Description

1.5 Coordinate systems

Surface grinding

Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

19

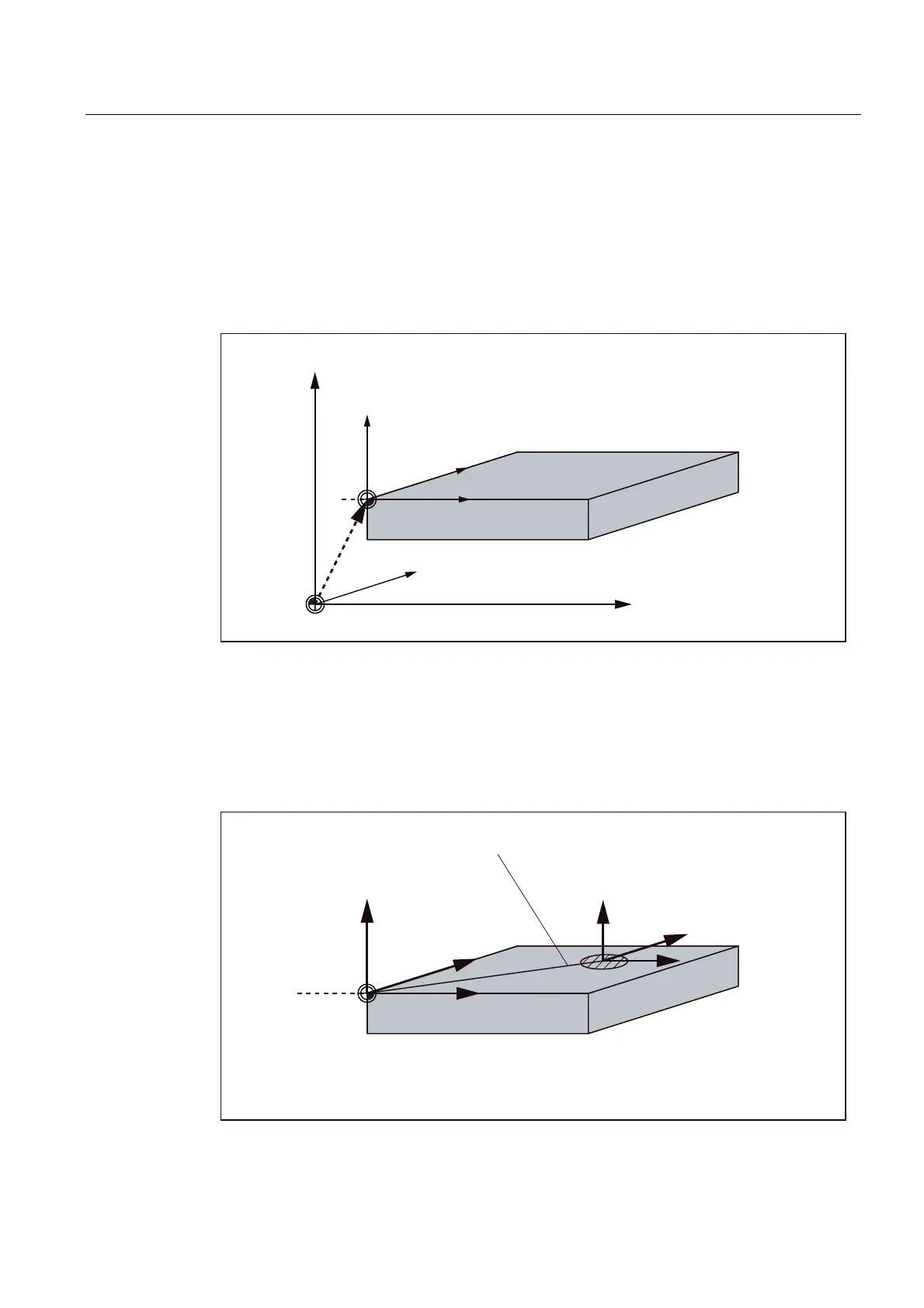

Clamping the workpiece

For machining, the workpiece is clamped on the machine. The workpiece must be aligned

such that the axes of the workpiece coordinate system run in parallel with those of the

machine. Any resulting offset of the machine zero with reference to the workpiece zero is

determined along the Y axis and entered in a data area intended for the settable work offset.

In the NC program, this offset is activated during program execution, e.g. using a

programmed G54.

