Programming

10.2 Positional data

Surface grinding

212 Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

10.2.3 Absolute/incremental dimensioning: G90, G91, AC, IC

Functionality

With the instructions G90/G91, the written positional data X, Y, Z, ... are evaluated as a

coordinate point (G90) or as an axis position to traverse to (G91). G90/G91 applies to all

axes.

Irrespective of G90/G91, certain positional data can be specified for certain blocks in

absolute/incremental dimensions using AC/IC.

These instructions do not determine the path by which the end points are reached; this is

provided by a G group (G0, G1, G2 and G3... see Chapter "Axis Movements").

Programming

G90 ; Absolute dimension data

G91 ; Incremental dimension data

X=AC(...) ; Absolute dimensioning for a certain axis (here: X axis), non-modal

X=IC(...) ; Absolute dimensioning for a certain axis (here: X axis), non-modal

3

<

3

3

;

3

<

3

3

;

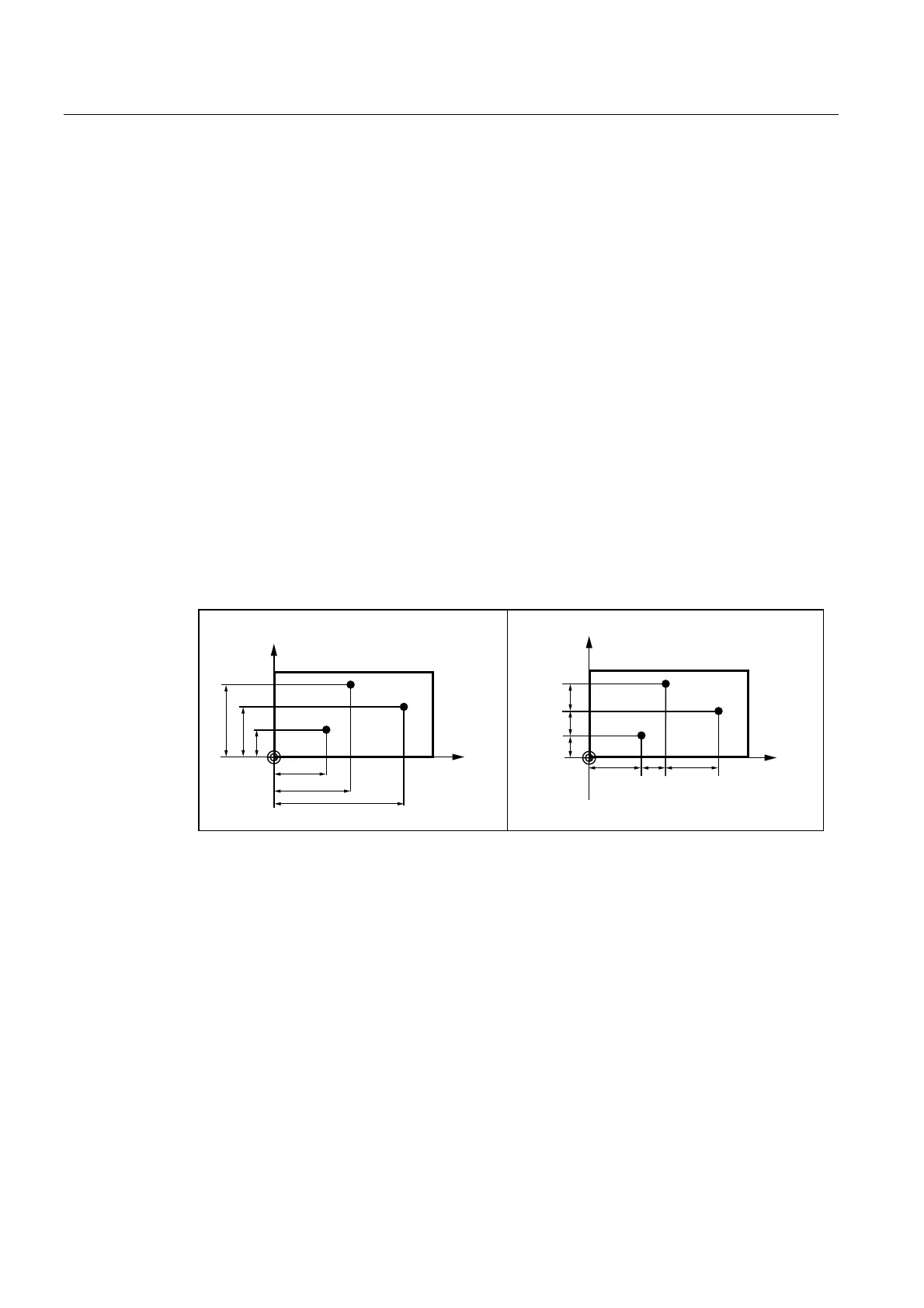

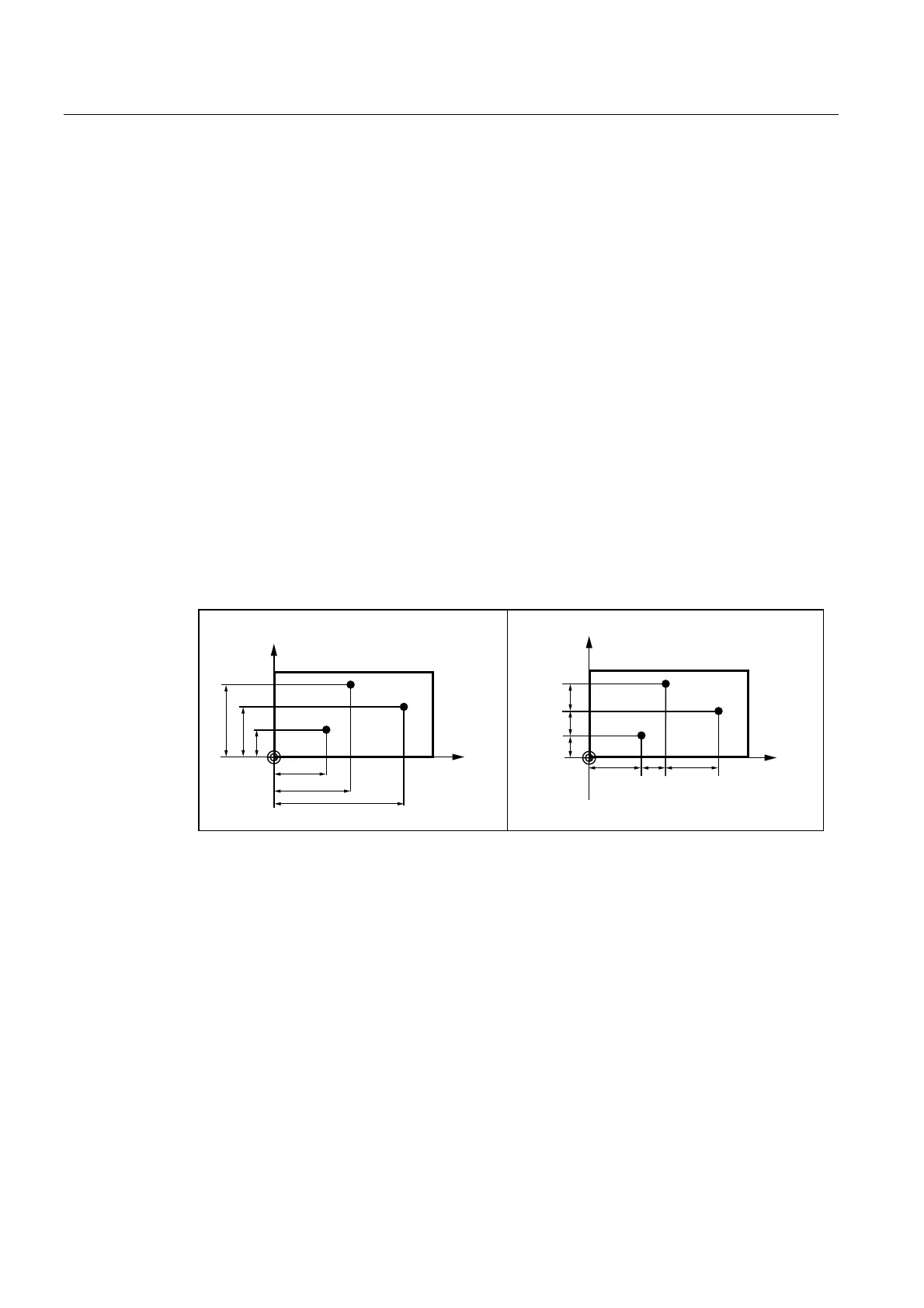

,QFUHPHQWDOGLPHQVLRQ

$EVROXWHGLPHQVLRQV

Figure 10-4 Different dimensioning types in the drawing

Absolute dimensioning G90

With absolute dimensioning, the dimensioning data refers to the zero of the coordinate

system currently active (workpiece or current workpiece coordinate system or machine

coordinate system). This is dependent on which offsets are currently active: programmable,

settable, or no offsets.

Upon program start, G90 is active for all axes and remains active until it is deselected in a

subsequent block by G91 (incremental dimensioning data) (modally active).

Incremental dimensioning G91

With incremental dimensioning, the numerical value of the path information corresponds to

the axis path to be traversed. The leading sign indicates the traversing direction.

Loading...

Loading...