Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

Cascade control

In this chapter you can read about:

Structure of a cascade control ....................................................................................... 200

Cascade structure of Compax3...................................................................................... 200

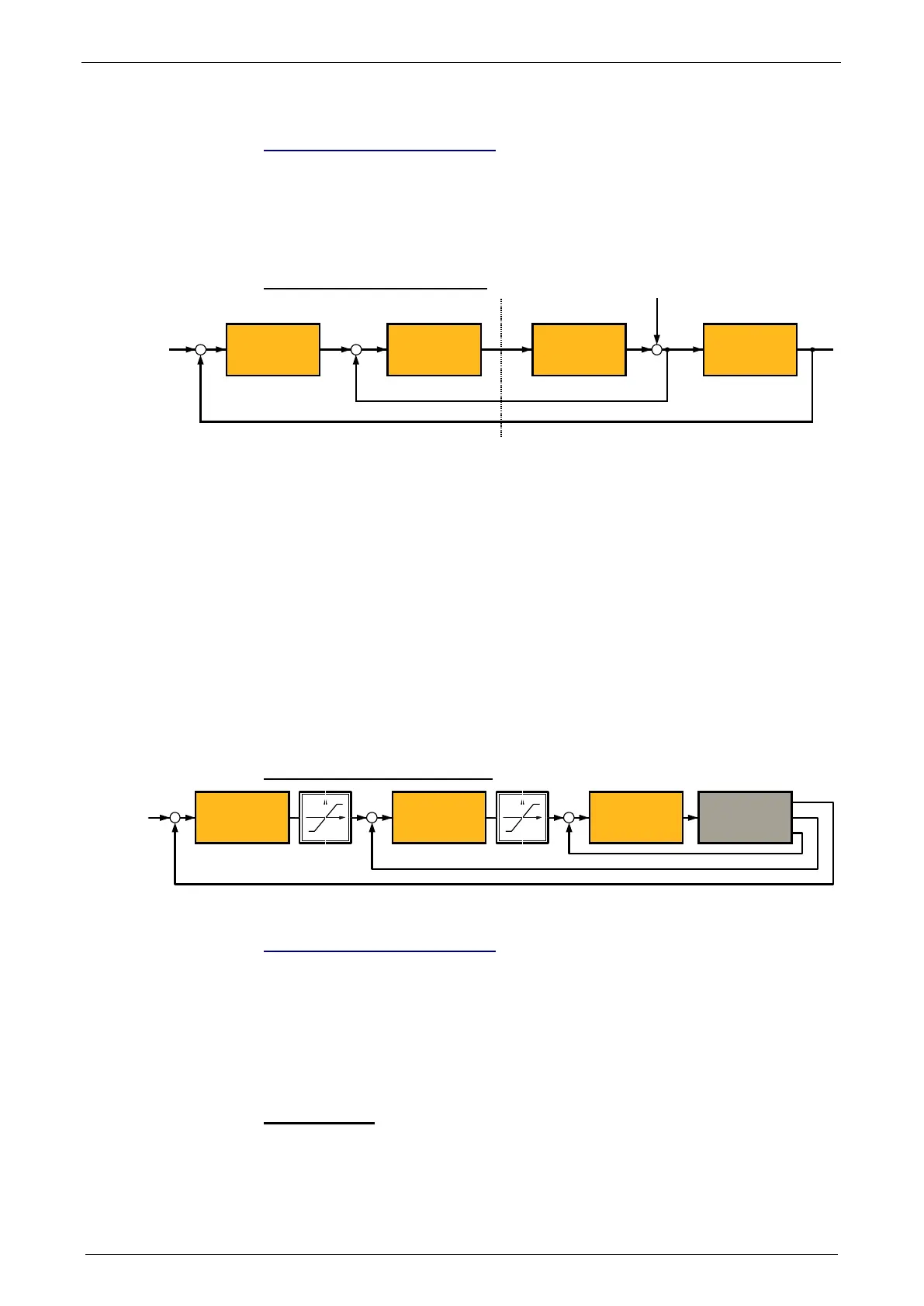

In drive technology, a cascading structure with several controllers (normally 3) is

often used. This improves the control behavior. For this, additional sensors must be

fixed within the control path. You will get the structure of a cascade control.

Structure of a cascade control

Z

Process / Prozess

X2X1W1W2

Controller1

Regler 1

Controller 2

Regler 2

Process Part 1

Streckenteil 1

Process Part 2

Steckenteil 2

W1 Setpoint value (setpoint) for the superposed controller 2

W2 Setpoint value (setpoint) for the subordinate controller 1

X2: Actual variable (actual value) for controller 2

X1: Actual variable (actual value) for controller 1

The cascade control offers the following advantages:

Disturbances occurring within the control path, can be compensated in the

subordinate control loop. Therefore they must not pass through the entire control

path and are thus compensated earlier.

The delay times within the path can be reduced for the superposed controller.

The limitation of the intermediate variables can be made by the control variable

limitation of the superposed controller rather easily .