: ZRUNSLHFH]HUR

0 PDFKLQH]HUR

:

<

ZRUNSLHFH

;

=

<

PDFKLQH

=

PDFKLQH

;

PDFKLQH

HJ*

0

Figure 1-6 Workpiece on the machine

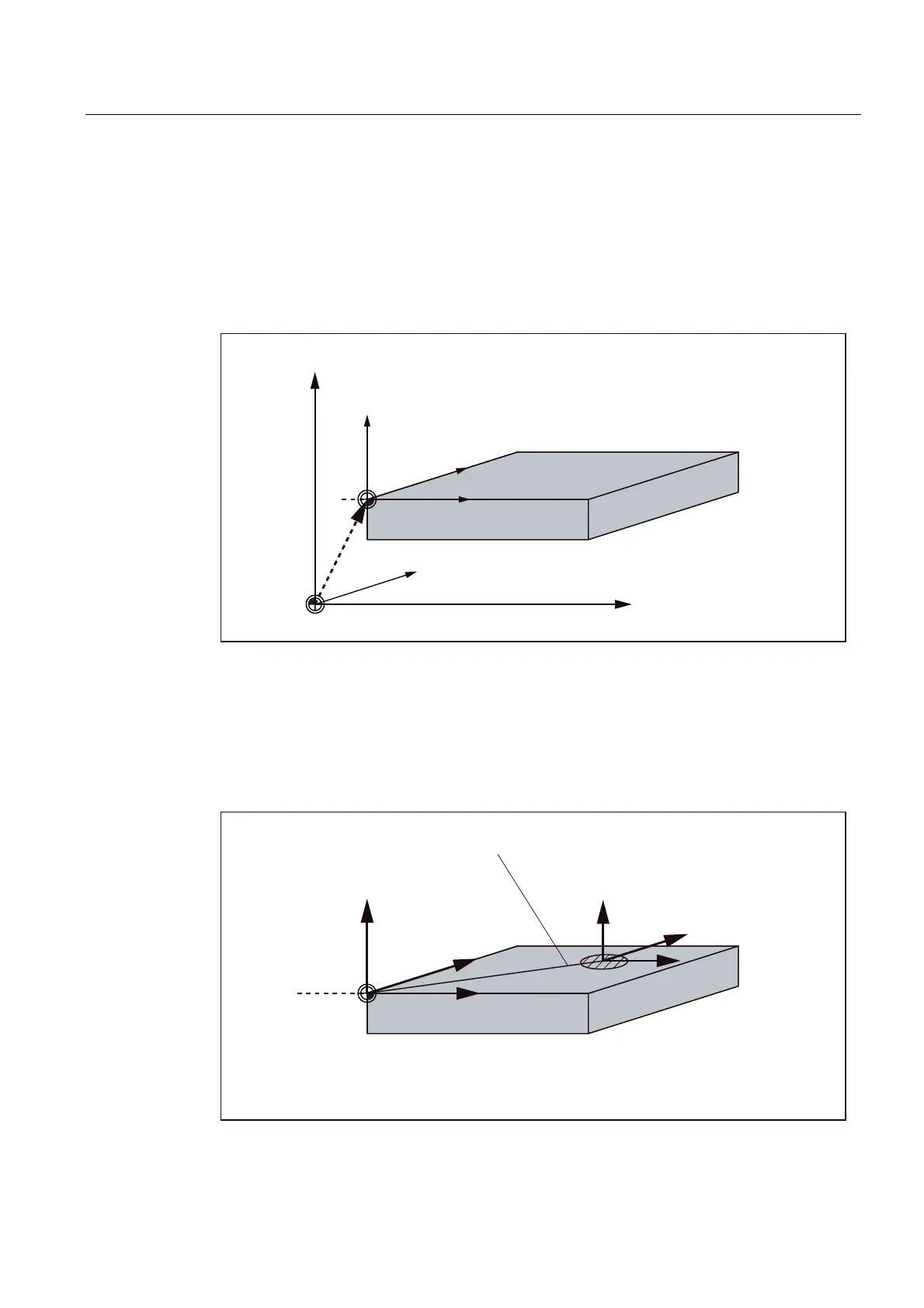

Current workpiece coordinate system

The programmed work offset TRANS can be used to generate an offset with reference to the

workpiece coordinate system. resulting in the current workpiece coordinate system (see

Section "Programmable work offset: TRANS").

: ZRUNSLHFH]HUR

:

<

;

=

3URJUDPPDEOHRIIVHW

75$16

<

;

=

&XUUHQW

Figure 1-7 Coordinates on the workpiece; current workpiece coordinate system

Loading...

Loading...