Alarm, error, and system messages

10.3 Online diagnostics

SIPART PS2 with and without HART

220 Operating Instructions, 10/2013, A5E00074631-11

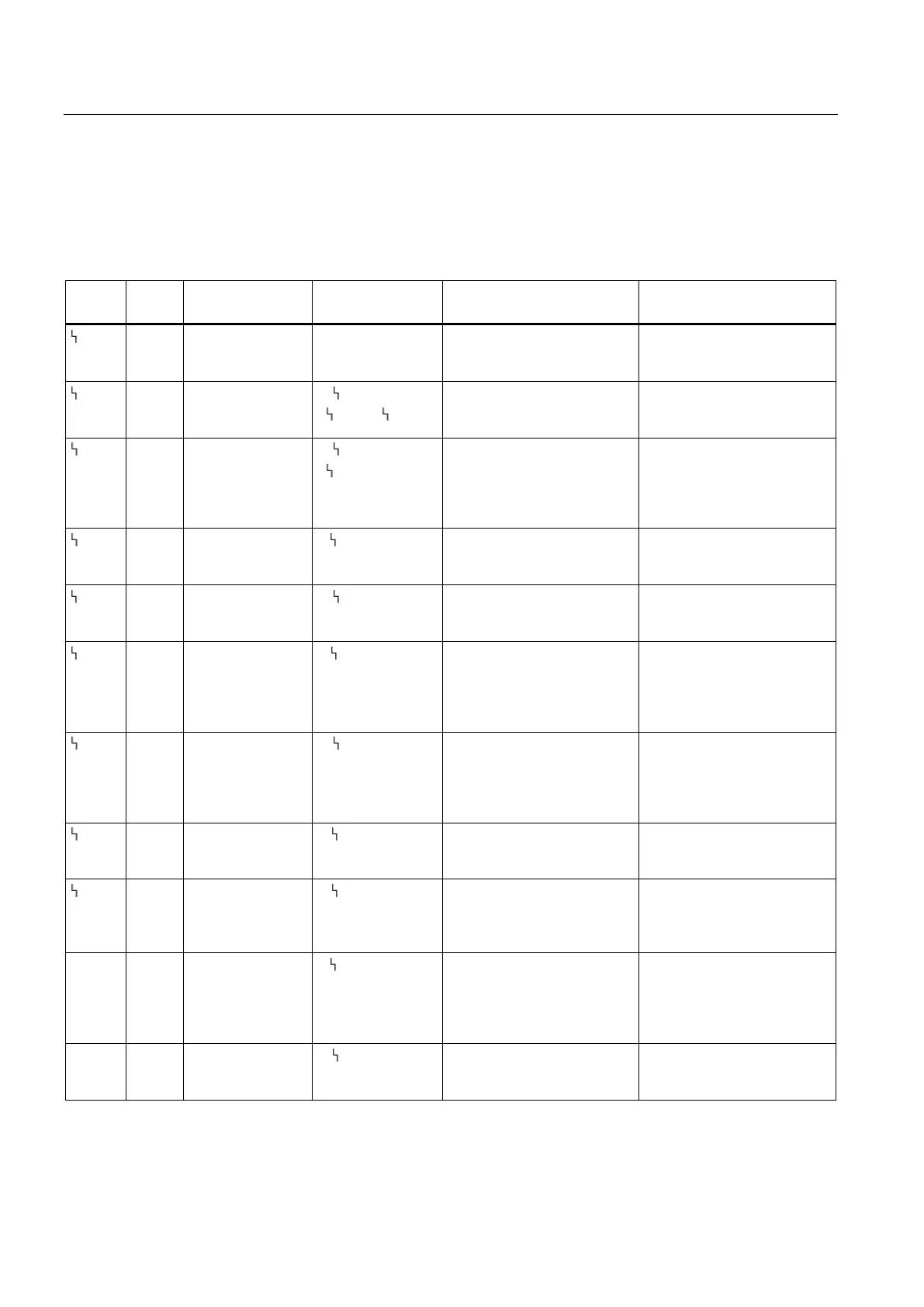

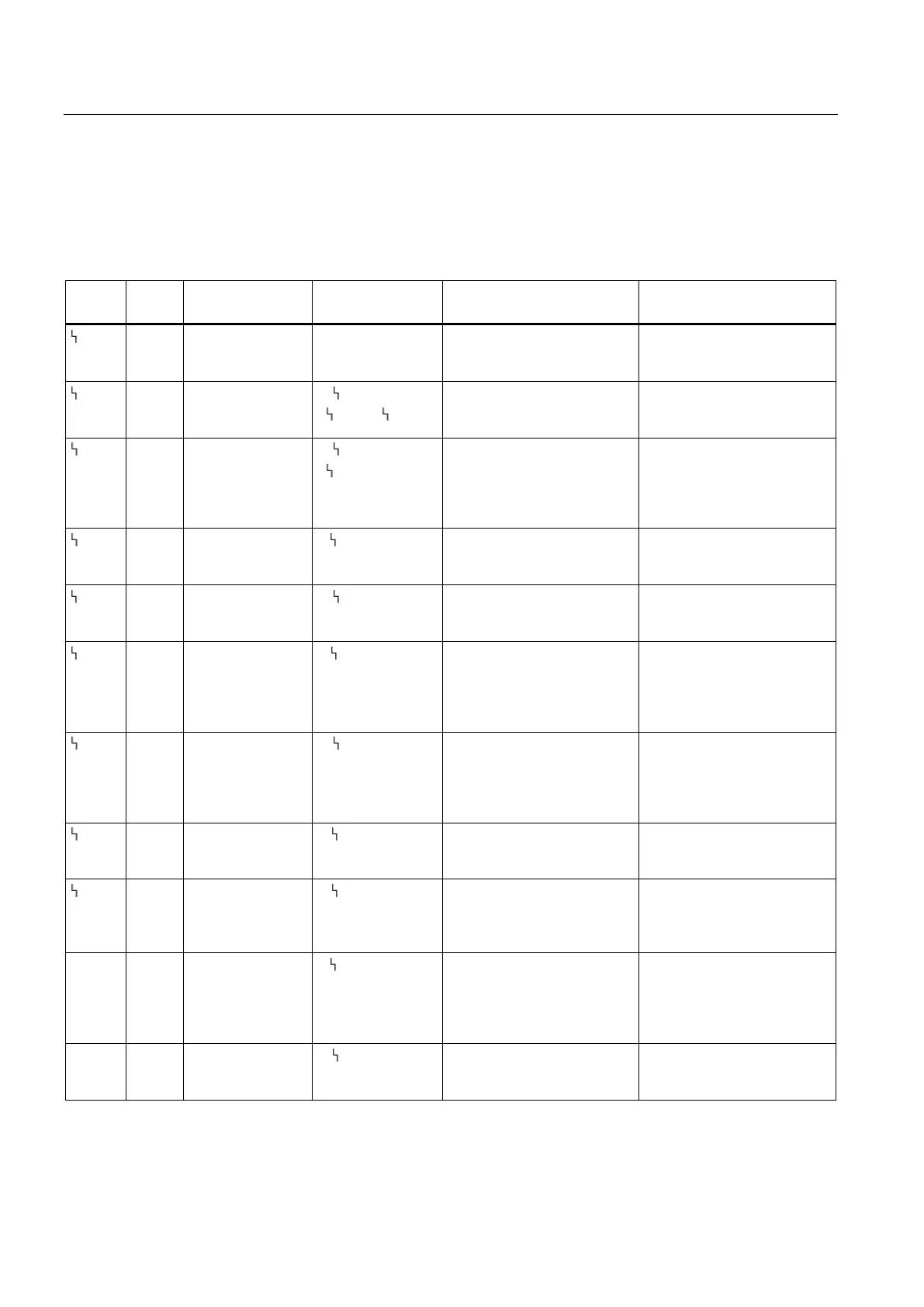

Overview of error codes

Overview of error codes that activate the fault message output

Error message disappears

when

1 No Remaining control

deviation

Always active ... the control deviation

disappears again.

Compressed air failure,

actuator fault, valve fault (e.g.

2 No Device not in the

automatic mode

**. FCT

1)

=

nA or = nAB

... the device is switched to

the automatic mode.

The device has been

configured or is in the manual

3 No Binary input BE1

or BE2 active

**. FCT

1)

= nAB and binary

function BIN1 or

BIN2 on "On"

... the binary input is no

longer active.

The contact connected to the

binary input was active (e.g.

packing gland monitoring,

overpressure, temperature

4 Yes The limit of stroke

number exceeded

L. STRK≠OFF ... the stroke counter is reset

or the thresholds are

The total path covered by the

actuator exceeds one of the

5 Yes Limit of changes of

direction exceeded

O. DCHG≠OFF ... the counter for changes of

direction is reset or the

thresholds are increased.

The number of changes of

direction exceeds one of the

configured thresholds.

6 Yes Limit of the lower

