Appendix

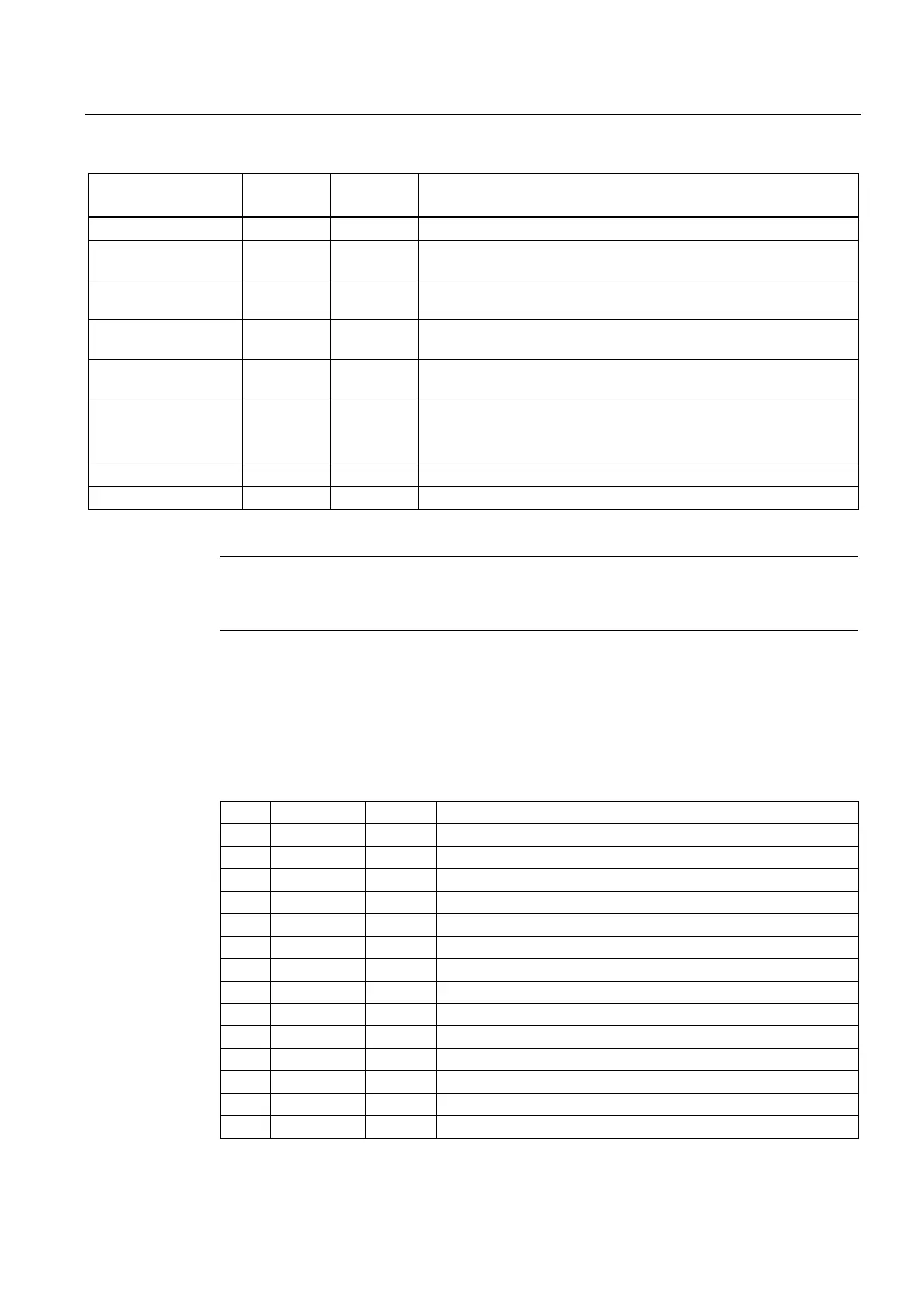

A.2 Parameter tables of the tool data

Surface grinding

Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

341

Name Type Default

Value

Description

_GC_FWEG REAL Free wheel travel path (measurement control)

_GC_SEARCHS Tag for seat regrinding is evaluated by the cycles so that the

individual seat can be identified via a block search.

_GC_SEARCH Tag for seat regrinding is evaluated by the cycles so that the

individual seat can be identified via a block search.

_GC_SEARCHSET Tag for seat regrinding is evaluated by the cycles so that the axes

can be recalibrated.

_GC_SEACRHVALUE[

0..2]

Regrinding calibration values

_GC_SUGFEED Independent of basic system

0 = GWPS in m/s

1 = GWPS in feed/min

_GC_MF[18] Enable program level abort of CYCLE448

_GC_MF[19] Blocking and resetting of last program level abort

Note

The values stored as the default must be checked by the machine manufacturer and

adapted to the realities of the machine.

