82 Rockwell Automation Publication 450L-UM001D-EN-P - December 2019

Chapter 6 Installation and Wiring

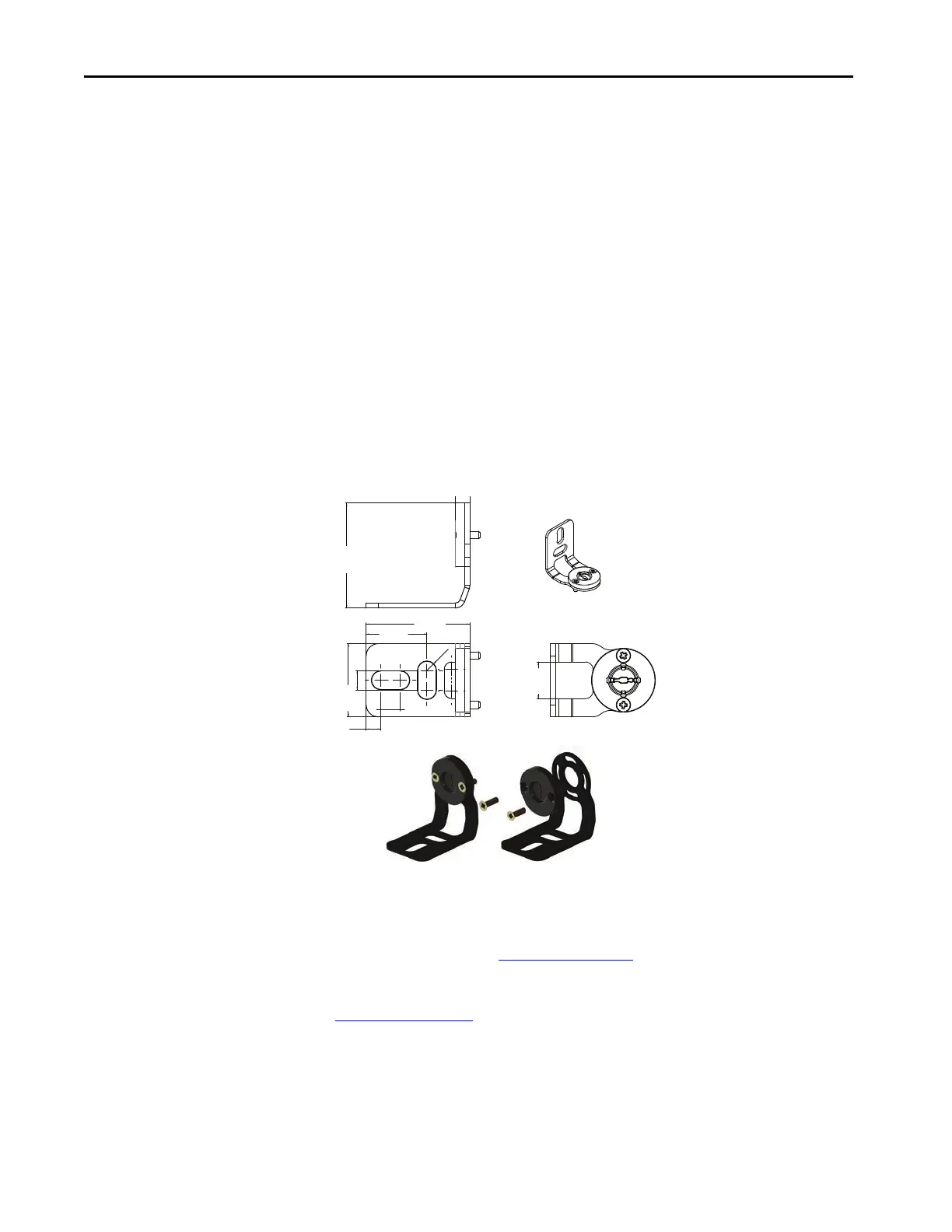

Mounting Brackets

Standard Top/Bottom Mounting Kit

The GuardShield safety light curtain can be mounted using right angle brackets

that are attached to the end caps of both the transmitter and receiver sticks. A

pair of end cap mounting brackets are supplied with each stick.

The required screwdriver type for installation of the standard top/bottom

mounting kit is a Phillips screwdriver for M3 x 10 Phillips DIN 965 A screw. The

maximum torque cannot be above 0.7 N•m (6.19 lb•in) otherwise the light

curtain could become damaged.

The top/bottom mounting kit allows a rotation of ±20% of the GuardShield

safety light curtain aluminum profile.

