3-10

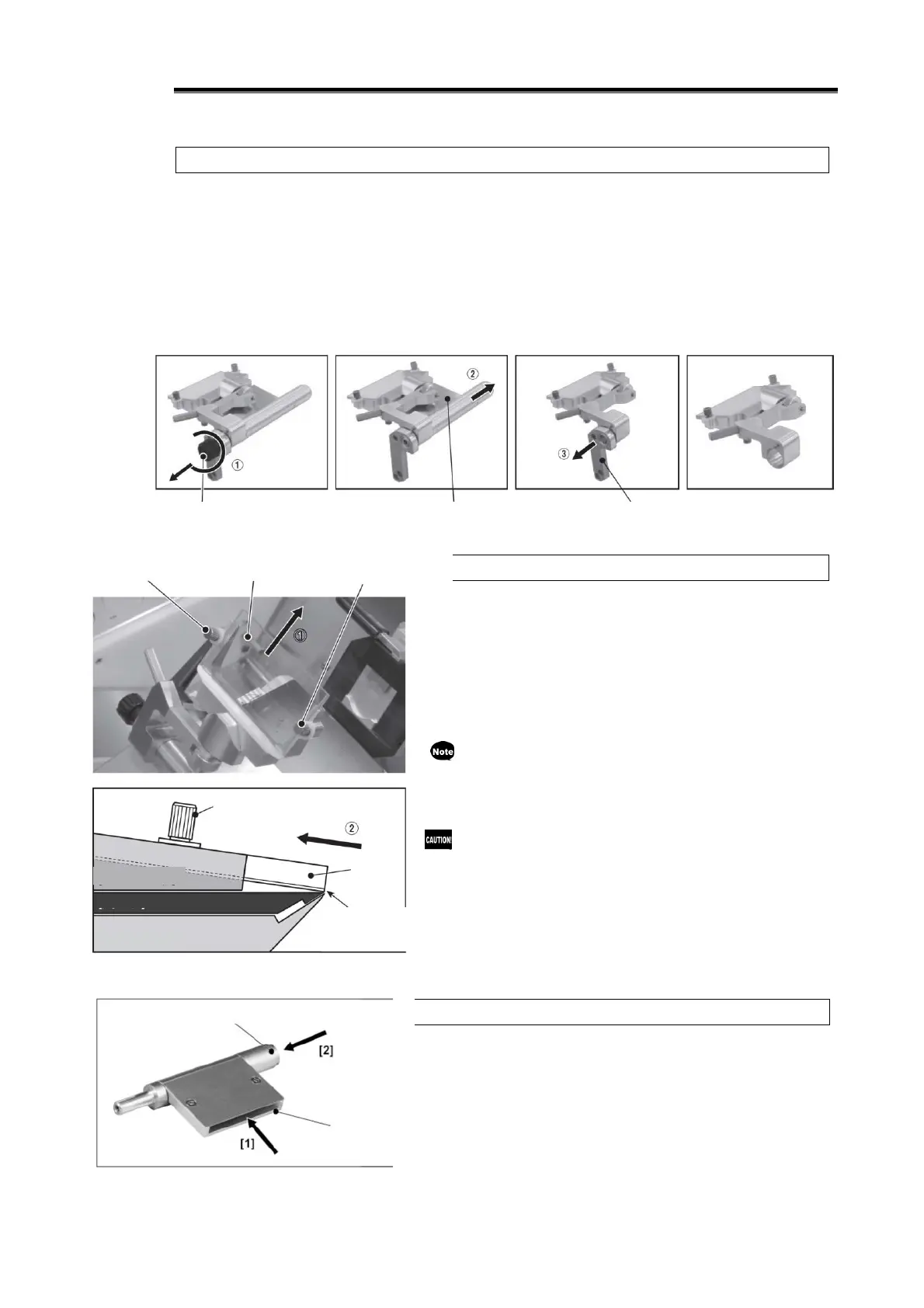

Disassembling and Assembling the Anti-Roll Plate

The removed Anti-Roll Plate can be disassembled for easy care.

1. Turn the black knurled screw and pull it out [1].

2. Remove the vacuum suction port [2].

3. When the left mounting plate is removed [3], the disassembly is complete.

4. Wipe the disassembled parts with a dry cloth, etc.

If debris collects in the vacuum suction port, etc., use tweezers, drain cleaning brush, etc., to remove the

debris.

