206 Rockwell Automation Publication 450L-UM001D-EN-P - December 2019

Appendix B Typical Installations

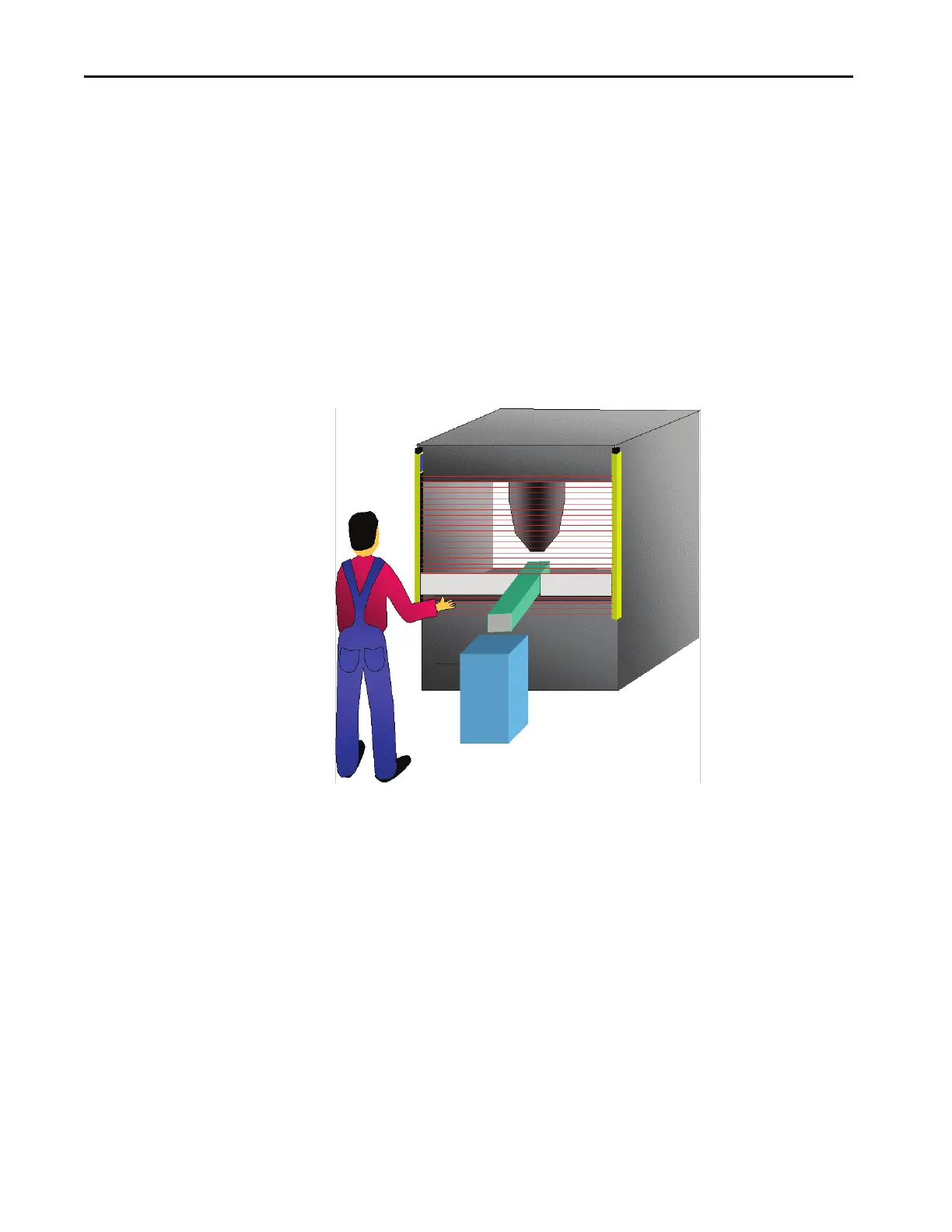

Fixed Blanking Application

This application can include a sheet of metal that passes through the light curtain

before an operation is performed to form the material. The light curtain permits

the material at a specific width without causing the safety outputs to turn off.

Certain applications cannot be protected in any other way. If, for example,

normal operation of a machine requires that material is permanently fed into the

dangerous part of a machine, then a portion of the protective field is always

interrupted, but the machine nevertheless continues to operate. The protection

with blanking must come from a detailed risk analysis. Authorized personnel

must confirm that in spite of blanking, the safety of the machine operator is

adequately accounted for. When necessary, additional protective measures must

be taken to shield the dangerous area. All Blanking modes can create “holes” in

the protective field. These “holes” must be considered separately in the risk

analysis.

