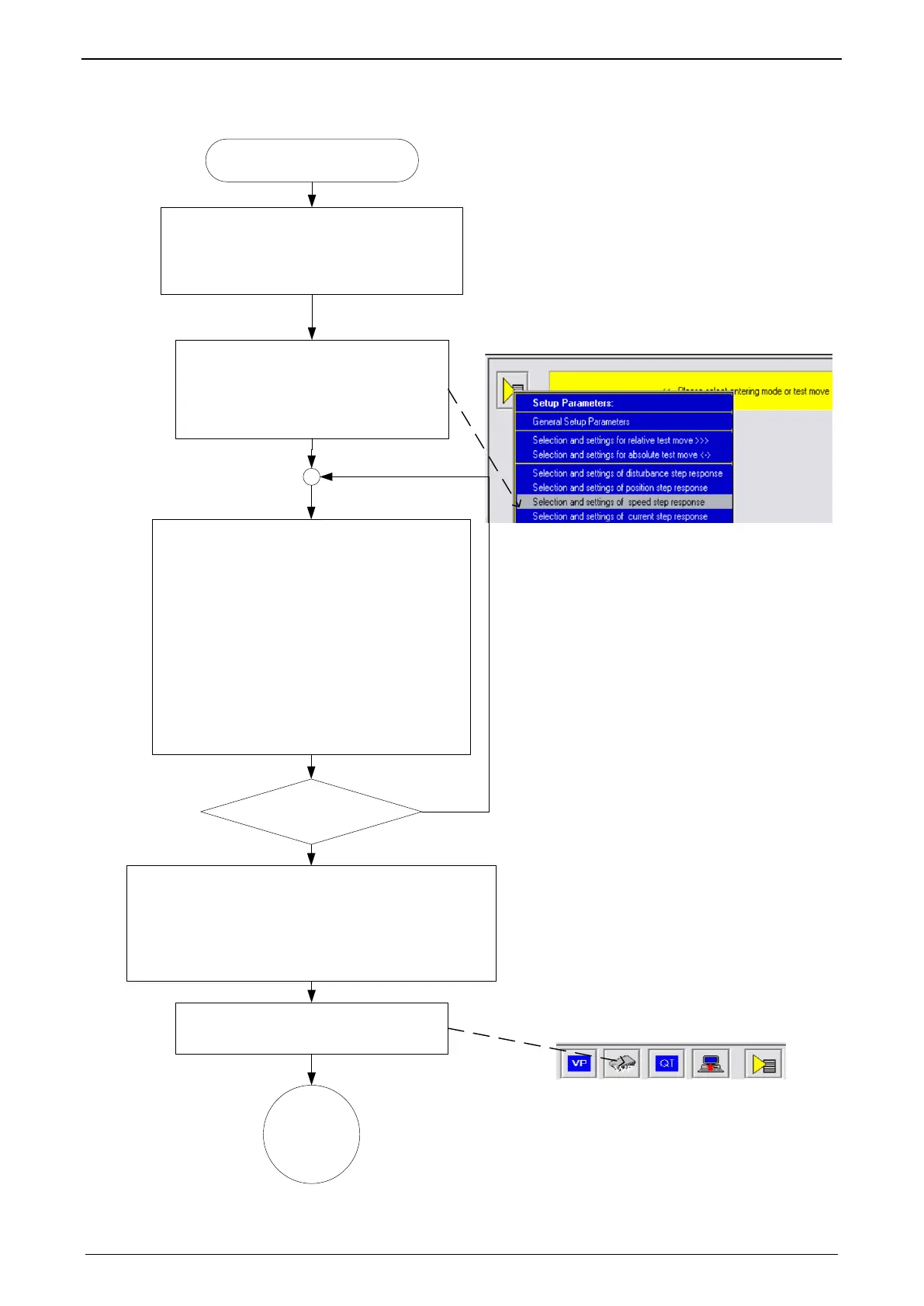

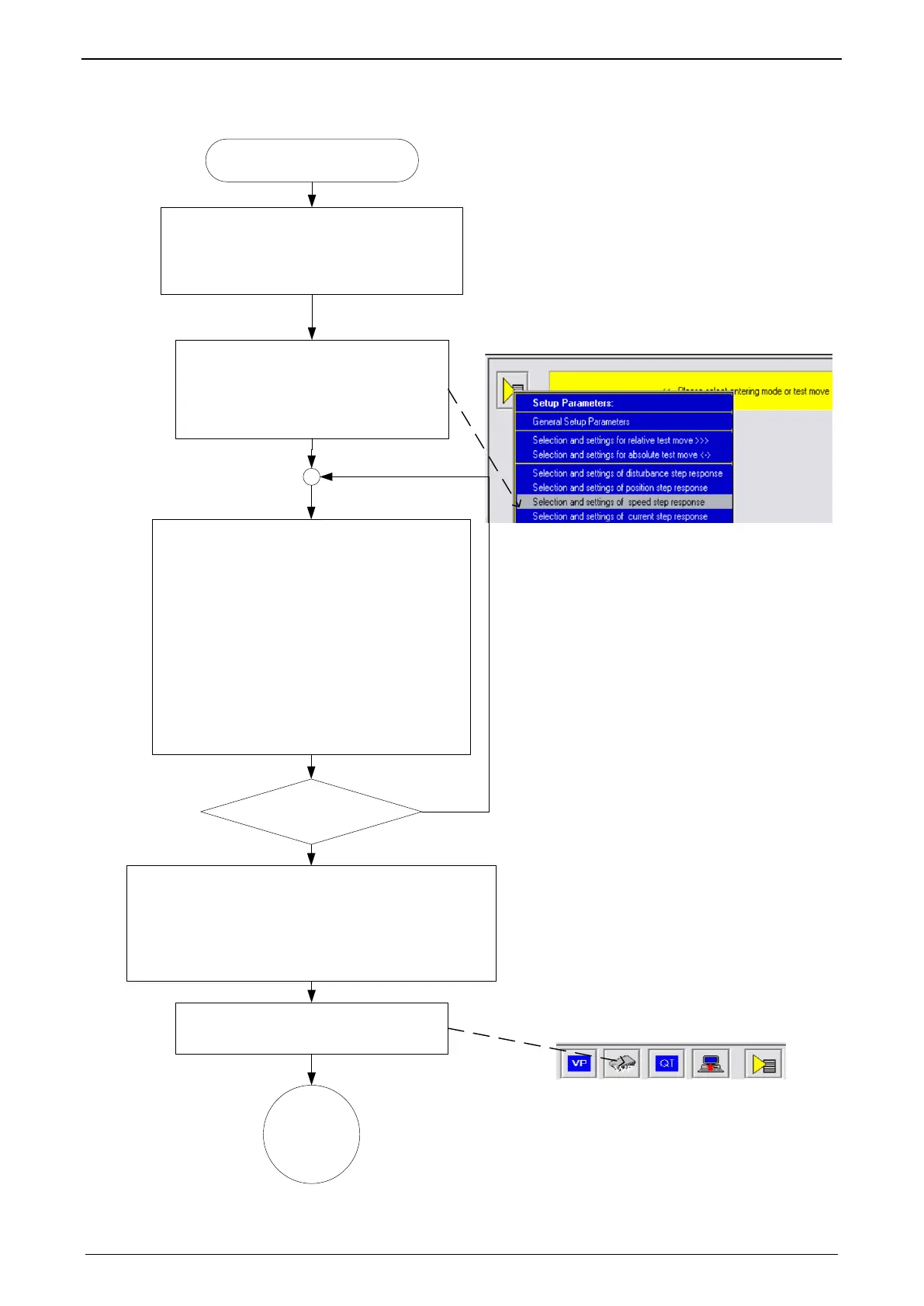

„Controller optimization Advanced“

Observer technology

Observer time constant (Obj. 2120.1) >=125µs

(the higher the value, the slower the observer)

Select speed jerk response in the setup window /

tab “parameter”, select the size of the jerk and

specify the jerk.

Respect the setpoint speed and the actual speed

Smooth, stable behavior?

yes

no

Main diagram

Move over the entire positioning range, verify the

settings and correct if necessary.

Store settings with WF!

Stabilize controller with the aid of:

• Decrease stiffness (Obj. 2100.2)

• or/also reduce observer time constant (Obj. 2120.1)

• or/also reduce control signal filter (Obj. 2120.1)

• or/also modify attenuation (Obj. 2100.3)

• Vary filter of observed disturbance (Obj. 2120.5) or switch off

disburbance (reduce stiffness before!)

1.) Vary “observer time constant” (Obj. 2120.1)

increase “stiffness” (Obj. 2100.2) until the optimum is

reached

2.) In systems with high friction, reduce “attenuation”

(Obj. 2100.3) and increase “stiffness” (Obj. 2100.2)

until the optimum is reached.

3.) In the event of optimization to speed constancy,

increase “attenuation” (Obj. 2100.3) and reduce

“stiffness” as far as necessary (Obj. 2100.2) until the

optimum is reached.

4.) Disturbance (Obj. 2120.7) in connection with the

“filter of observed disturbance” (Obj. 2120.5)

may cause further improvements.

Loading...

Loading...