4-1

Troubleshooting

Before Suspecting a Trouble ~ Instrument Conditions and Remedial Actions

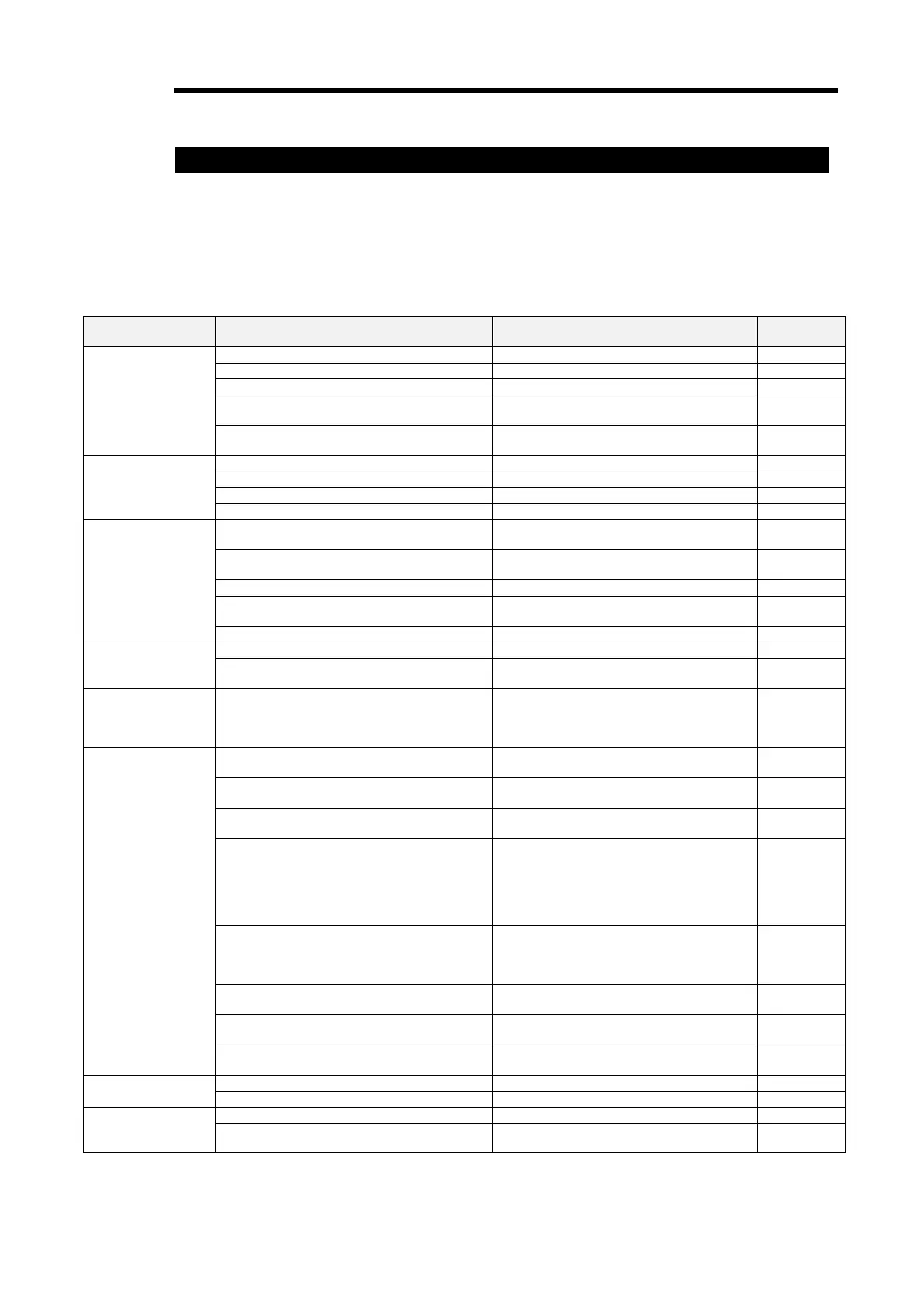

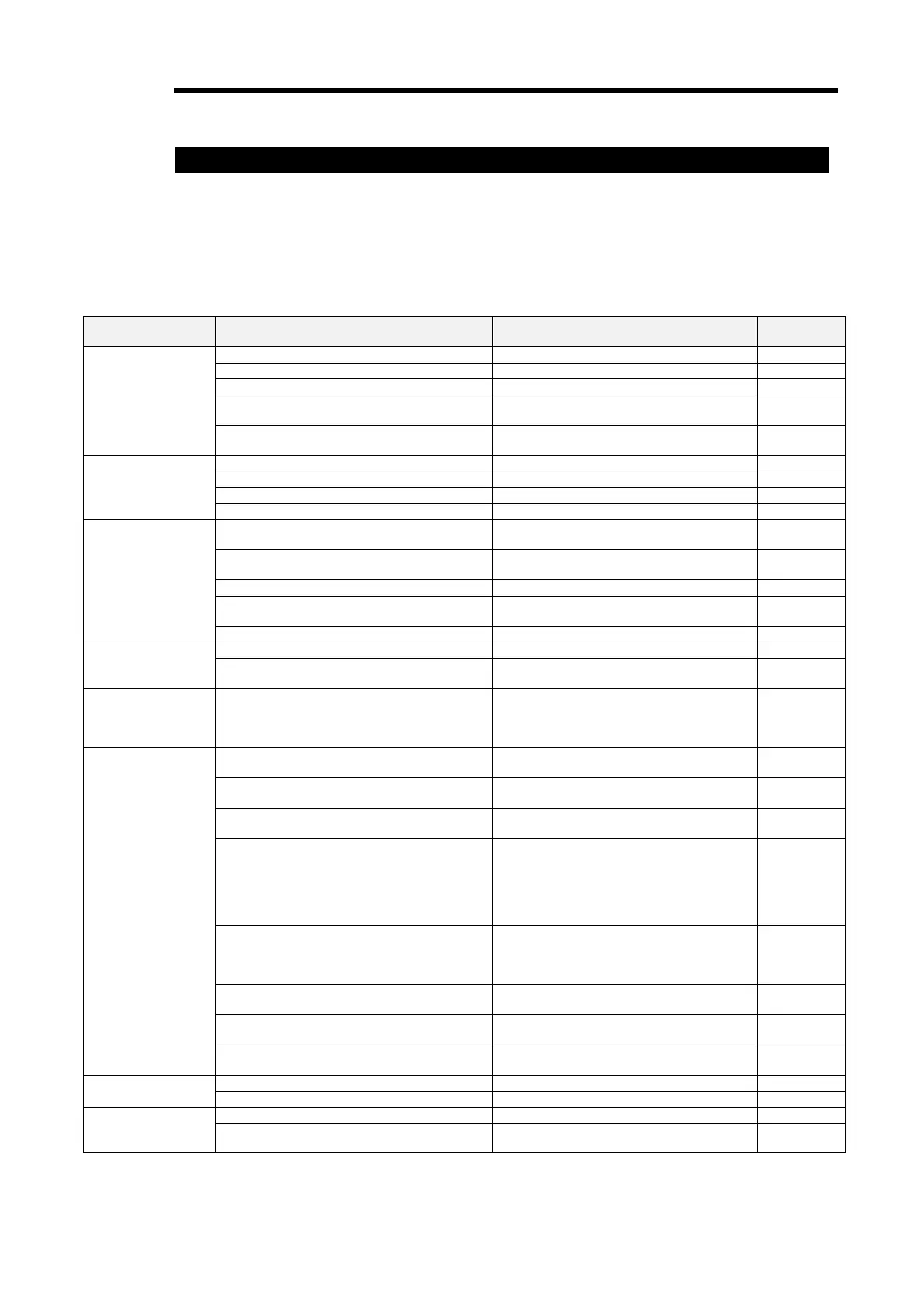

The troubleshooting chart below lists problems that may occur during system operation. Possible causes

and remedial actions are described for each problem. Utilize this information to identify the system

condition and resolve the problem. If the problem cannot be resolved or the applicable condition is not listed,

contact the nearest authorized Sakura distributor or representative.

* If an unexpected problem occurred and the condition cannot be rectified easily, turn off the

power immediately. Contact the nearest authorized Sakura distributor or representative.

Symptom Check Action

on the screen.

Is the power switch turned on?

Isn't the power cable or plug disconnected?

Connect the power cable or plug.

Check the breaker, etc., on the facility side.

The instrument power was temporarily cut off

(momentary power failure).

Turn off the instrument power and then turn it

back on.

Isn't the instrument in the sleep mode or standby

mode?

Touch the screen. The screen should come

back.

does not operate.

Isn't the connector unplugged?

Is the draft generator power turned on?

Is the draft generator setting turned on?

Are the LED lamps on the draft generator lit?

Check the lamp mode table on p. 3-5.

force dropped.

Aren't contaminants trapped in the vacuum

suction port?

Use tweezers, etc., to remove the

contaminants.

Aren't contaminants trapped on the vacuum

filter?

Replace the vacuum filter set.

Aren't contaminants trapped in the hose?

Isn't the connection between the vacuum filter

and hose loose?

Isn't the desired suction force set low?

