Supplemental Drive Information A-3

PowerFlex® 700L Liquid-Cooled Drive User Manual

Publication 20L-UM001D-EN-P

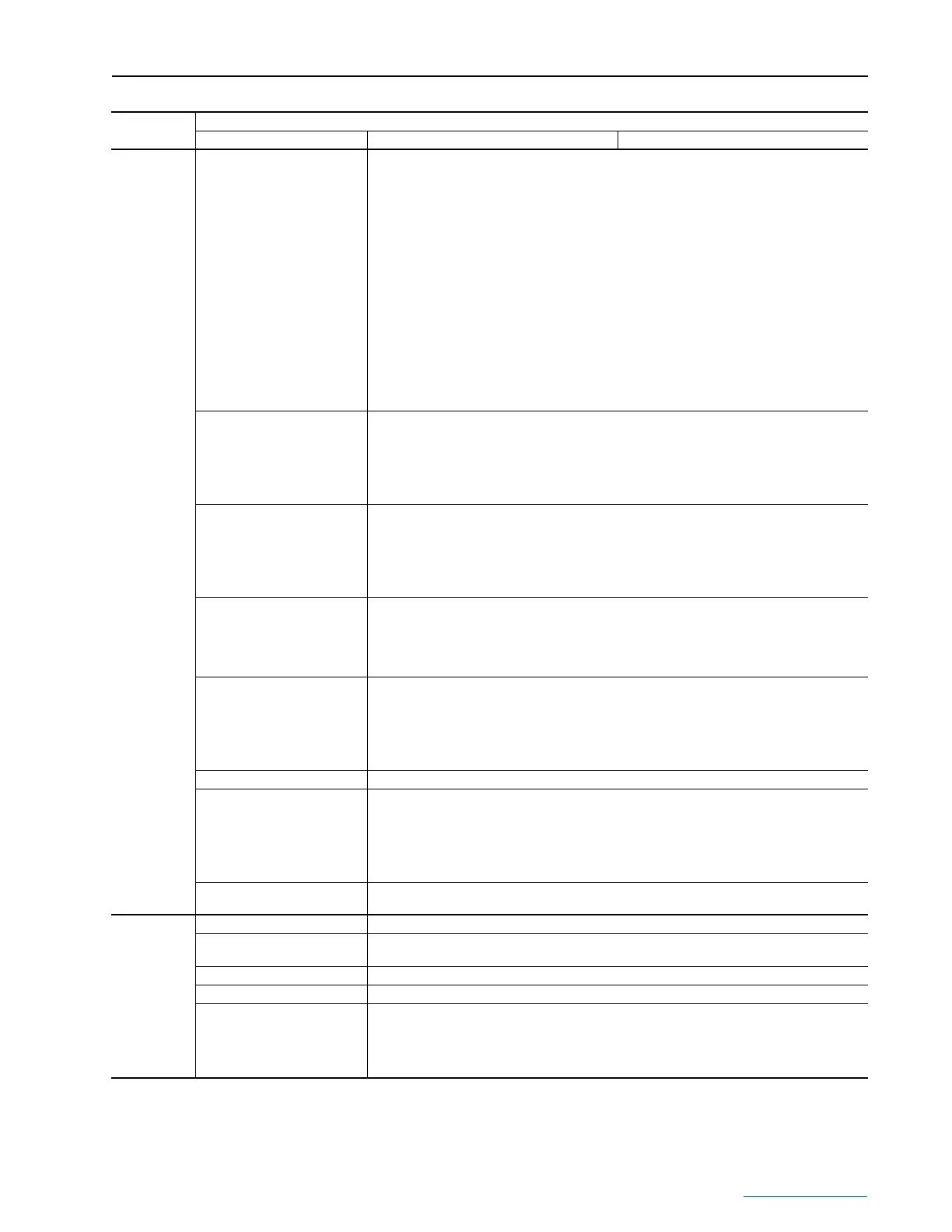

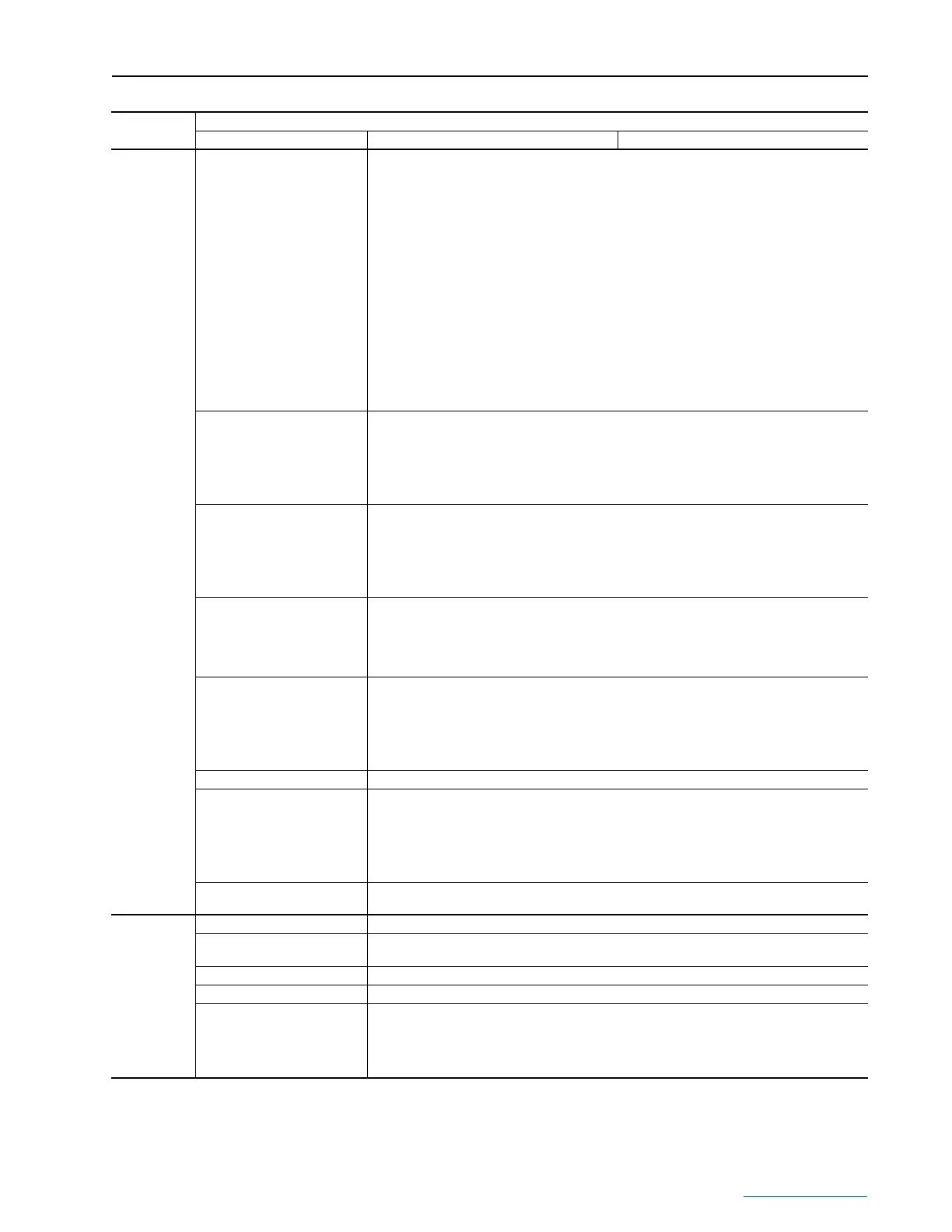

Control

(continued)

Speed Control

Vector Control: Speed Regulation - without feedback (Vector Control Mode)

0.1% of base speed across 120:1 speed range

120:1 operating range

50 rad/sec bandwidth

Speed Regulation - with feedback (Vector Control Mode)

0.001% of base speed across 120:1 speed range

1000:1 operating range

250 rad/sec bandwidth

700S Phase II Control: Speed Regulation - without feedback

0.1% of base speed across 120:1 speed range

120:1 operating range

50 rad/sec bandwidth

Speed Regulation - with feedback

0.001% of base speed across 120:1 speed range

1000:1 operating range

740 rad/sec bandwidth

Torque Regulation

Vector Control: Torque regulation without Feedback; ± 5%, 600 rad/sec bandwidth

Torque regulation with Feedback; ± 2%, 2500 rad/sec bandwidth

700S Phase II Control: Torque regulation without Feedback; ± 10%, 600 rad/sec bandwidth

Torque regulation with Feedback; ± 5%, 4400 rad/sec bandwidth

Selectable Motor Control

Vector Control: Sensorless Vector with full tuning. Standard V/Hz with full custom capability and Vector Control

with Force Technology (with and without feedback).

700S Phase II Control: Vector Control with Force Technology (with and without feedback), V/Hz Control, and permanent

magnet motor control.

Stop Modes

Vector Control: Multiple programmable stop modes including Ramp, Coast, DC-Brake, Ramp-to-Hold, and

S-curve.

700S Ph. II Control: Multiple programmable stop modes including Ramp, Coast, and Current Limit.