The length of the transceiver stick and the vibration and shock conditions of the

application often require use of additional side mounting brackets.

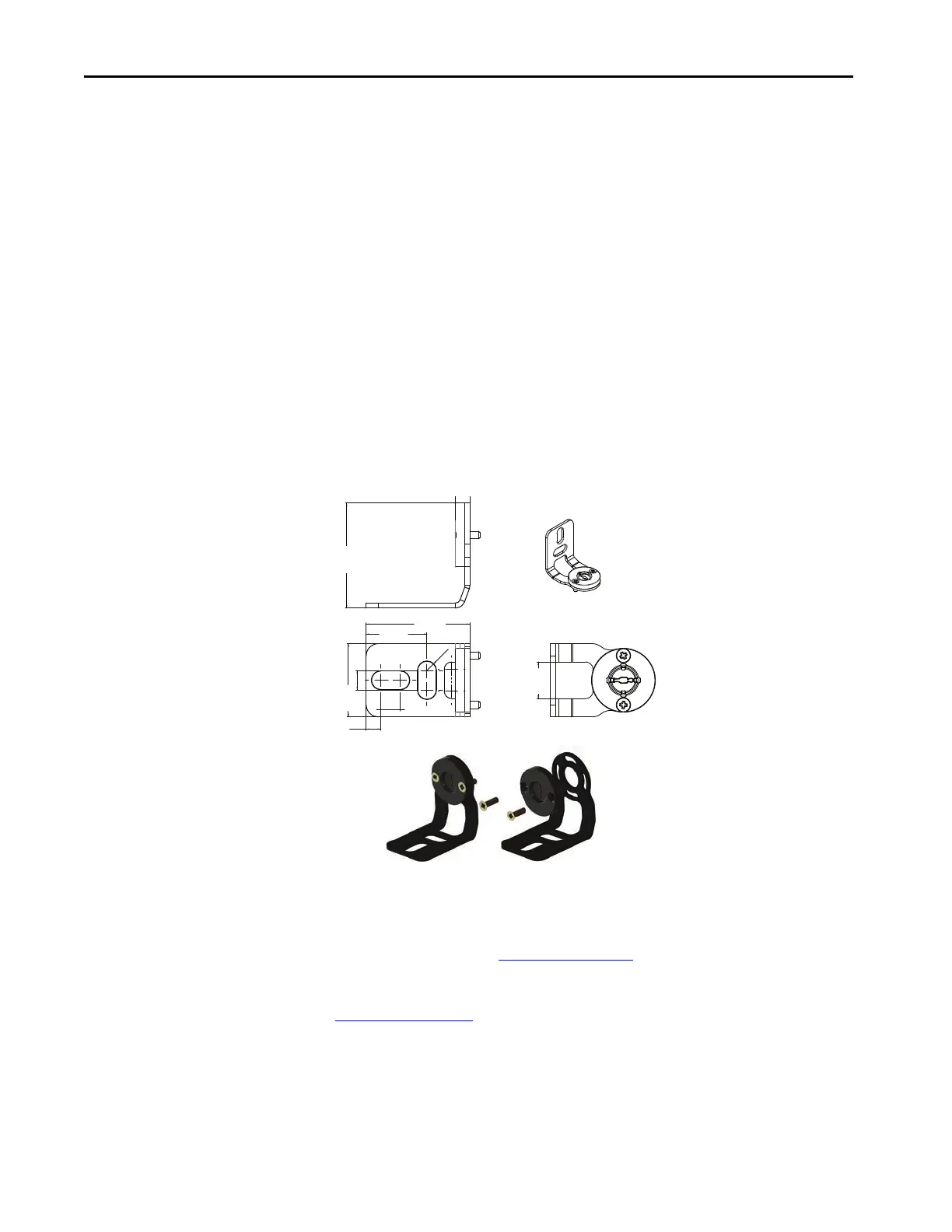

Figure 49 - Standard Mounting Bracket Kit, Which Is Supplied with Each Stick (Catalog Number

450L-AM-TBM: Contains Two Brackets for One Stick)

Two M6 DIN 912 screws (not provided) are required for proper mounting of

each stick.

Photos that are shown in Figure 50 on page 83

present different cable guide

options. The bend radius of the plug-in pig tail cable is small enough so that the

cable can be routed at a 90° angle. The minimum bend radius is specified in

Table 77 on page 192

.

43

(1.69)

8 (0.35)

42.5 (1.67)

30

(1.18)

R4 (0.16)

6

(0.24)

24.9 (0.98)

8

(0.35)

15

(0.59)

Loading...

Loading...