01.99 1 Introduction - SINUMERIK 840C and its Operation

© Siemens AG 1999 All Rights Reserved 6FC5198-6AA60-0BP1

SINUMERIK 840C, OEM Version for Windows (BA)

1-3

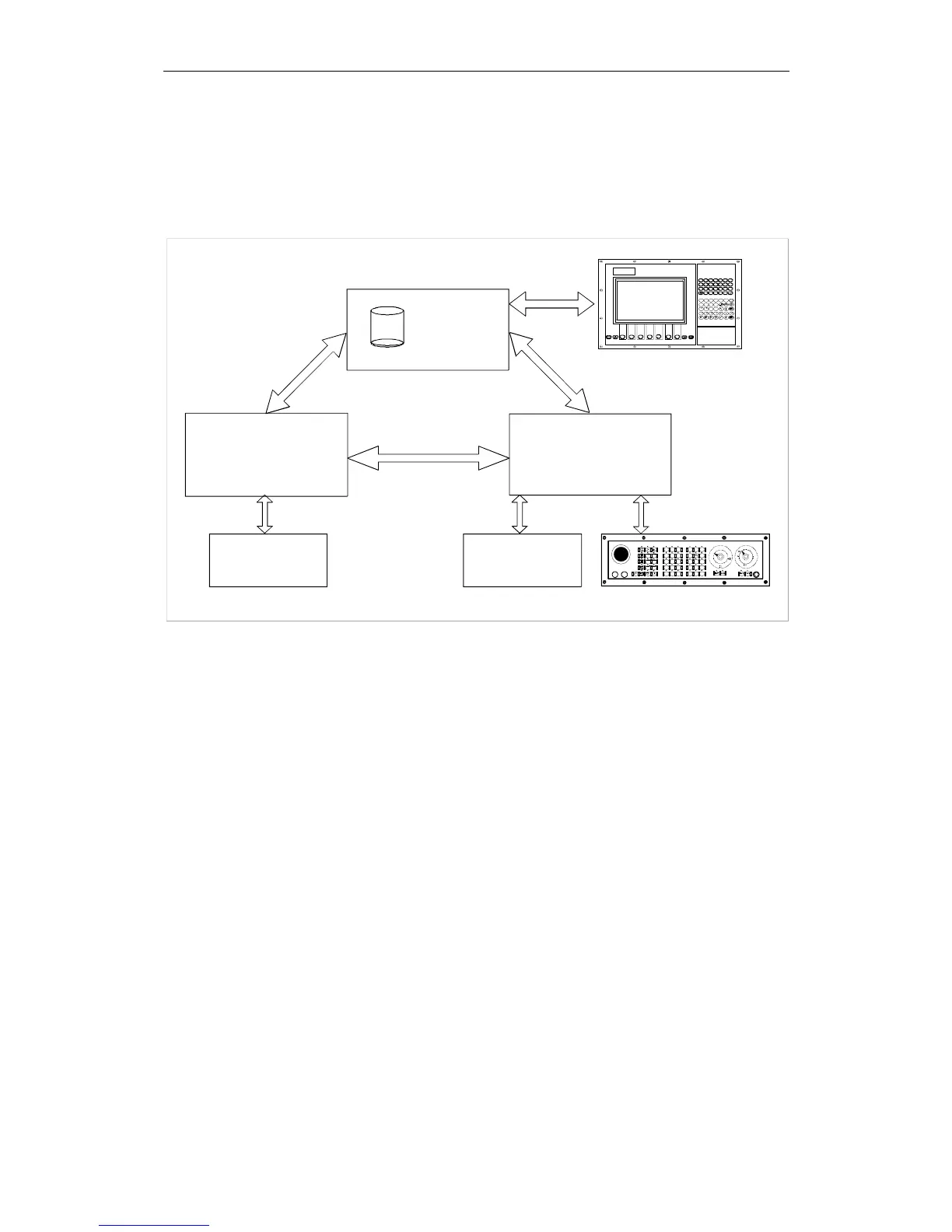

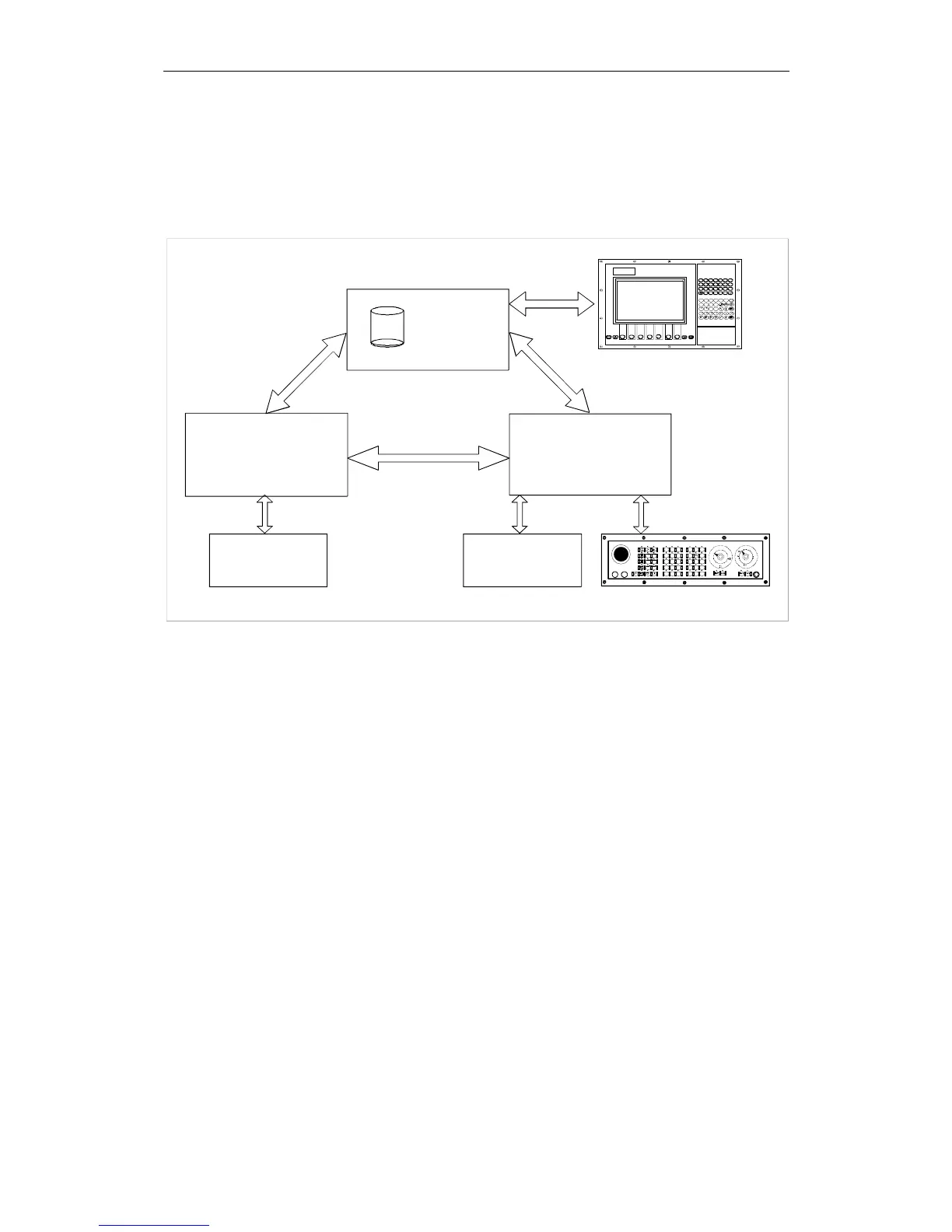

1.2 Design of the control

Structurally, the SINUMERIK 840C CNC can be divided into the following

three components:

A B C D E F G

H I J K L M N

O P Q R S T U

V W X Y Z

7

(

8

)

9

:

/

"

4

[

5

]

6

?

*

’

1 2 3

!

-

^

= 0 . +

%LF

Alt

\

i

SIEM ENS

SINUMERI K

M

NCK

PLC

MMC

%

0

2

10

40

60

70

80

90

100

110

120

50

60

70

80 90

100

120

%

[ . ] 1

10 100

1000 10 00 0

+X +C

-Z +Z

-C -X

Setpoints/actual values

for axes and spindles

Machine control

input/output

Fig. 1-1 Structure of SINUMERIK 840C

The three components perform the following functions:

The main task of the NCK (NC kernel) is to convert the program blocks of a

part program into the traversing movements on the axes. Allowance must be

made for all the required compensating values such as tool offsets, zero offsets,

etc.

The PLC mainly performs simple control and monitoring tasks. The PLC

program must assure the smooth execution of all machine functions without

endangering man or machine.

A PC has been integrated in the SINUMERIK 840C CNC for MMC (Man

Machine Communication). In addition to data management tasks, this PC

performs functions related mainly to the transfer and visualization of data

exchanged between the NCK, PLC, MMC and operator. This PC runs under

the MS-Windows operating system.

NCK

PLC

MMC=PC

Loading...

Loading...