Accel/Decel

Vector Control: Two independently programmable accel and decel times. Each time may be programmed from

0-3600 seconds in 0.1 second increments.

700S Phase II Control: Independently programmable accel and decel times, adjustable from 0-6553.5 seconds in 0.01

second increments.

Intermittent Overload: 110% Overload capability for up to 1 minute 150% Overload capability for up to 3 seconds

Current Limit Capability

Vector Control: Proactive Current Limit programmable from 20 to 160% of rated output current. Independently

programmable proportional and integral gain.

700S Phase II Control: Independent Motoring and Regenerative Power Limits programmable to 800% of rated output

current.

Electronic Motor Overload

Protection:

Class 10 protection with speed sensitive response. Investigated by U.L. to comply with N.E.C.

Article 430. U.L. File E59272, volume 12.

Encoder

(Vector Control

only)

Type: Incremental, dual channel

Supply: 12V or 5V, 250 mA. 12V or 5V, 10 mA minimum inputs isolated with differential transmitter, 250

kHz maximum.

Quadrature: 90°, ± 27° at 25°C

Duty Cycle: 50%, ± 10%

Requirements: Encoders must be line driver type, quadrature (dual channel) or pulse (single channel), 8-15V DC

output (3.5-6V DC for 5V encoder), single-ended or differential, and capable of supplying a

minimum of 10 mA per channel. Maximum input frequency is 250 kHz. The Encoder Interface

Board accepts 12V DC or 5V DC square-wave with a minimum high state of 7.0V DC (12 volt

encoder) or 3.1V DC (5 volt encoder). Maximum low state voltage is 0.4V DC.

Category

Specification

Frame 2 Frames 3A and 3B

Loading...

Loading...