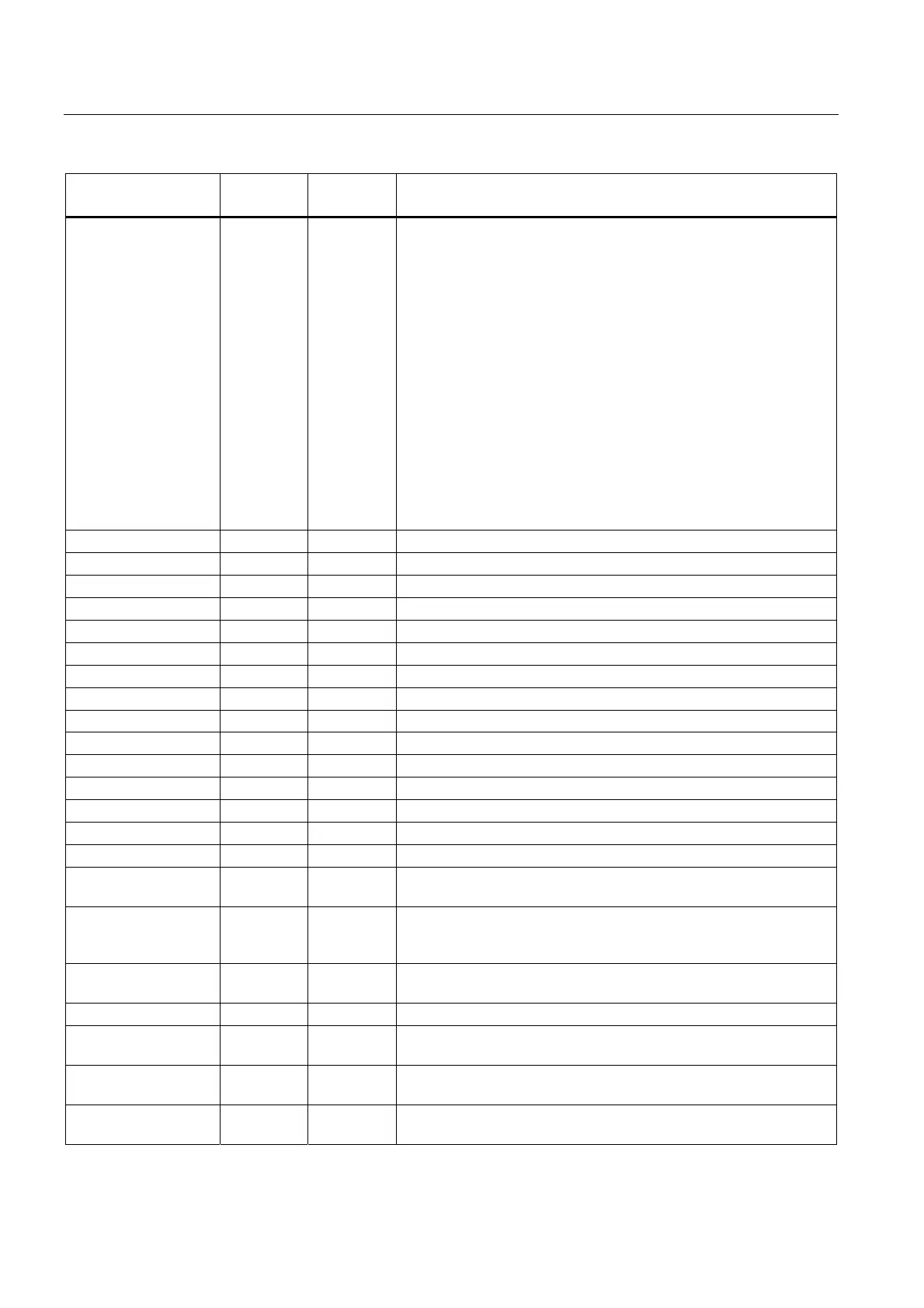

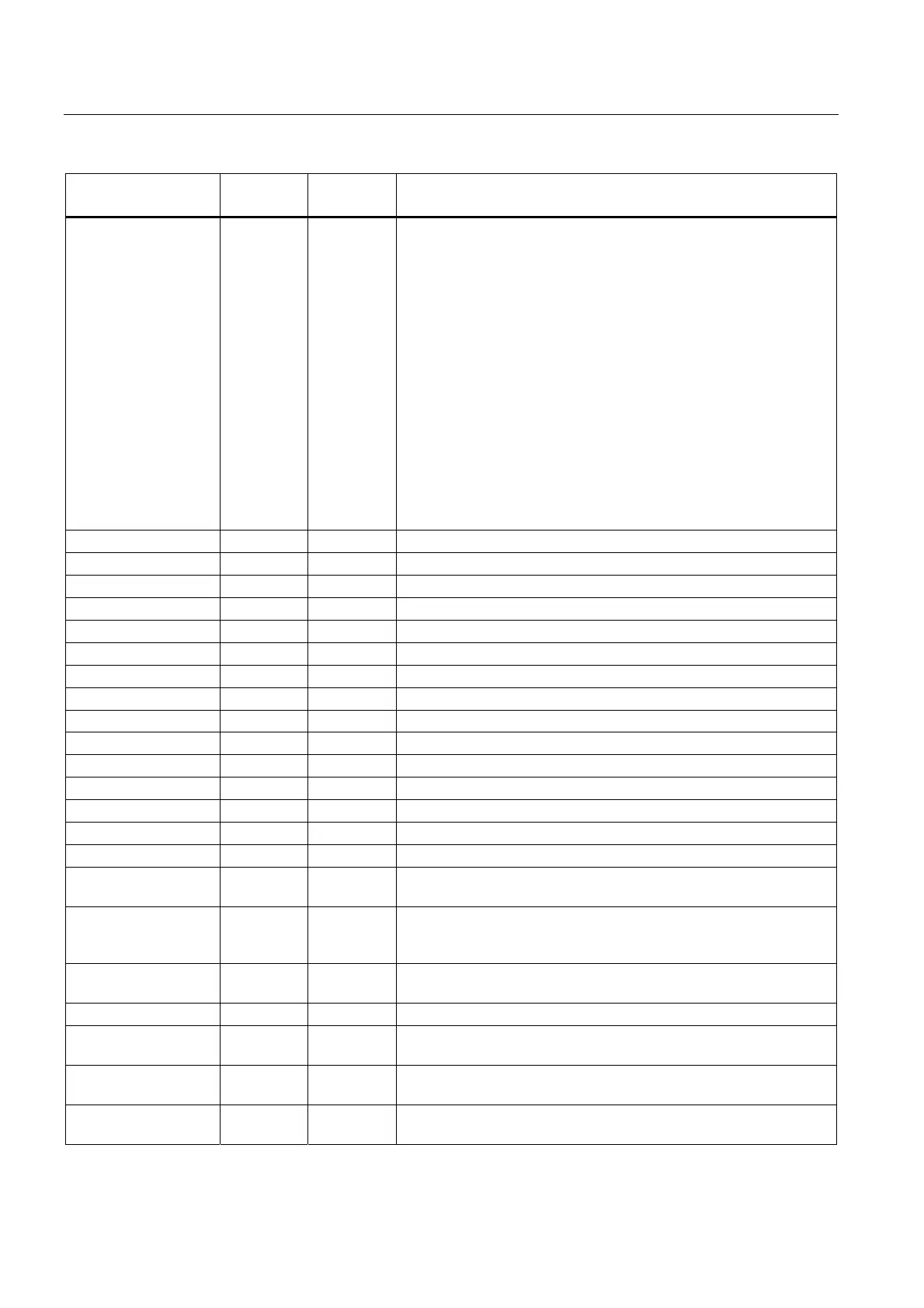

Appendix

A.1 User data

Surface grinding

340 Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

Name Type Default

Value

Description

_GC_MF[0]

_GC_MF[1]

_GC_MF[2]

_GC_MF[3]

_GC_MF[4]

_GC_MF[5]

_GC_MF[6]

_GC_MF[7]

_GC_MF[8]

_GC_MF[9]

_GC_MF[10]

_GC_MF[11]

_GC_MF[12] .

_GC_MF[13]

_GC_MF[14]

_GC_MF[15]

_GC_MF[16]

_GC_MF[17]

INT 3

21

22

33

34

41

42

65

66

80

81

4

7

9

Grinding spindle direction of rotation (M3)

Swing in measurement control (M21)

Swing out measurement control (M22)

Structure-borne noise ON (M33)

Structure-borne noise OFF (M34)

Advance dresser (M41)

Retract dresser (M42)

Swing out caliper (M65)

Swing in caliper (M66)

Enable handwheel (M80)

Disable handwheel (M81)

Workpiece spindle direction of rotation (M4)

Coolant ON (M7)

Coolant OFF (M9)

Swing in measurement control, program control (M23)

Swing out measurement control, program control (M24)

Disable stroke reversal if no longitudinal stroke (M27)

Enable stroke reversal if longitudinal stroke (M28)

Number of inputs IN:

_GC_IN_KS INT 16 Acoustic emission sensor

_GC_IN_MZ0 INT 9 Retract measurement control

_GC_IN_MZ1 INT 10 Time measurement control

