Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

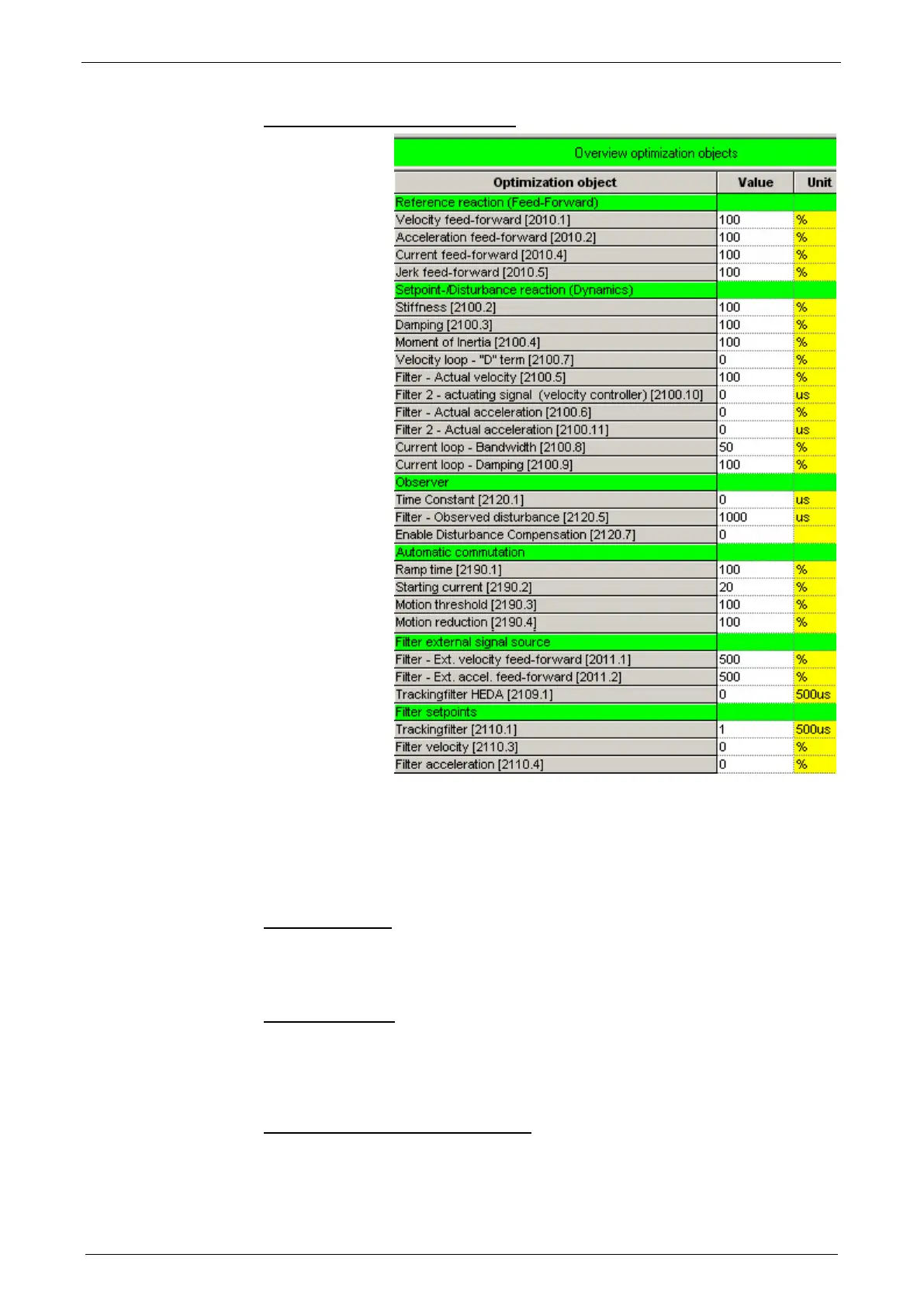

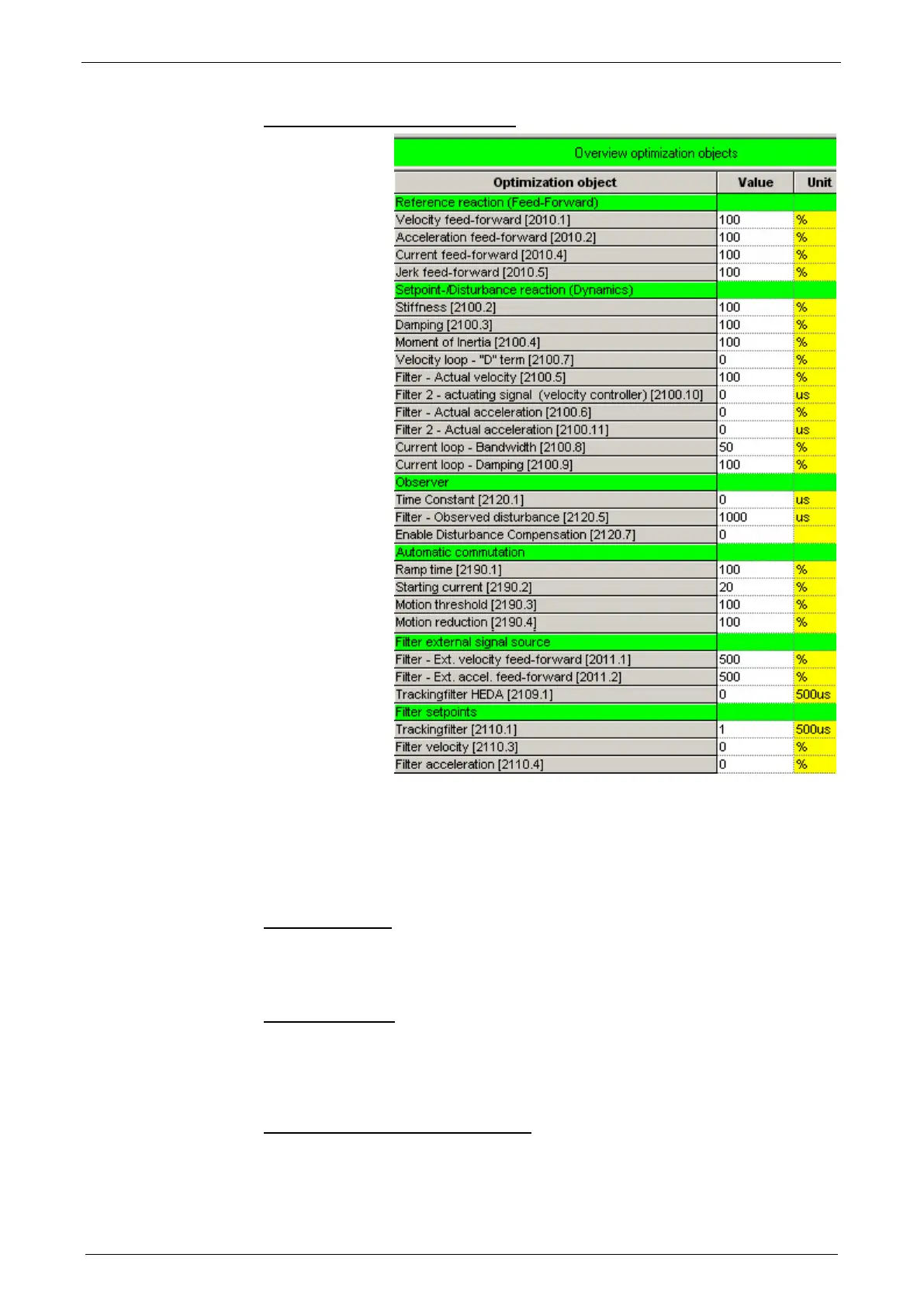

Optimization parameter Advanced

Current controller

The current controller works with a P component in the feedback; this results in

very low overshoot.

With the aid of object 2220.27 (Bit = “0”), it is possible to switch to P component in

the forward path.

EMC feedforward

The EMC feedforward compensates the electromagnetically generated back e.m.f.

of the motor U

EMC

. This signal is proportional to velocity and is deduced from the

setpoint velocity of the setpoint generator.

Motor parameters

Furthermore you can re-optimize the motor parameters inductance, resistance and

EMC (or Kt) in the advanced mode. The LdLqRatio parameter is the ratio of the

smallest and the highest inductance value of the winding, measured during one

motor revolution.

Filter "External Command Interface"

Signal filtering with external command value (see on page 238, see on page

238, see on page 239)

Loading...

Loading...