62 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Assembly and Installation

Subject to change without notice

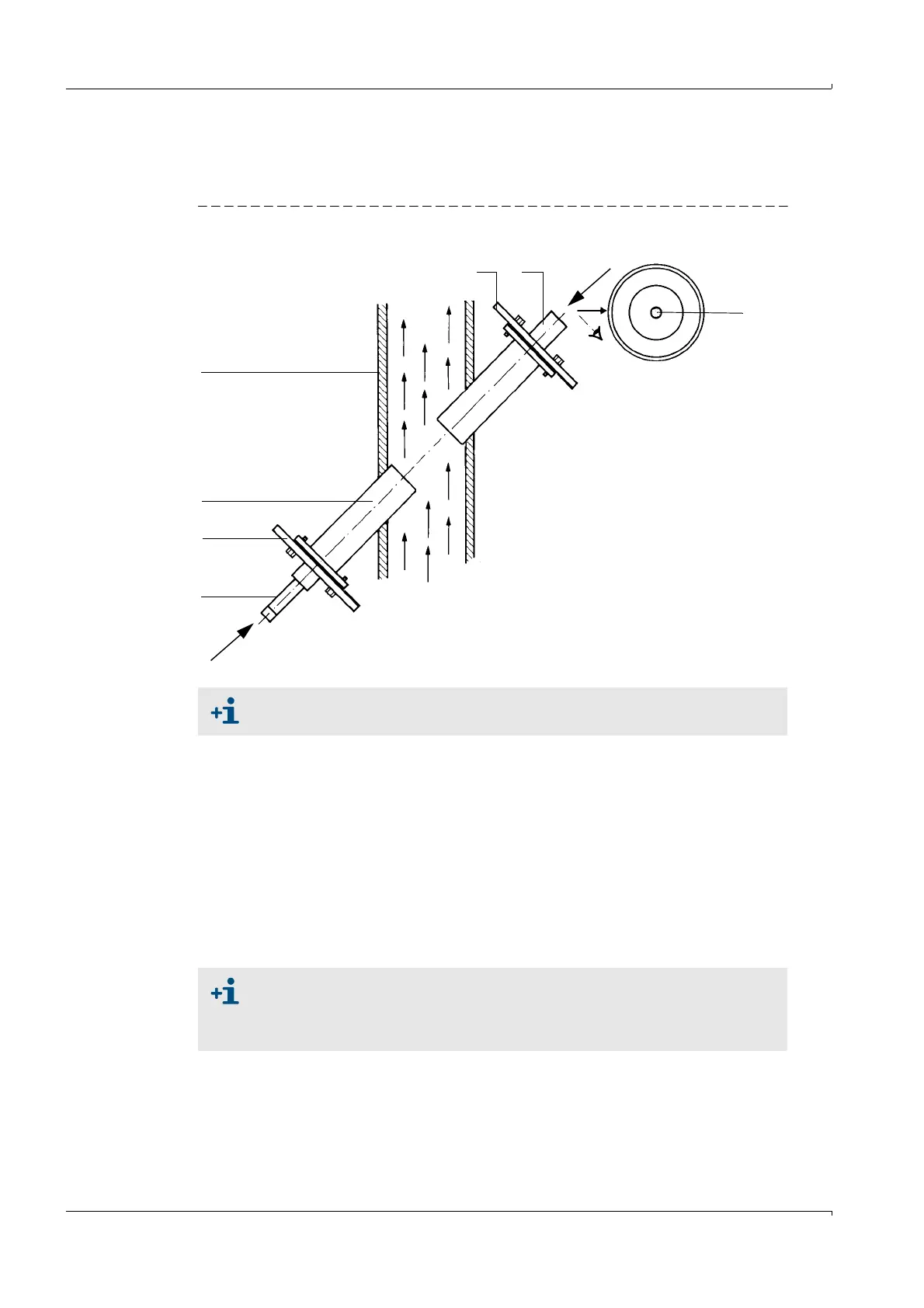

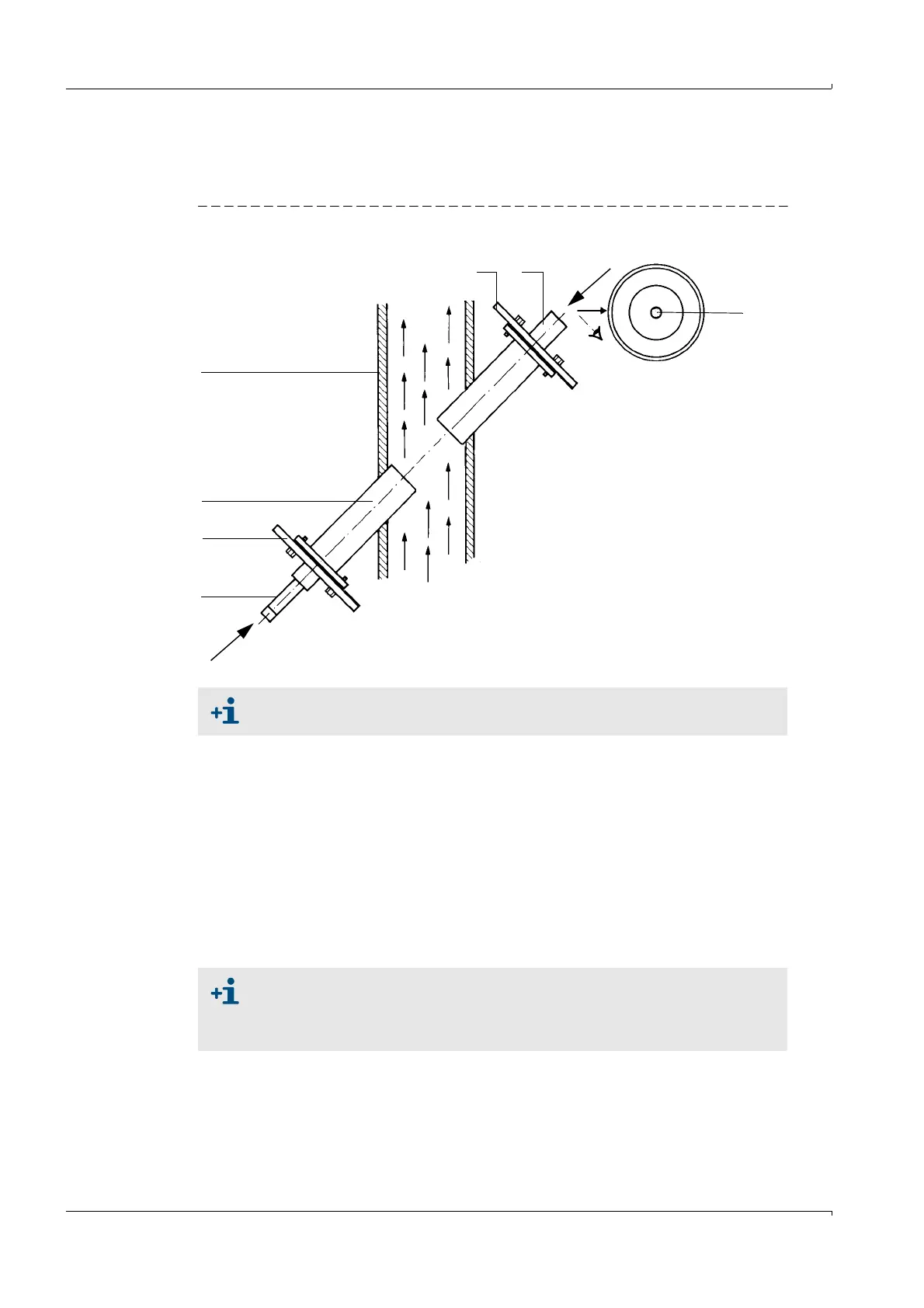

When fitting two flanges with tubes, align both exactly to each other after tacking using

a suitable tube (for smaller ducts) or using the SICK adjustment aid (can be provided on

loan) (see Fig. 35).

Fig. 35 Aligning the flange using the optical alignment device

Weld on the flange tubes, while constantly ensuring that the alignment is exact (correct

if necessary). When using the alignment device, first reposition the flange plate with

lamp and flange plate with target optics before welding the second flange tube on.

Measure and note the installation angle for configuring the parameters later.

Measure and note the distance between the two flanges (dimension F-F in Fig. 31) and

make a note of it for configuring the parameters later. The DME 2000 distance sensor

from SICK can be used (consult SICK, if required) for this purpose.

With thin-walled ducts/lines, provide suitable brackets/reinforcement to prevent distor-

tion and vibration (

p. 61, Fig. 34).

Seal the flange with a blind plug (optional).

Insulate the flange tube (if necessary).

Align the flange with target optics so that the light spot of the lamp appears

in the center of the target optics.

1 Lamp in adjusting device

2 Lamp flange plate

3Flange tube

4Duct

5 Target optic flange plate

6 Target optic, visor

7 Sight with optimum alignment

4

3

2

1

5

7

A

A

6

● When mounting two flanges with tube, the alignment of the two flange

tubes has priority over the installation angle.

● Distortions as a result of temperature changes or mechanical stresses can

change the measuring path.

Loading...

Loading...