Parker EME

Setting up Compax3

192-120113 N08 C3I12T11 - December 2010

the control difference vanishes. In a digital control the static stiffness is above all

limited by the finite resolution of the position signal (the error must be at least one

quantization step, so that it can be detected by the reading system) and by

numerical resolution. Additional effects are for instance mechanical stiffness of the

mechanic components in the control path (e.g. load connection, guiding system) as

well as measurement errors of the measurement system.

Dynamic stiffness

In this chapter you can read about:

Traditional generation of a disturbance torque/force jerk ................................................ 201

Electronic simulation of a disturbance torque jerk with the disturbance current jerk........ 201

Disturbance jerk response ............................................................................................. 202

The dynamic stiffness is described by the ratio between the change in load torque

or in load force and the resulting position deviation (following error):

The higher this ratio (=dynamic stiffness), the higher the necessary change is load

torque in order to generate a defined following error.

The dynamic stiffness can be acquired from the disturbance jerk response.

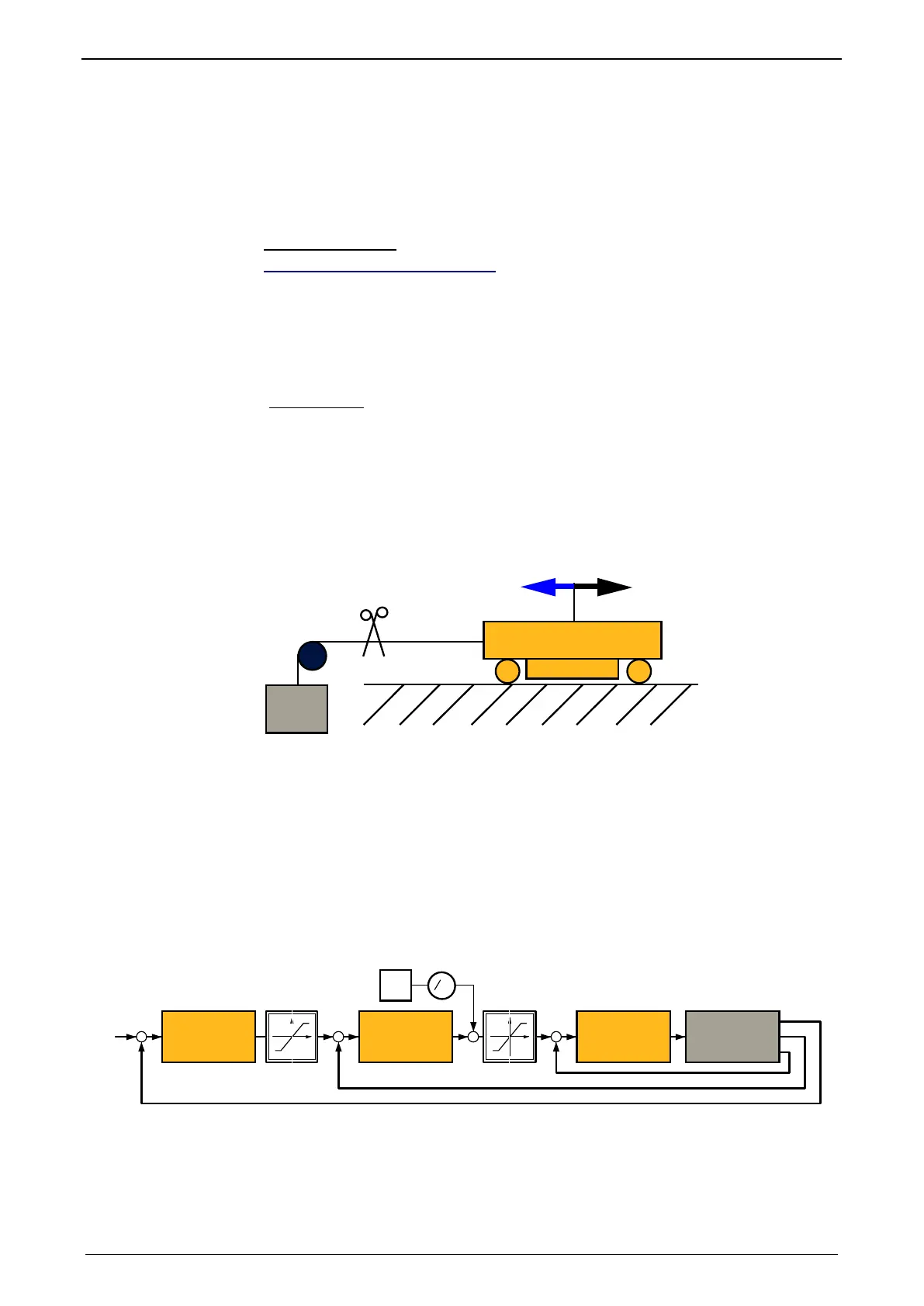

Traditional generation of a disturbance torque/force jerk

In settled state of the control, the motor force FM corresponds exactly to the load

force FG=m×g.