hard end stop

exceeded

F. ZERO≠OFF

do

... the deviation of the end

stop disappears or the device

is re-initialized.

Wear and tear of the valve

seat, deposits or foreign

bodies in the valve seat,

mechanical misalignment,

7 Yes Limit of the upper

hard end stop

exceeded

G. OPEN≠OFF

**.YCLS

1)

= do or

up do

... the deviation of the end

stop disappears or the device

is re-initialized.

Wear and tear of the valve

seat, deposits or foreign

bodies in the valve seat,

mechanical misalignment,

8 No Limit of deadband

adjustment

E. DEBA≠OFF

**.DEBA

1)

= Auto

... the limit is undershot again

Increased packing gland

friction, mechanical gap in the

9 Yes Partial-Stroke-Test

exceeds reference

stroke time

A. PST≠OFF ... a Partial-Stroke-Test is

successfully executed within

the reference stroke time or

the function is deactivated.

Valve jams or has rusted,

increased friction

10 Yes General control

valve fault

b. DEVI≠OFF ... the position is again in a

narrow corridor between the

reference variable and the

model, or the function is

deactivated.

Actuator fault, valve fault,

valve jams, increased friction,

decreased compressed air

11 Yes Pneumatic

leakage

C. LEAK≠OFF ... the leakage drops below

the configured thresholds, or

the function is deactivated.

Pneumatic leakage

Loading...

Loading...