_GC_IN_MZ2 INT 11 Switch-over fine finishing measurement control

_GC_IN_MZ3 INT 12 Switch-over finishing measurement control

_GC_IN_MZ4 INT 13 Reserved for inputs/outputs

_GC_IN_ABR INT 14 Intermediate dressing upon key

_GC_IN_HAND INT 15 Handwheel key

_GC_IN_BREAK INT 13 Program interrupt key

_GC_IN_HUB INT 12 Stroke reversal key

_GC_IN_FEEDSTOP INT 11 Infeed stop key

_GC_WEARTYP INT 0 Selection of wear compensation, comparison or nominal dimensions

_GC_SSTAT INT Selection ... with/without grinding spindle monitoring

_GC_FEIN[2] REAL Global fine compensation

_GC_FEIN[0]

_GC_FEIN[1]

REAL Incremental X fine compensation

Incremental Z fine compensation

_GC_SFEIN[10,2] REAL Fine compensation seat-specific

1st index … seat number

2nd index ... axis

_GC_RLZTYP INT 0 Do not approach the return position of the Z-axis in -1-, MCS=0

WCS=1

_GC_RLXTYP INT 0 Type of return position in

_GC_RLX REAL X return position; dresser or workpiece can be collision-free

approached using a machine specific return position

_GC_RLZ REAL Z return position; dresser or workpiece can be approached without

collision using a machine-specific return position.

_GC_BT REAL Measurement control tolerance in which a measurement control

signal is expected

Loading...

Loading...