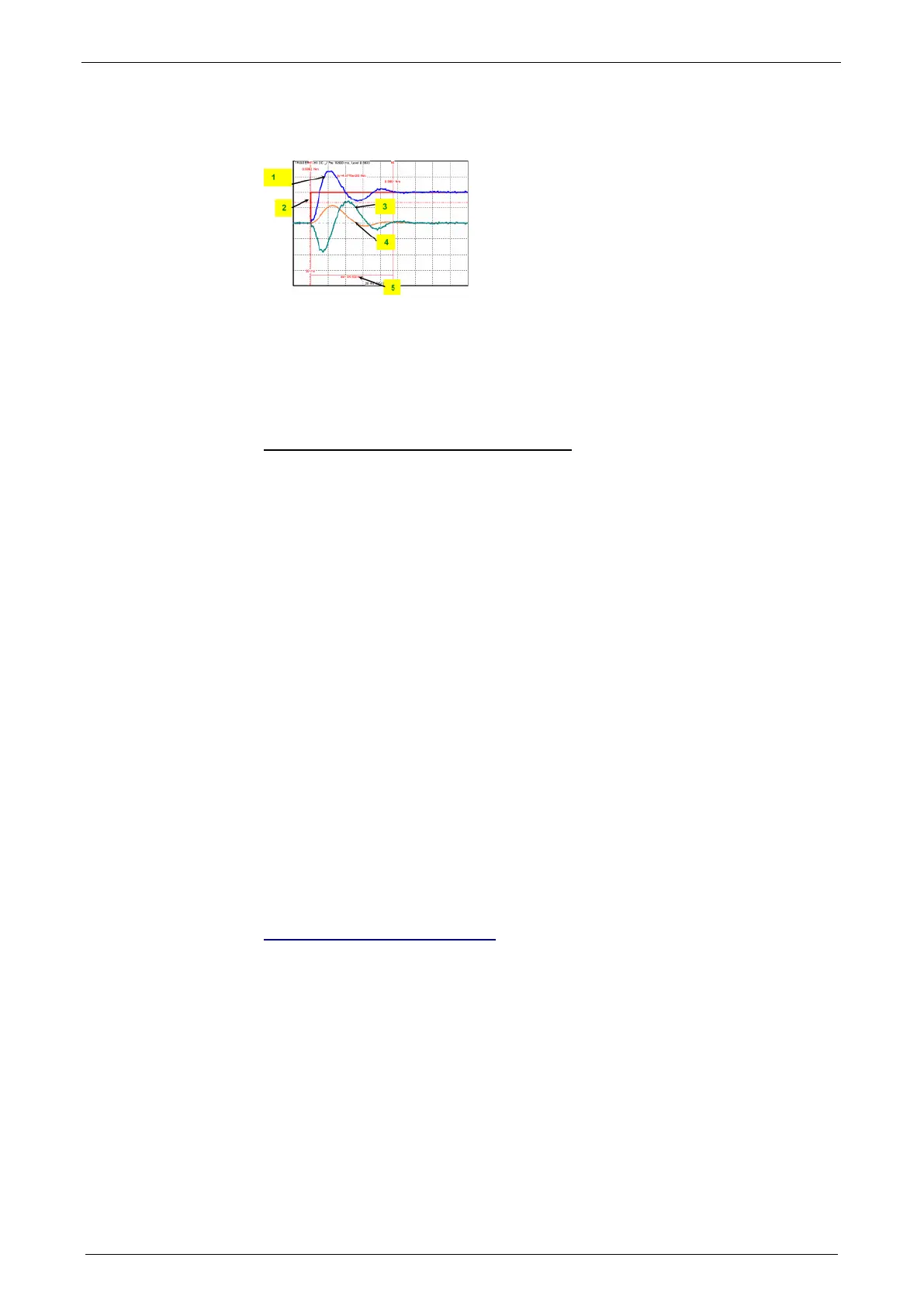

Disturbance jerk response

1: Compensation torque of the controller

2: Simulated disturbance torque

3: Actual speed

4: Following error

5: Settling Time

Correlation between the terms introduced

The introduced terms:

Stability

Damping

Velocity

Bandwidth

Setpoint and disturbance behavior

Control variable limitation

Replacement time constant

Rigidity

are related as follows:

A well-attenuated control features a stable control behavior.

The velocity of a control loop is a measure for the reaction rate of the controller to

the disturbance variable (disturbance behavior) as well as to the setpoint variable

(setpoint behavior).

The faster the control, the higher its bandwidth.

The term replacement time constant is an approximation and is only valid in a

defined scope1. In this scope, the control is always stable and well-attenuated.

If the controller does not work in the linear range, but the control variable of the

controller is within the limitation, the control slows down and the control difference

rises.

The stiffness represents the bandwidth of the velocity control. The higher the

stiffness value of the velocity control, the higher the bandwidth of the velocity

controller and the stiffer the drive.

Automated controller design

In this chapter you can read about:

Step response of the velocity loop depending on the optimization parameter "attenuation" and

"stiffness"....................................................................................................................... 203

D-term ........................................................................................................................... 203

Position loop .................................................................................................................. 203

The controller design takes place after the configuration immediately before the

configuration download into the device. The controller coefficients are preassigned

according to the design method of cross-ratios so that a stable control is achieved.

The automatic, robust controller design calculates the P and I terms of the

individual controllers (current, velocity, position) on the basis of the configured

motor and application parameters.

Loading...

Loading...