5. When the cleaning is complete, follow steps 3 to 1 in this order to restore the original condition.

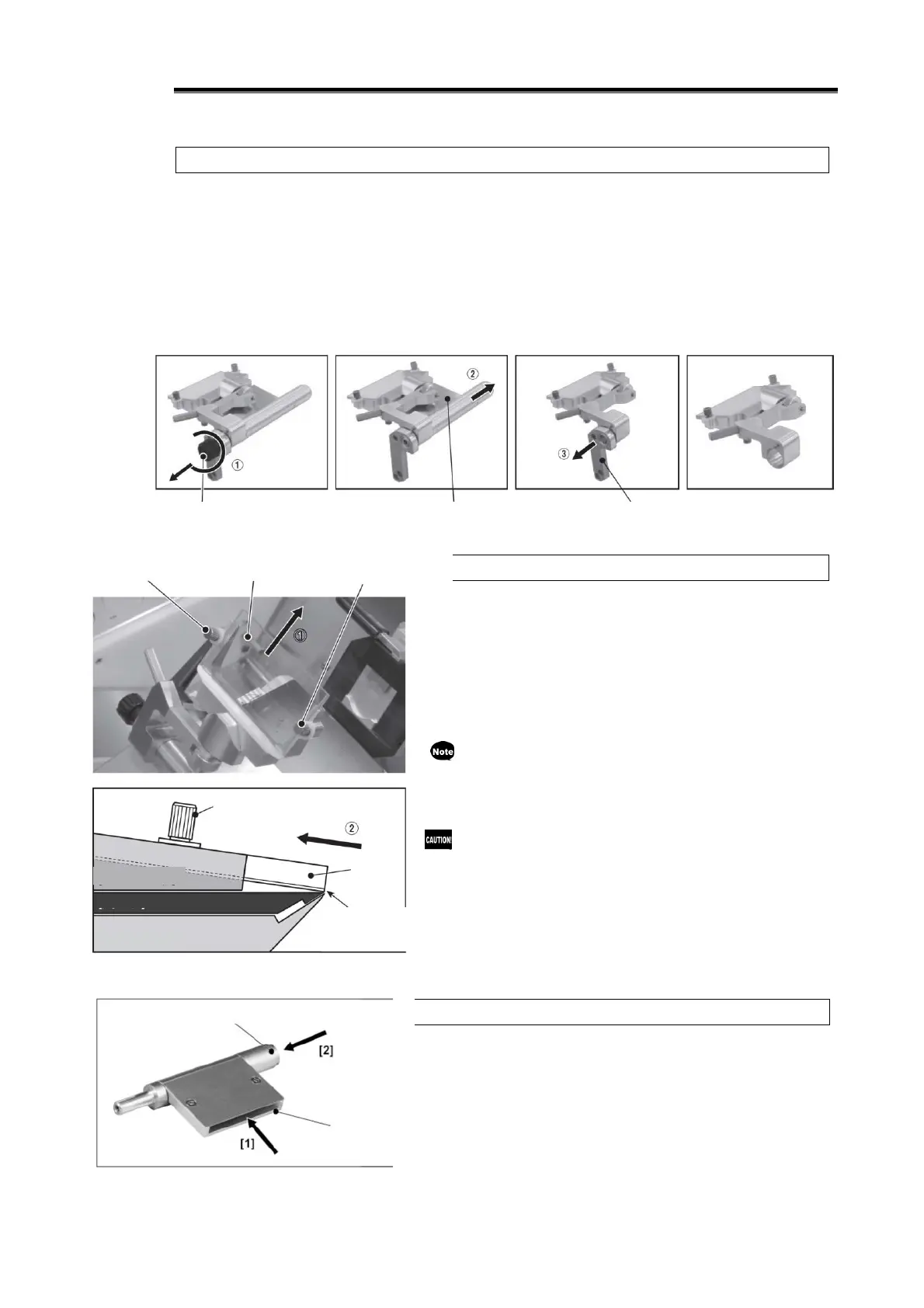

Replacing the Glass of the Anti-Roll Plate

1. Loosen the glass locking screws.

2. Pull out the glass from the Anti-Roll Plate [1].

3. Insert the new glass into the Anti-Roll Plate [2].

Set the glass with clear tapes facing the stage.

When inserting the glass, make sure the bottom of the

trapezoid faces the stage.

4. Tighten the glass locking screws.

Both top and bottom edges of the glass plate of the Anti-Roll

Plate can be used. It is recommended to turn the glass plate

upside down after one edge has been used for about three

months.

If the Anti-Roll Plate falls sharply, its front edge may get

contact with a disposable blade and broken. This may lead to

scatter of glass fragment and cause injury. The broken

Anti-Roll Plate may also interfere with production of good

sections or cause damage to blocks.

Cleaning the Vacuum Suction Port

If debris collects in the vacuum suction port, the vacuum suction

force will drop.

As part of daily care, use tweezers, etc., to remove the collected

debris from the vacuum suction port [1] and vacuum hose

attachment port [2].

Vacuum hose attachment port

-Roll Plate

Clear tape (spacer)

provided under each

side of the glass plate

Loading...

Loading...