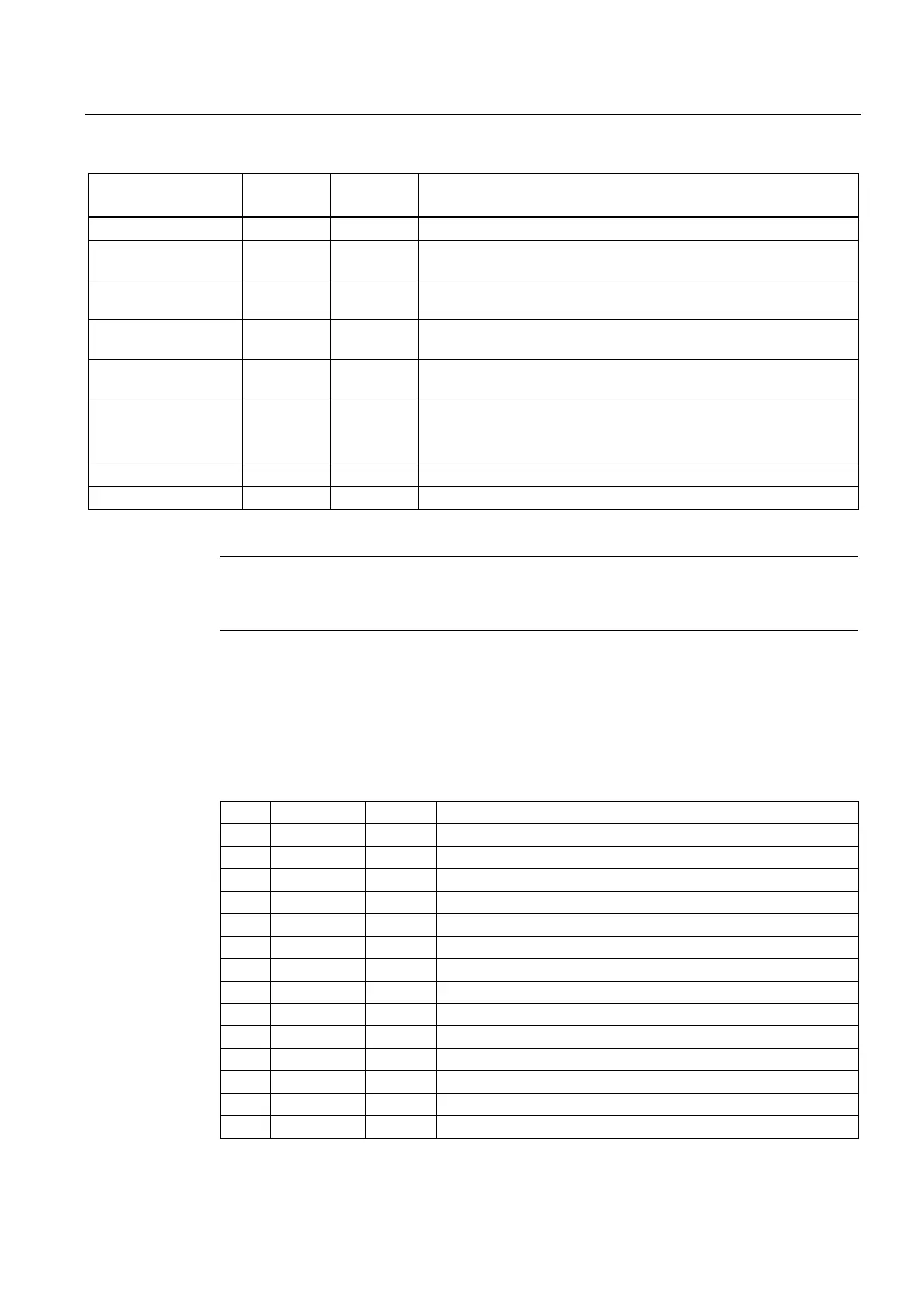

A.2 Parameter tables of the tool data

The following parameters, operated from the HMI, are available for the tool offsets.

Table A- 1 Grinding wheel data, x=[1...n] y=[1...6]

Tx TPG1 INT Spindle number

Tx TPG2 INT Concatenation rule = 0

Tx TPG3 REAL Min. wheel diameter

Tx TPG4 REAL Min. wheel width

Tx TPG5 REAL Current grinding wheel width

Tx TPG6 REAL Maximum speed

Tx TPG7 REAL Maximum GWPS

Tx TPG8 REAL Angle of inclined wheel

Tx TPG9 INT Parameter no. for radius calculation

Tx TPC1 REAL Wheel type (vertical, inclined, free)

Tx TPC2 REAL Amount of crown

Tx TPC3 REAL Dressing amount

Tx TPC4 REAL Cylindric compensation

Tx TPC5 REAL GWPS

Loading...

Loading...