58 FLOWSIC100 Flare-XT · Operating Instructions · 8023761/V 1-0/2020-10 · © SICK Engineering GmbH

Installation FLSE100-XT

▸

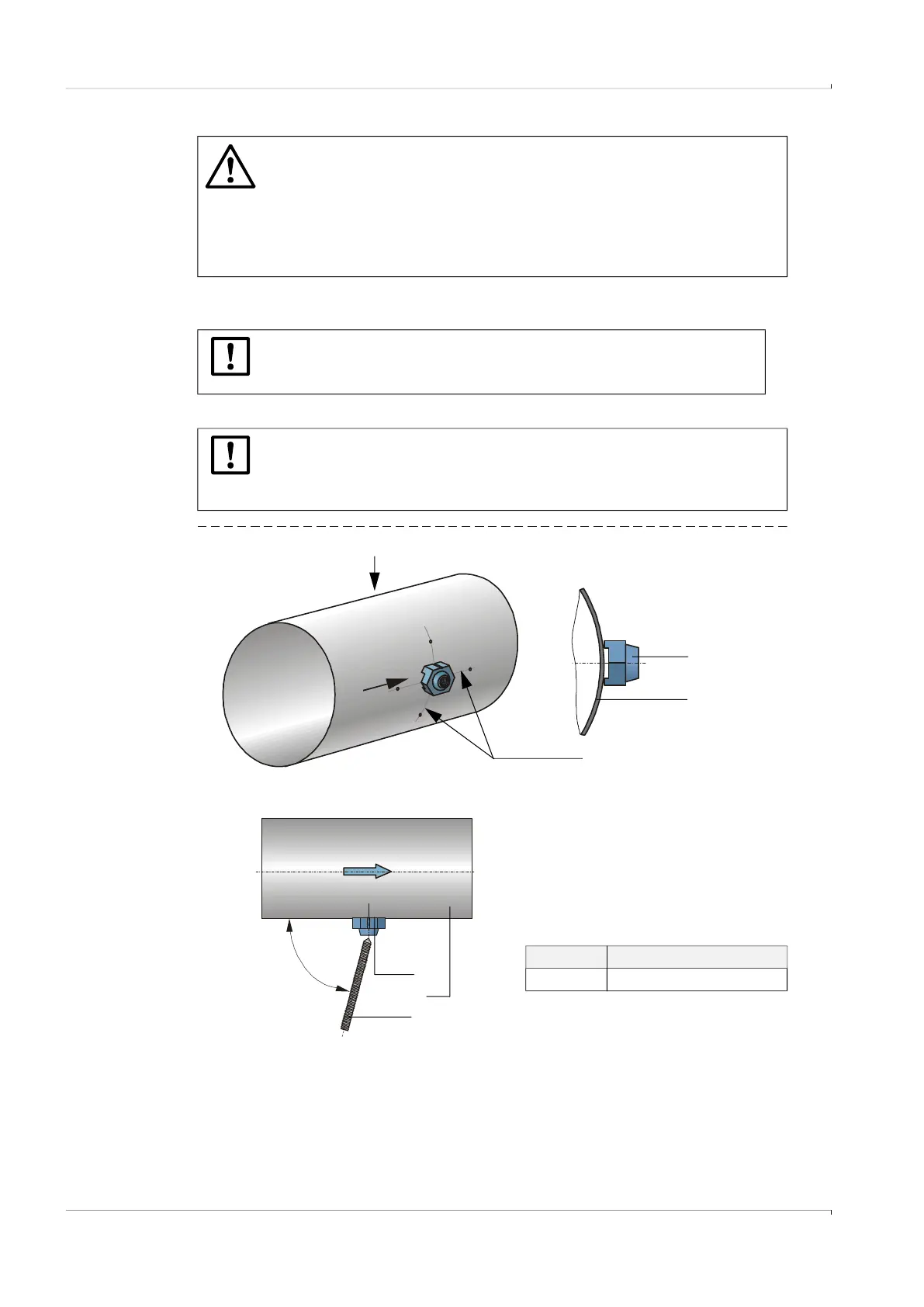

Position the welding aid (1) on the pipeline (2) as shown in → Fig. 27.

▸

Screw in threaded rod (3) with the sharp tip in the welding aid.

Fig. 27 Positioning of the welding aid

▸

Slide centering plate (4) on the cone of the welding aid (1) and fasten with the nut (5).

▸

Slide nozzle (6) over threaded rod and centering plate.

WARNING: Qualified personnel required

● Any welding and installation work on pipelines may only be carried out by

authorized personnel with a specific qualification.

● Special qualified and approved procedures have to be followed. This

procedure requires the written agreement by the plant operator.