The effects of the non-linearity for the superposed controllers can be reduced by

the subordinate control loops.

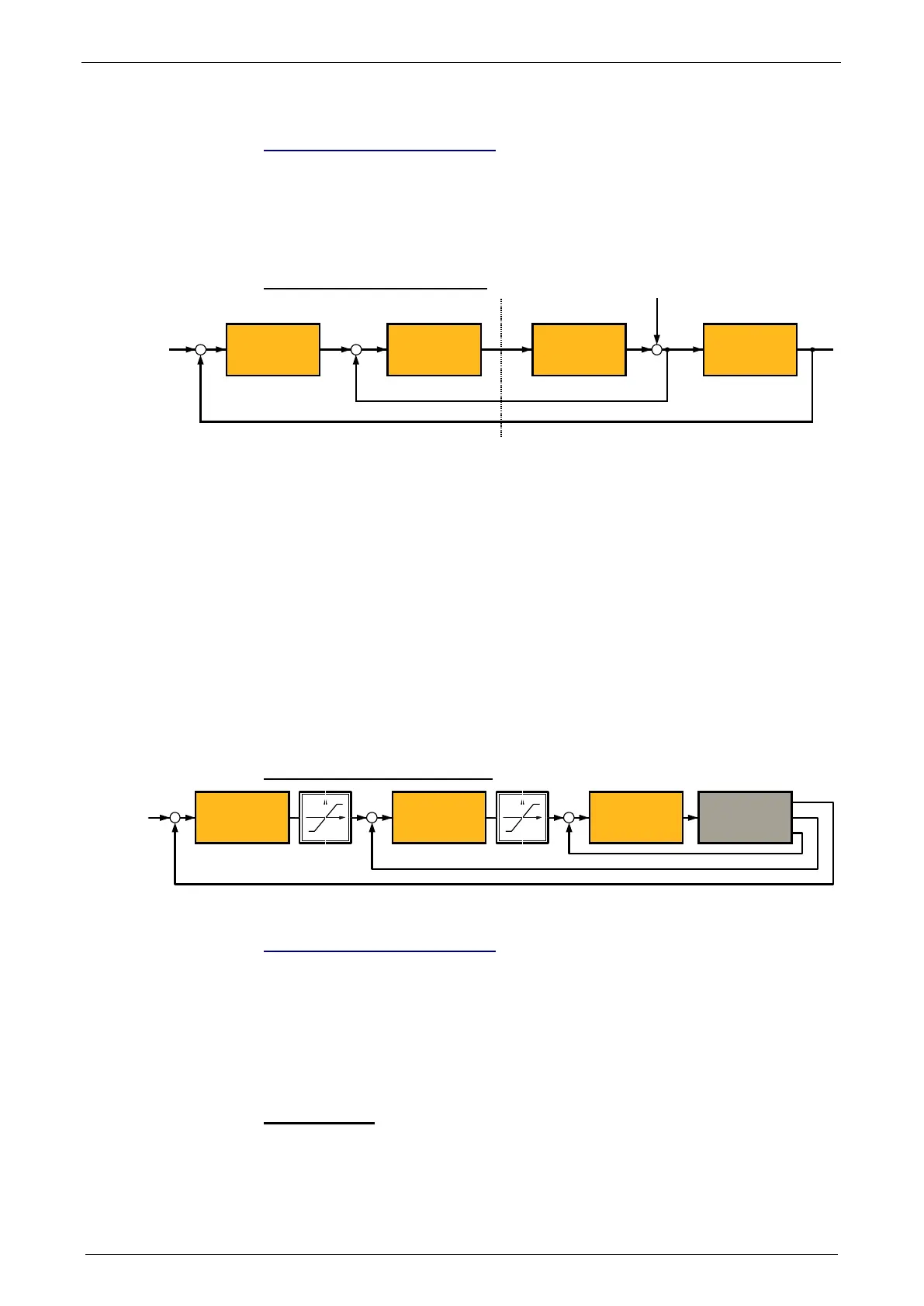

In the Compax3 servo drive, a triple cascade control is implemented with the

following controllers - position controller, velocity controller and current controller.

Cascade structure of Compax3

Current Controller

Stromregelung

Motor

Speed Controller

Drehzahlregelung

Position Controller

Positionsregler

Xw

X n i

Rigidity

In this chapter you can read about:

Static stiffness ............................................................................................................... 200

Dynamic stiffness .......................................................................................................... 201

Correlation between the terms introduced...................................................................... 202

The stiffness of a drive represents an important characteristic. The faster the

disturbance variable can be compensated in the velocity control path and the

smaller the oscillation caused, the higher the stiffness of the drive. With regard to

stiffness, we distinguish static and dynamic stiffness.

Static stiffness

The static stiffness of a direct drive is comparable with the spring rate D of a

mechanical spring, and indicates the excursion of the spring in the event of a

constant interference force. It is the ratio between the constant force FDmax of the

motor and a position difference. Due to the I term in the velocity controller, the

static stiffness is therefore infinitely high in theory, as the I term is integrated until

Loading...

Loading...