Assembly and Installation

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH 55

Subject to change without notice

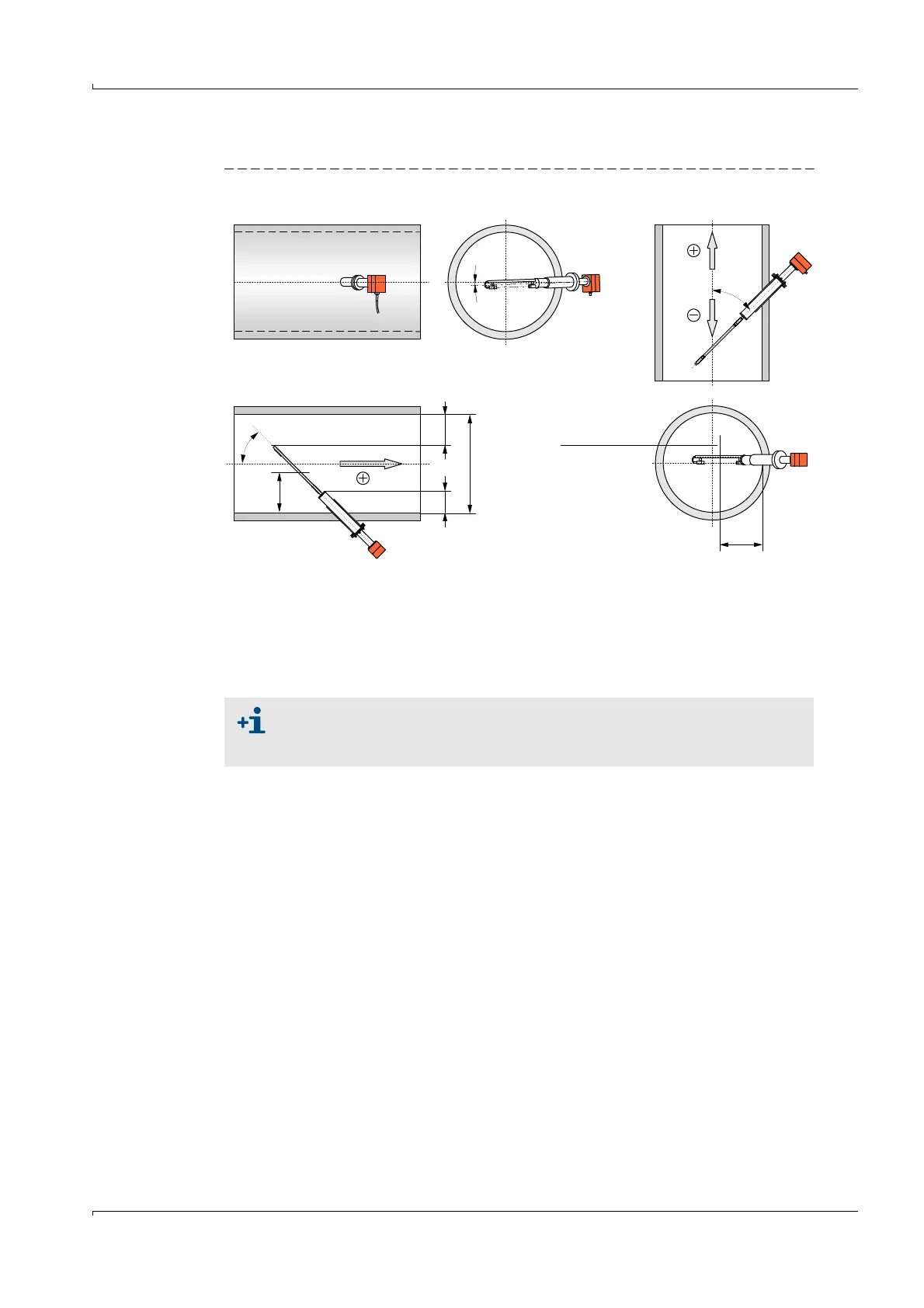

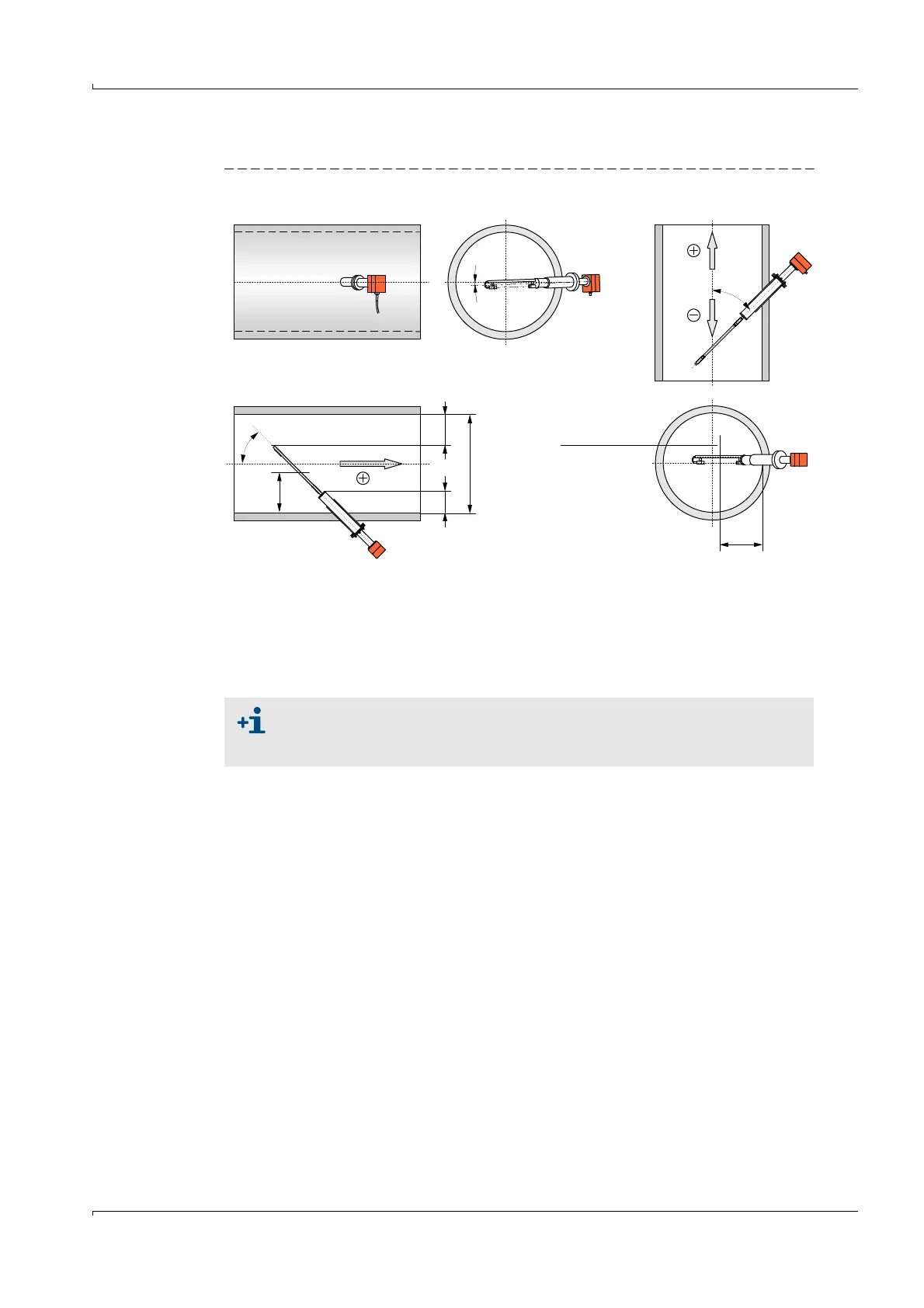

Installing the sender/receiver unit type FLSE100-PR

Fig. 29 Installing the sender/receiver unit type FLSE100-PR

Sender/receiver units with special lengths can be delivered if the condition for x with

standard nominal lengths cannot be observed.

Preventing condensate accumulations

If standard sender/receiver units are installed in vertical ducts, wet gases can cause

condensate to accumulate in the flange tube of sender/receiver unit A (

p. 15, Fig. 4). The

following onsite solutions can help prevent measuring problems (malfunctions caused by

structure-borne noise, see Service Manual), or damage when removing the sender/

receiver unit (condensate runs out):

● Completely insulating the flange with tube (reduces temperatures on the flange with

tube below the dew point)

● Draining continuous or periodical condensate through an opening (if necessary close-

able) at the deepest point of the flange tube (e.g. hole Ø 4 mm with plug:

Fig. 30) (only

when the condensate cannot damage the system or the environment)

● Returning the condensate to the duct through a hose connection between flange tube

and duct (

Fig. 30).

Horizontal duct

Di

45°

a

45°

1 ... 2°

b

x

x

Middle of trans-

ducer - transducer

distance

x = representative wall clearance at which the local gas flow rate is the same as the mean

velocity in the duct cross-section

Di = 0.35 ... 0.8 m:

a = b

Di > 0.8 m:

x 0.242 · Di /2

(accord. to ISO DIS

7145)

Vertical duct

In vertical ducts, a negative sign is shown on the LC-Display of the control unit

when the flow direction is from top to bottom. To change the displayed values

to positive values, enter a negative linear regression coefficient (

p. 144, 4.3).

Loading...

Loading...