Cycles

9.10 Oscillating plunge cutting - CYCLE426

Surface grinding

Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

177

9.10 Oscillating plunge cutting - CYCLE426

Programming

CYCLE426( N_SITZ, XSTART, XEND, YEND, ZEND, ZU_ART, KS, Y_A_LU, Y_A_SR,

Z_A_LU, Z_A_SR, LUZ, SRZ, N_FR, A_HEB, FR, FX)

Parameter

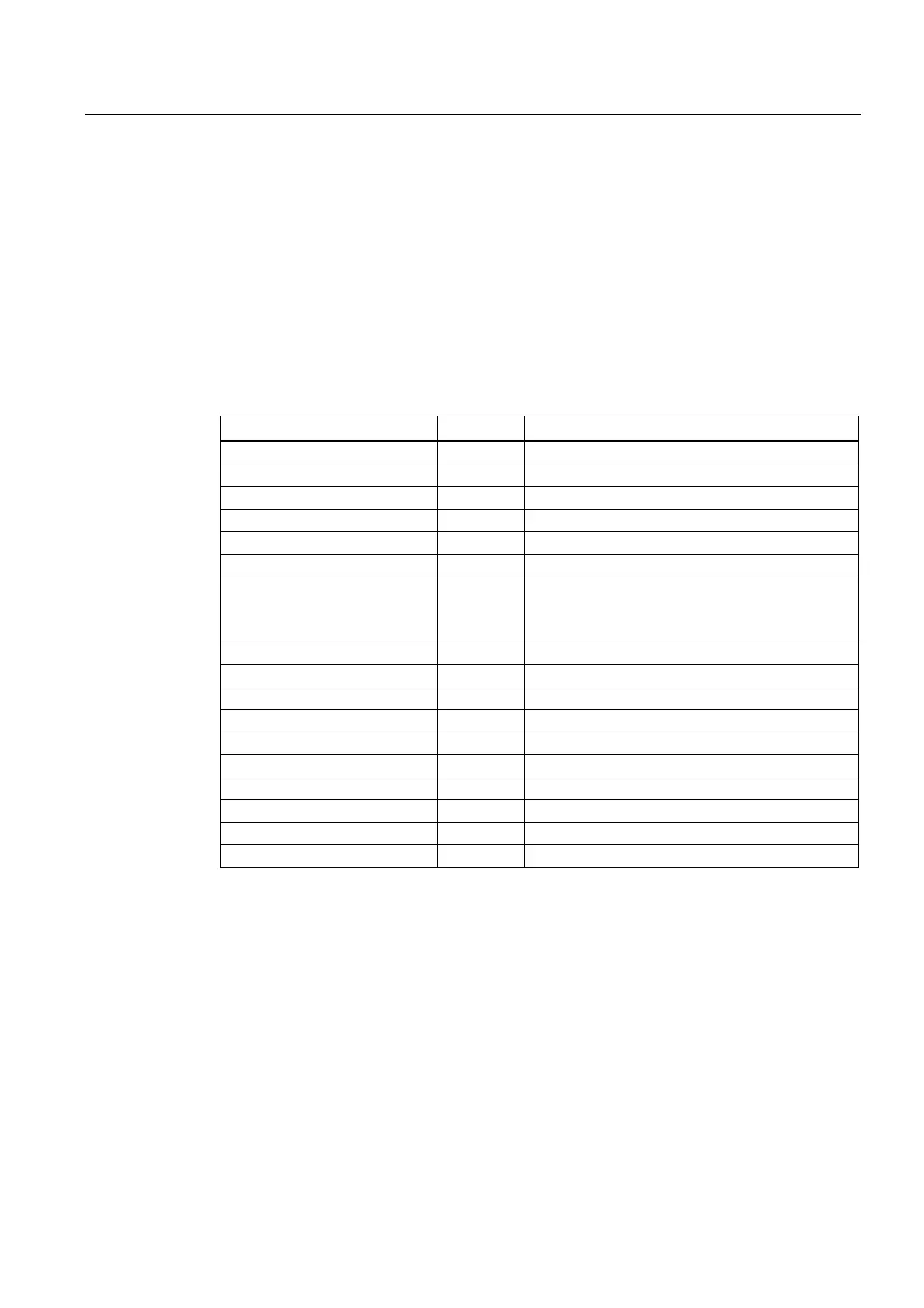

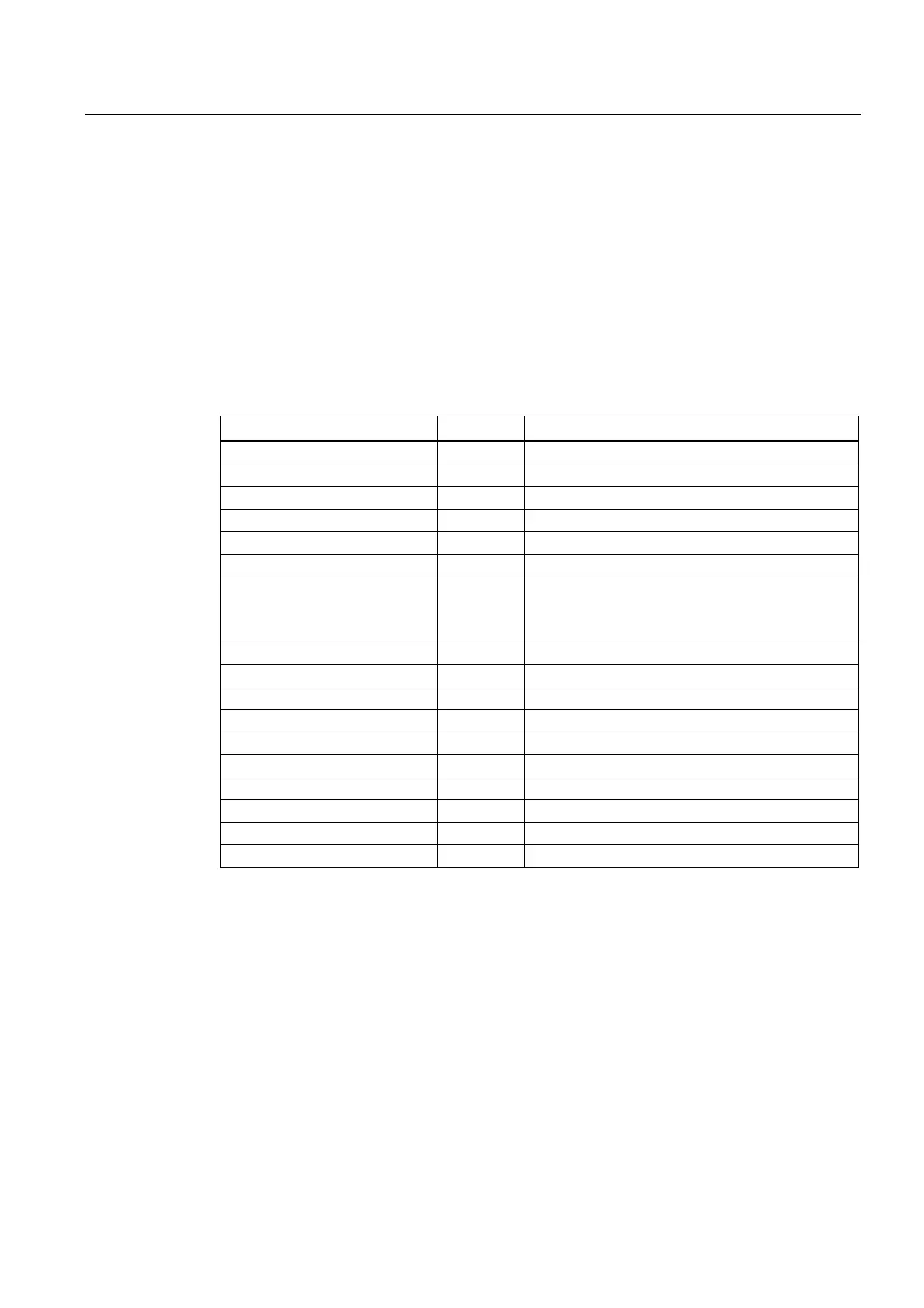

Table 9- 6 Parameters of CYCLE426

Parameter Data type Meaning

N_SITZ INT Seat number

XSTART REAL X axis starting position (abs)

XEND REAL X end position

YEND REAL Y end position

ZEND REAL Z end position

ZU_ART INT Infeed left/right/both sides

KS INT with structure-borne noise

0=no

1=yes

Y_A_LU REAL Air grinding allowance (incr.)

Y_A_SR REAL Allowance (incr.)

Z_A_LU REAL Air grinding allowance (incr.)

Z_A_SR REAL Allowance (incr.)

LUZ REAL Air grinding feedrate, per stroke

SRZ REAL Infeed per stroke

N_FR REAL Number of sparking-out strokes

A_HEB REAL Retraction amount (incr.)

FR REAL Feedrate at reversal point

FX REAL Table feedrate

Function

The oscillating plunge cutting cycle is called for the purpose of machining a slot or surface

that is smaller than the wheel width. It can also be used for grinding front faces. The surface

concerned is ground using the oscillation method.

Infeed takes place at the reversal points. Intermediate dressing, interruption and use of the

handwheel are all supported.

The keys will only ever respond at the end point.

At the end, the tool retracts or grinding continues with a different technology.

Infeed is possible in the Y or Z directions and the Z value can be either negative or positive.

Loading...

Loading...