Alarm, error, and system messages

10.4 Fault correction

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

229

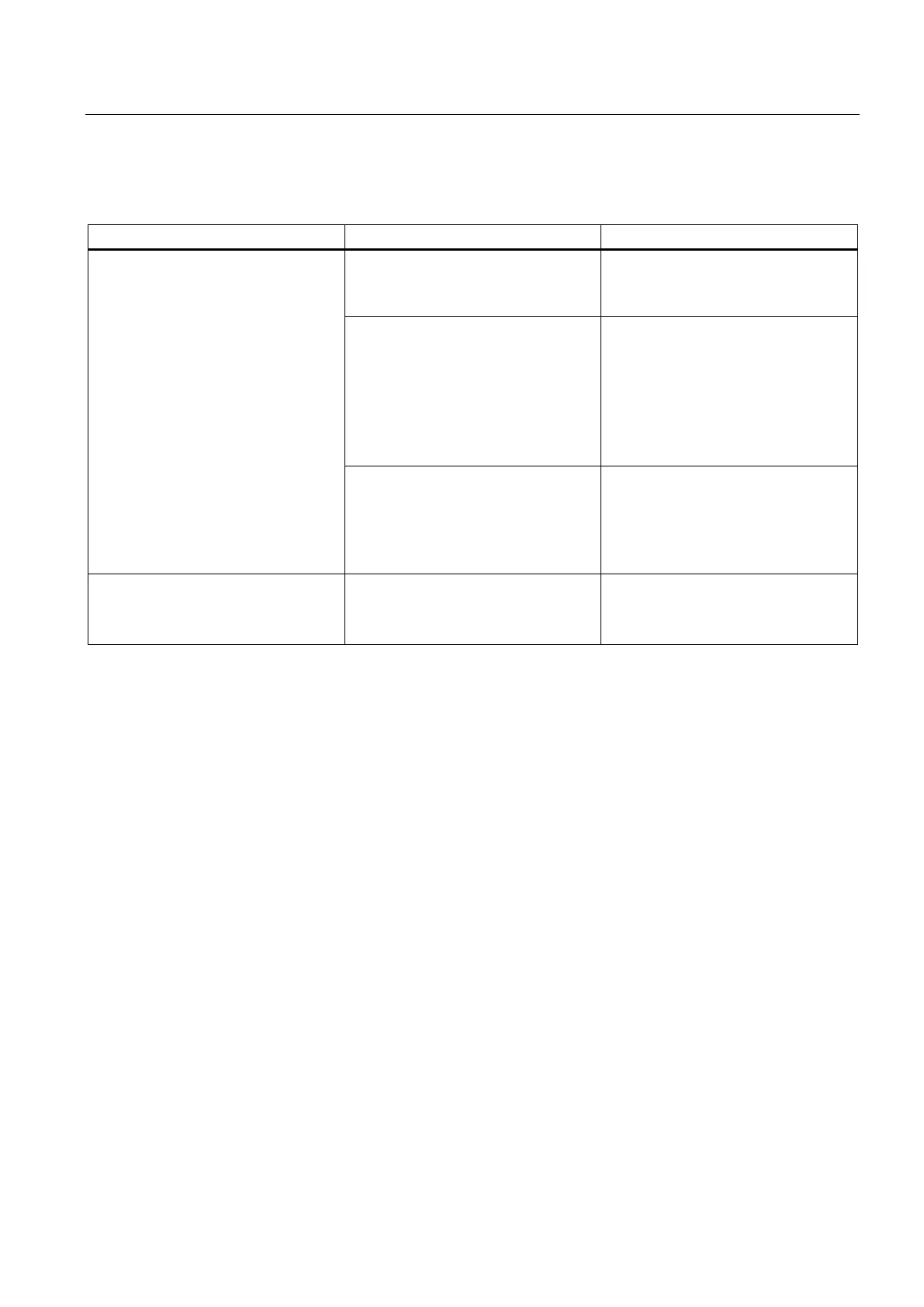

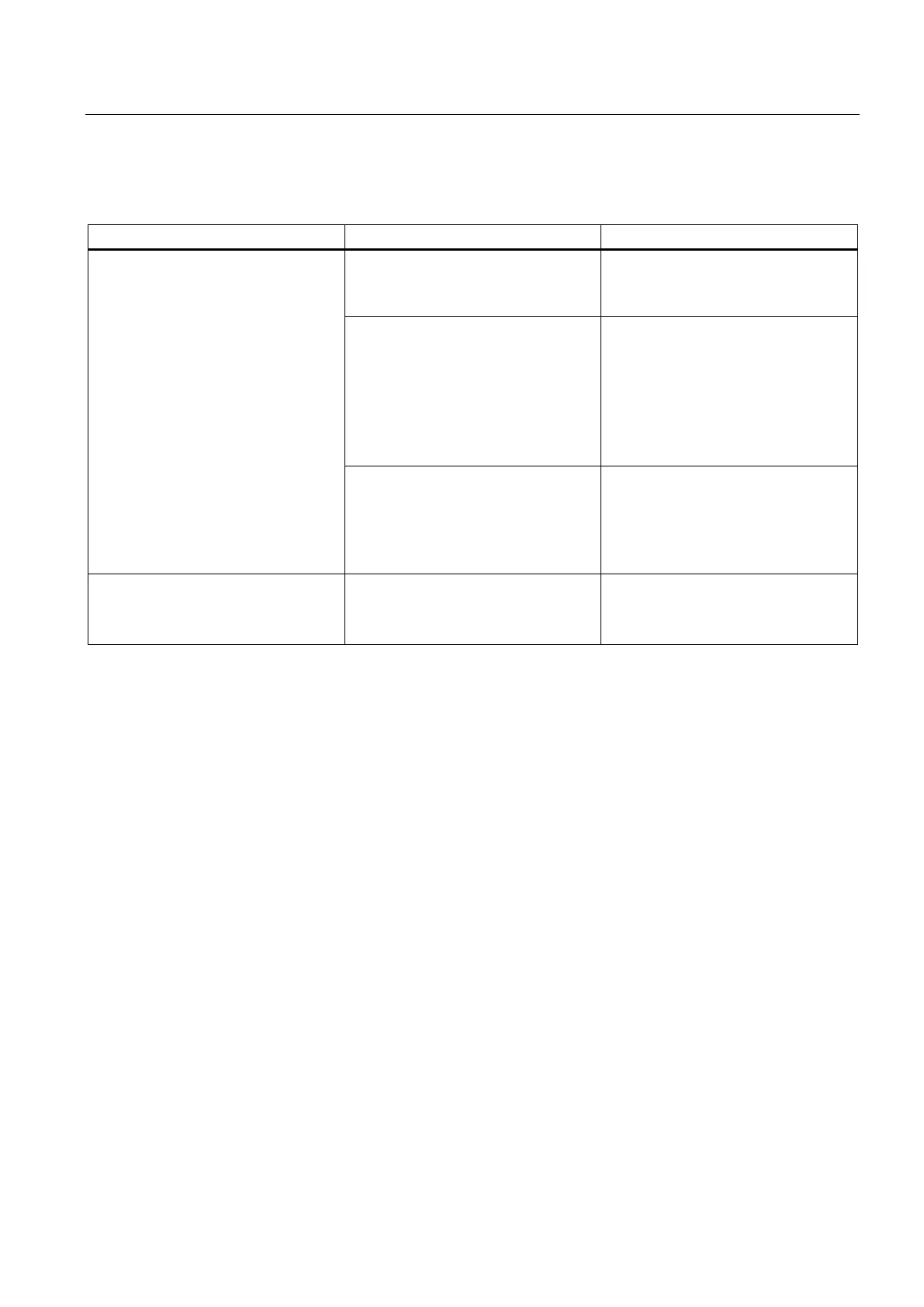

Remedial measures table 4

• In stationary automatic mode

(constant setpoint) and in manual

mode, both piezo valves continually

switch alternately, and the actuator

oscillates around a mean value.

• Sticking friction of the packing gland

from the control valve or actuator

too large

• Reduce friction or increase dead

zone of positioner (parameter

"dEbA") until the oscillation stops.

• Looseness (play) in the

positioner/actuator/control valve

system

• Part-turn actuator: Check for firm

seating of set screw on coupling

wheel.

• Linear actuator: Check for firm

seating of lever on positioner shaft.

• Correct any other play between the

actuator and the control valve.

• Actuator too fast • Increase actuating times using

throttle screws.

• If a quick actuating time is needed,

increase the dead zone (parameter

"dEbA") until the oscillation stops.

• Positioner doesn't move control

valve to the stop (at 20 mA).

• Supply pressure too low. Load on

the feeding controller or system

output is too low.

• Increase supply pressure, insert

ballast converter

• Select 3/4-wire mode

Cleaning of the screens (Page 232)

Loading...

Loading...