If the cord is cut through, the load force is eliminated abruptly and the controller

must first of all settle to the new situation.

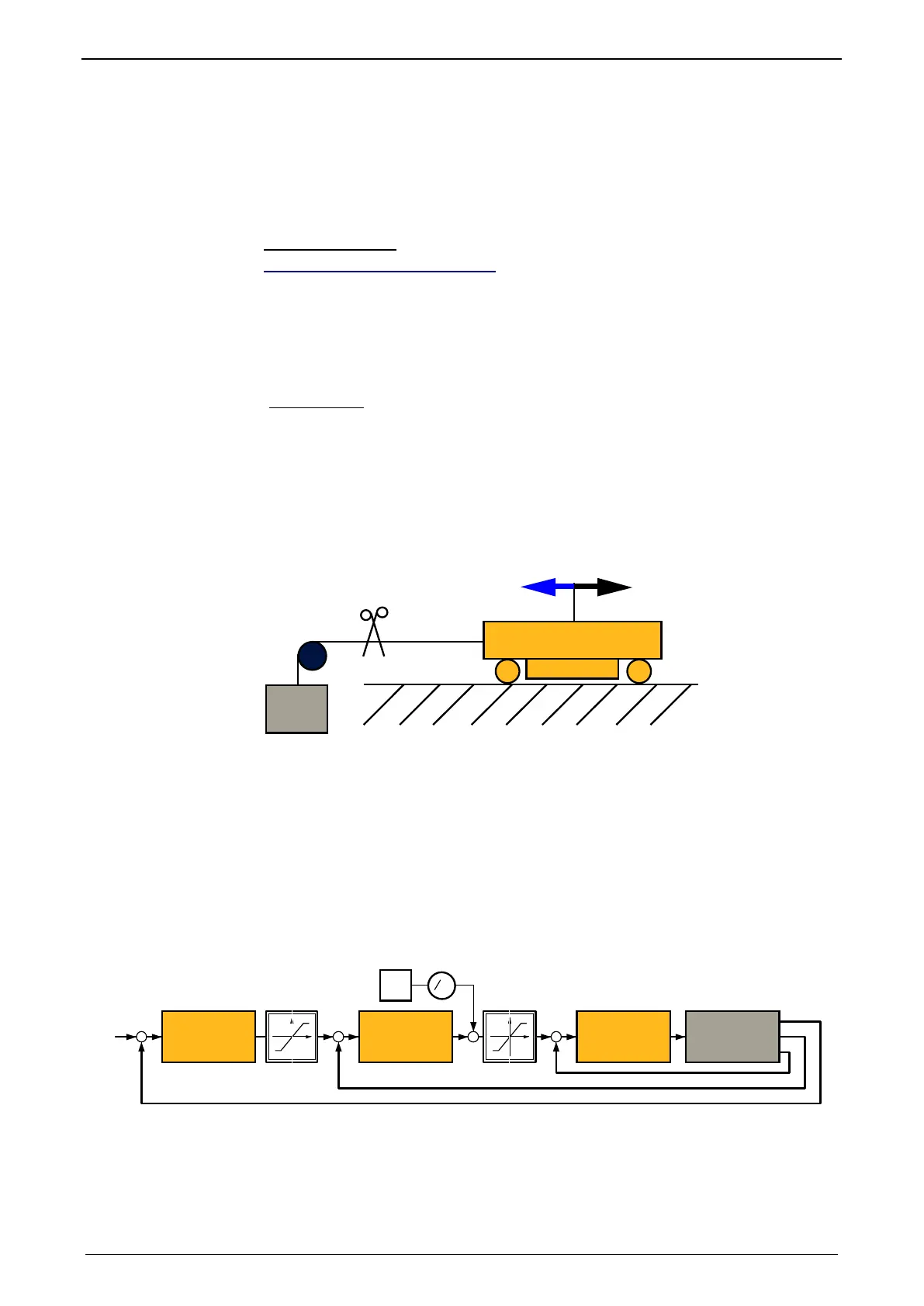

In order to simulate this load jerk electronically, a disturbance current jerk is fed to

the Compax3 as a variable proportional to the disturbance torque at the velocity

controller output.

Electronic simulation of a disturbance torque jerk with the disturbance

current jerk

Current Controller

Stromregelung

Motor

Speed Controller

Drehzahlregelung

Position Controller

Positionsregler

Xw

X n i

1

K

T

1

1:

Feeding in of a disturbance current jerk, which corresponds to a disturbance torque jerk.

The maximum amplitude an the settling time of the following error decline with

rising dynamic stiffness. The settling behavior of the following error is furthermore a

measure for the attenuation and the bandwidth of the control.

Loading...

Loading...