Figure 191 - Schematic Application for Fixed Teach-in Blanking

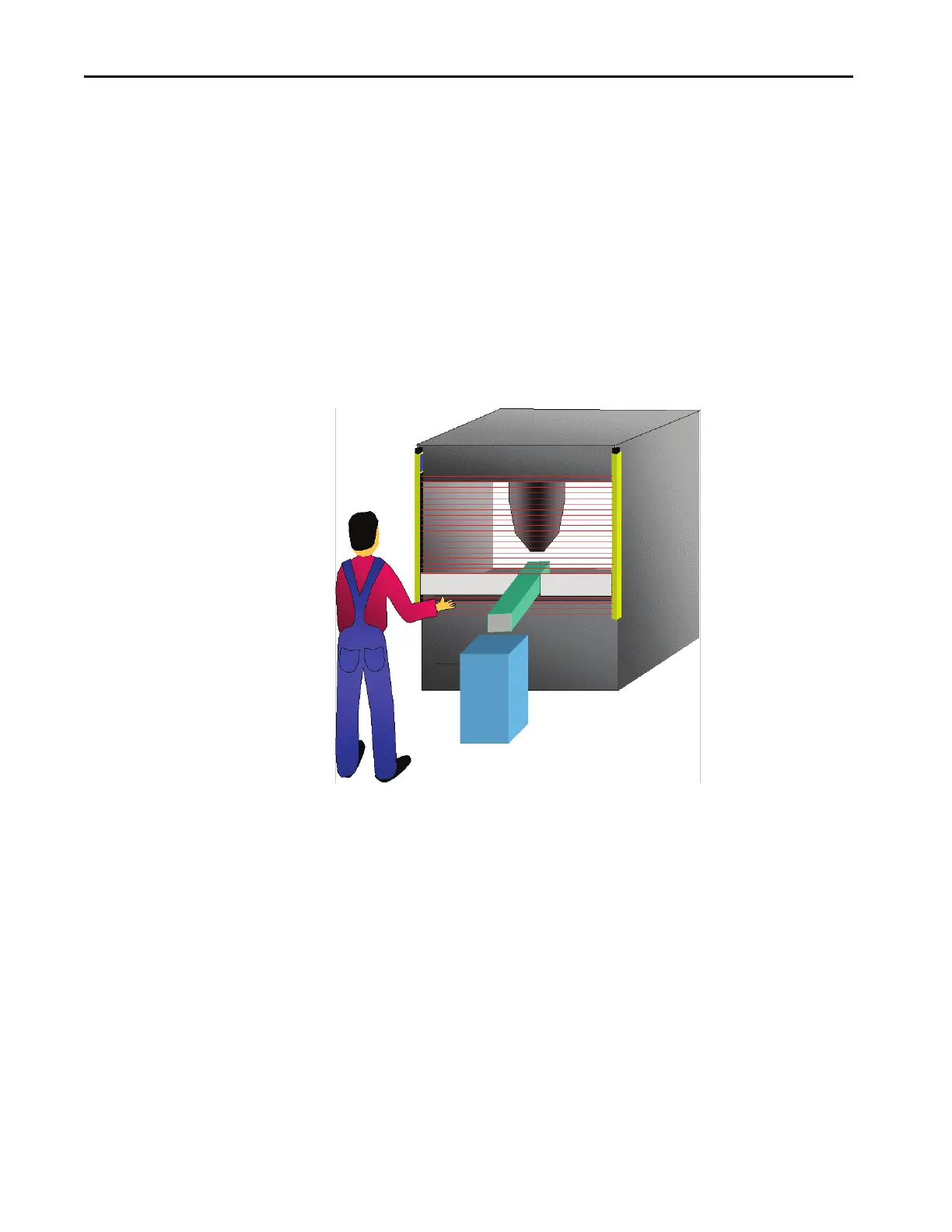

A typical example of fixed Teach-in blanking is also the exit ramp on an

automatic punch press. The punched part is transported out of the dangerous

zone into a container. The ramp passes through the protective field, and without

Blanking would cause the machine to stop. The position of this ramp is

monitored. During a tool change, the position of this ramp may vary slightly.

This new position must be reconfigured in order for the application to run

smoothly. It is possible this new position needs reconfiguration in order for the

application to run smoothly.

Loading...

Loading...