Raise the set value of desired suction force.

be cooled.

Isn't the setpoint temperature high?

Readjust the setpoint temperature.

Is the operating environment temperature

appropriate?

Check the operating environment

temperature.

sectioning although

the chamber cannot

By using the emergency plastic holder

(optional), heat conduction from the specimen

head can be suppressed to make it difficult for

cut properly.

Aren't contaminants trapped on the blade

holder?

Isn't the blade edge dirty?

Clean the blade edge or change the

disposable blade.

Hasn't the specimen melted due to insufficient

freezing of the block?

Hasn't the sectioning position remained the

same?

The disposable blade has been consumed, so

change the disposable blade. Or, slide the

blade holder to change the position at which

the disposable blade contacts the specimen so

that the entire disposable blade can be used

Are the various levers (specimen head locking

lever, orientation locking lever, disposable blade

mounting lever, blade holder

left/right lever, blade

holder mounting lever) locked?

Are the blade holder coma and wave washer

installed correctly?

Install the blade holder coma and wave

washer correctly.

Are the chamber temperature and specimen

head temperature appropriate?

Adjust the setpoint temperatures.

Are the setpoint temperature and set thickness

appropriate?

Adjust the setpoint temperature and set

thickness.

not move.

Isn't the handwheel lock tab engaged?

Disengage the handwheel lock tab.

Isn't motorized sectioning paused?

Press the stop key to cancel the pause.

(right panel) cannot be

Select the MOTORIZED Tab.

Select the MOTORIZED Tab.

Isn't the handwheel lock tab engaged?

Disengage the handwheel lock tab.

Loading...

Loading...