Cycles

9.13 Profile grinding - CYCLE429

Surface grinding

186 Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

9.13 Profile grinding - CYCLE429

Programming

CYCLE429( N_SITZ, XSTART, ZSTART, YEND, KS, A_LU, A_SR, LUZ, SRZ, N_FR,

A_HEB, FX, KONTUR)

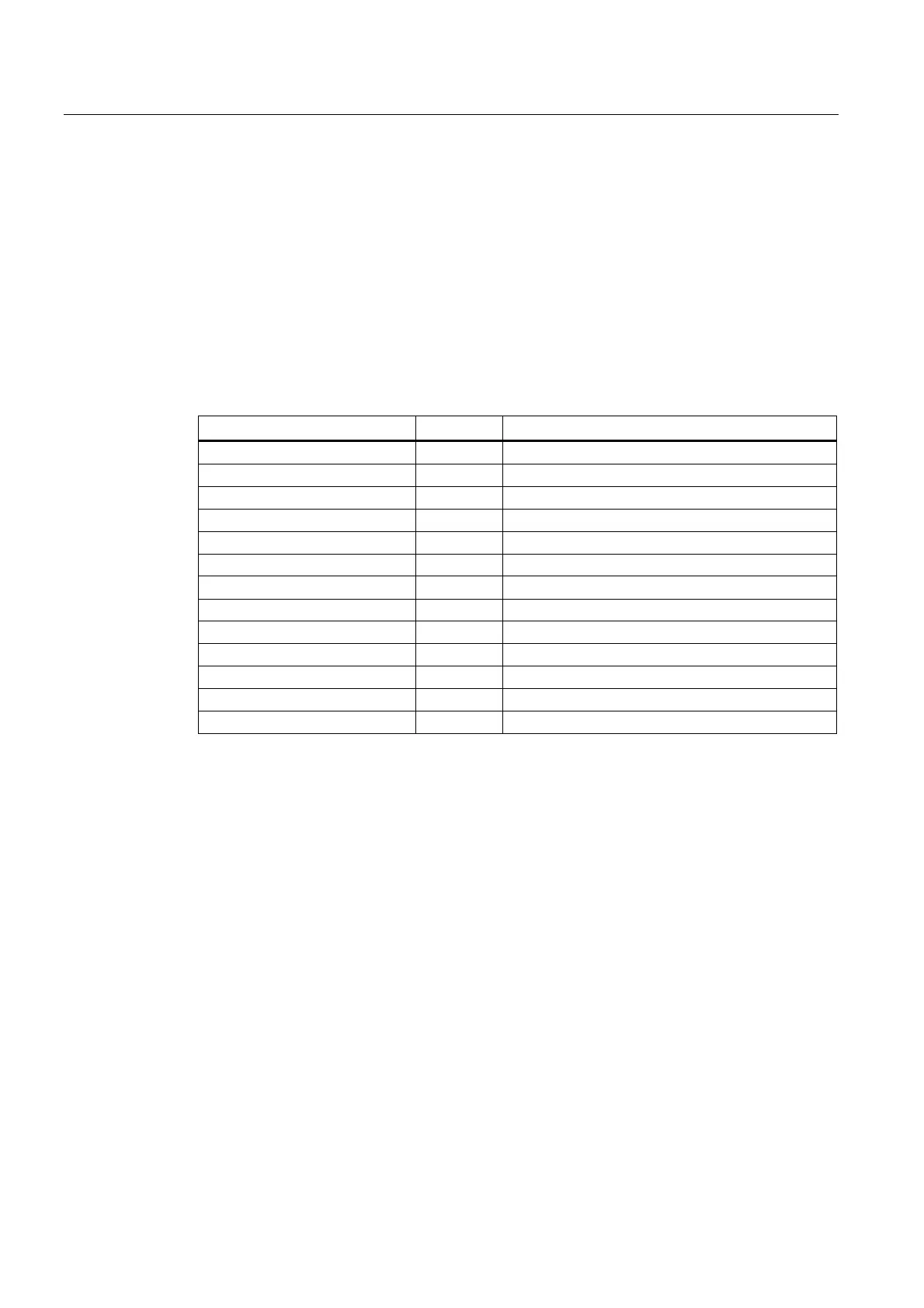

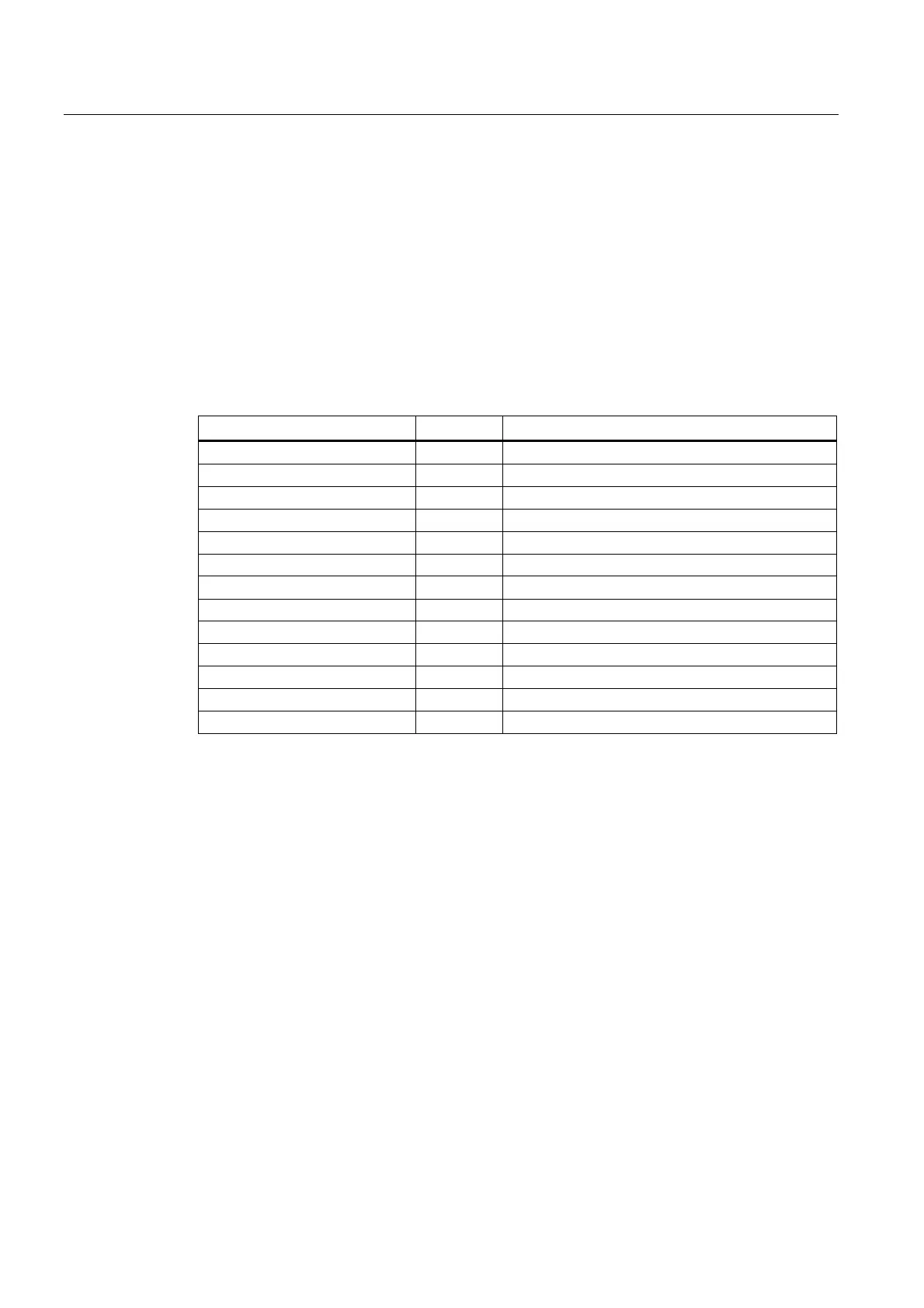

Parameter

Table 9- 9 Parameters of CYCLE429

Parameter Data type Meaning

N_SITZ INT Seat number

XSTART REAL X axis starting position (abs)

ZSTART REAL Z axis starting position (abs)

YEND REAL Y end position

KS INT with structure-borne noise 0 = no 1 = yes

A_LU REAL Air grinding allowance (incr.)

A_SR REAL Allowance (incr.)

LUZ REAL Air grinding feedrate, per stroke

SRZ REAL Infeed per stroke

N_FR REAL Number of sparking-out strokes

A_HEB REAL Retraction amount (incr.)

FX REAL Table feedrate

KONTUR String Contour name

Function

The profile grinding cycle is called for the purpose of machining a surface with a free

contour.

The entire contour is contained within the contour subroutine.

The cycle merely handles the infeed process and the interrupt keys, which do not have any

effect until the end of the contour is reached.

Both intermediate dressing and interruption are supported.

At the end of each stroke, retraction is performed followed by a return to the starting point.

Machining must be performed using active tool nose radius compensation (G41/G42).

The tool offset is modified by the cycle.

The user has the option of programming both an outward and a return motion in the free

contour. In this case, no retraction amount is required.

The user must select the correct G group (G41/G42) in the contour program, because this

program also happens to contain the machining direction.

Loading...

Loading...