5 Parameters 01.99

6FC5198-6AA60-0BP1 © Siemens AG 1999 All Rights Reserved

5-10 SINUMERIK 840C, OEM Version for Windows (BA)

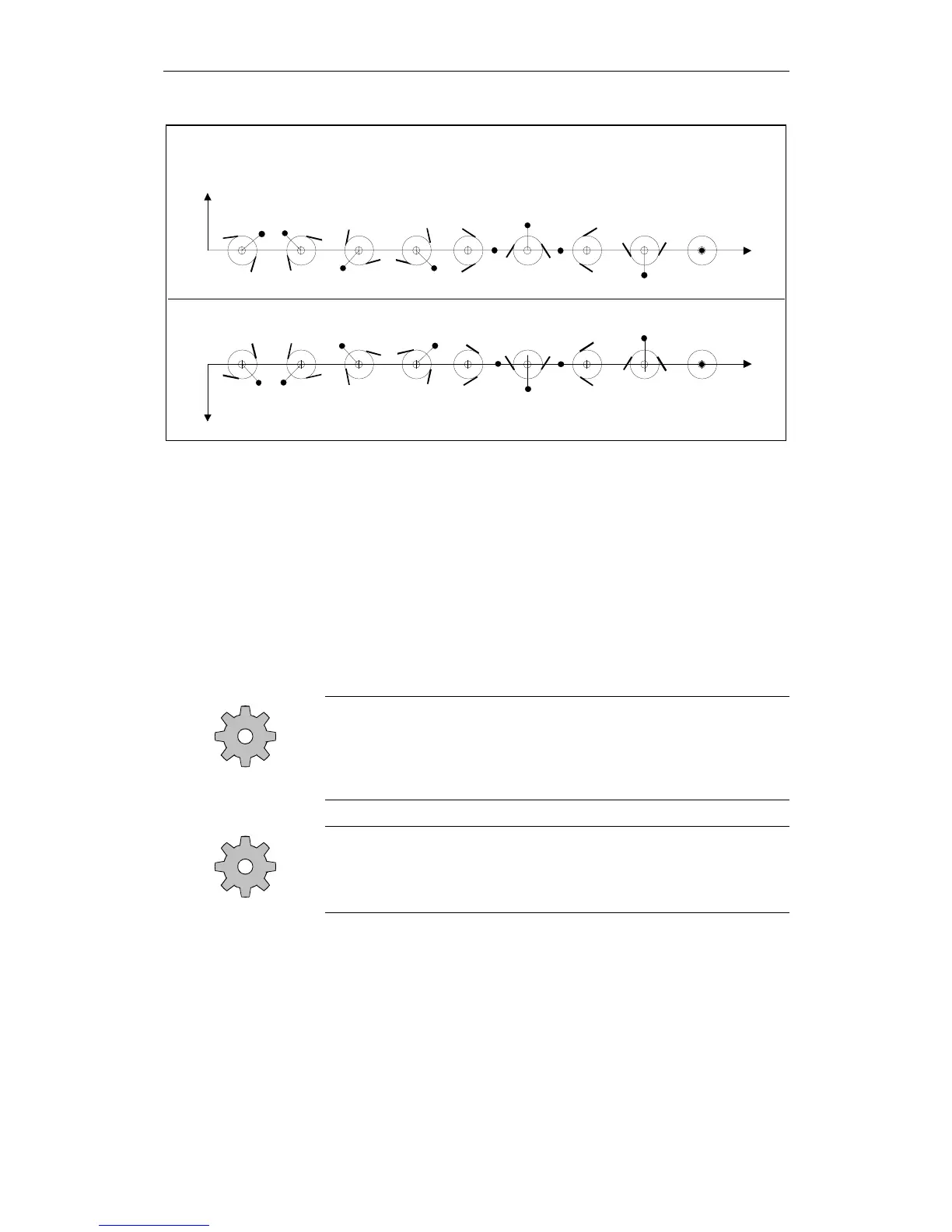

S

S

S

+X

+Z

P1 = 1 P1 = 9P1 = 8P1 = 7P1 = 6P1 = 5P1 = 4P1 = 3P1 = 2

P = S

+X

+Z

P1 = 1 P1 = 9P1 = 8P1 = 7P1 = 6P1 = 5P1 = 4P1 = 3P1 = 2

P = S

Tool point direction when machining

behind

the turning centre

Tool point direction when maching

in front

of the turning centre

P

P

S

P

Fig. 5-6 Tool point direction

L1 geometry, L2 geometry, diameter/radius.

See Fig. 5-5 Tool types.

L1 wear, L2 wear, diameter/radius. For the TO parameters "5" to "7", it is

possible (but not absolutely necessary) to enter the wear data of the tool in the

input screenform.

L1 base, L2 base.

The TO parameters "8" and "9" are provided for special applications. The

"Base dimension" makes a further tool length compensation possible.

Machine manufacturer

It is possible to disable input of the geometry and wear data of the tool by

means of a keyswitch. Please refer to the machine-tool manufacturer’s

documentation!

Machine manufacturer

The maximum standard wear value in parameters P5 to P7 is 9.999 mm.

This limit can be modified by the machine manufacturer.

TO parameters

2 to 4

TO parameters

5 to 7

TO parameters

8 and 9

Loading...

Loading...