● The general safety requirements and all other plant operator instructions

have to be followed.

NOTICE:

Check the welding aid position after welding. The deviation from the drawn

lines must not be more than 0.5 mm. Otherwise reposition the welding aid.

NOTICE:

The threaded rod is fitted by the manufacturer with a clamp ring. This is to aid

removal of the centering plate following installation of the nozzles. The clamp

ring should therefore not be removed.

1

2

View A

A

Marking lines

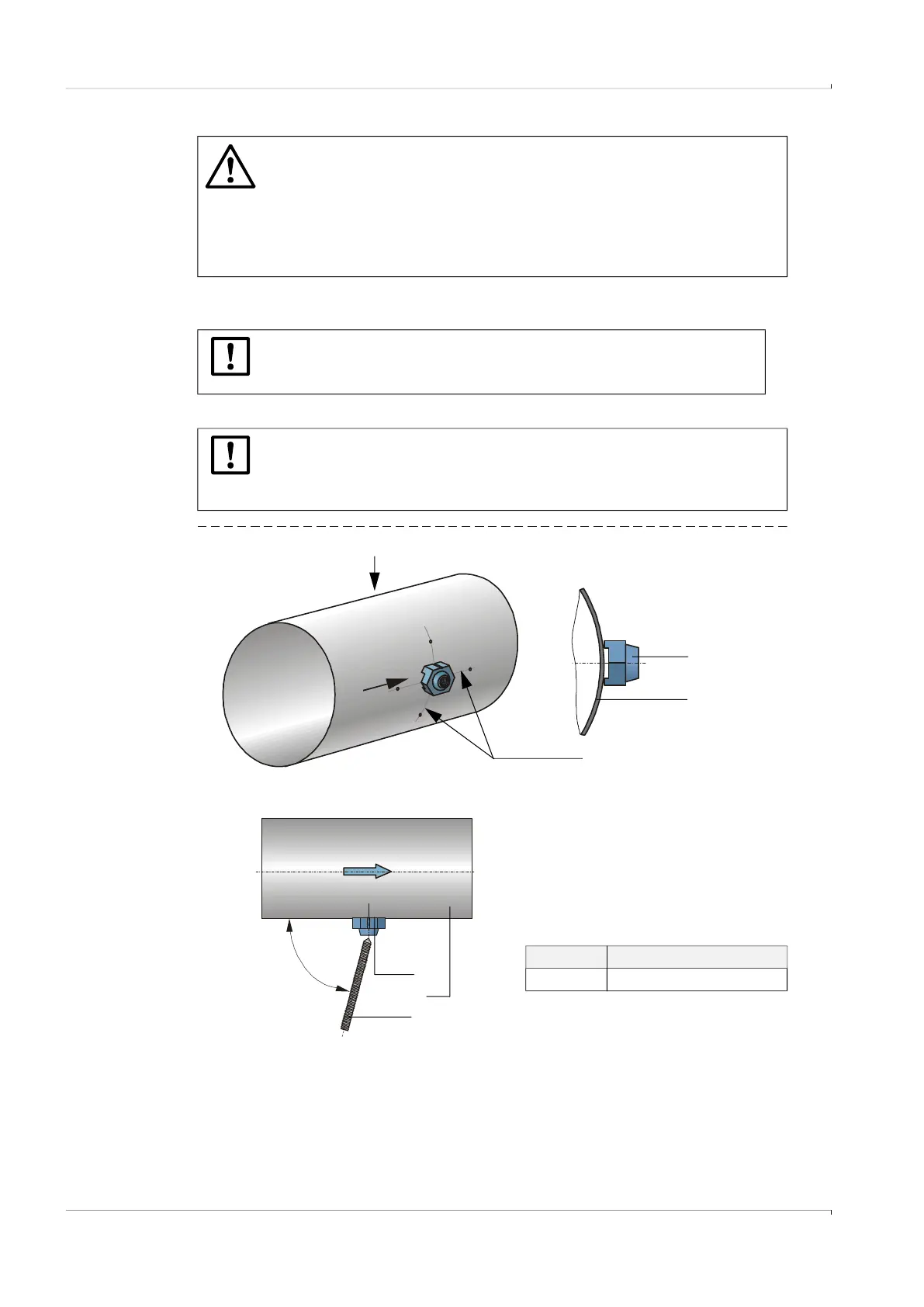

View B

Angle Type FLSE100-XT

75 ° F1F-S, F1F-M, F1F-H, F1F-P

1

3

Flow direction

1 Welding aid

2 Pipeline

3 Threaded rod

2

View B

Loading...

Loading...