Page 161

31.1.2 Back-up alarm speaker test

Step 2. Verify that a beep is sounded every time a

parameter control is pressed (O

2

%).

31.1.3 Setting O

2

%

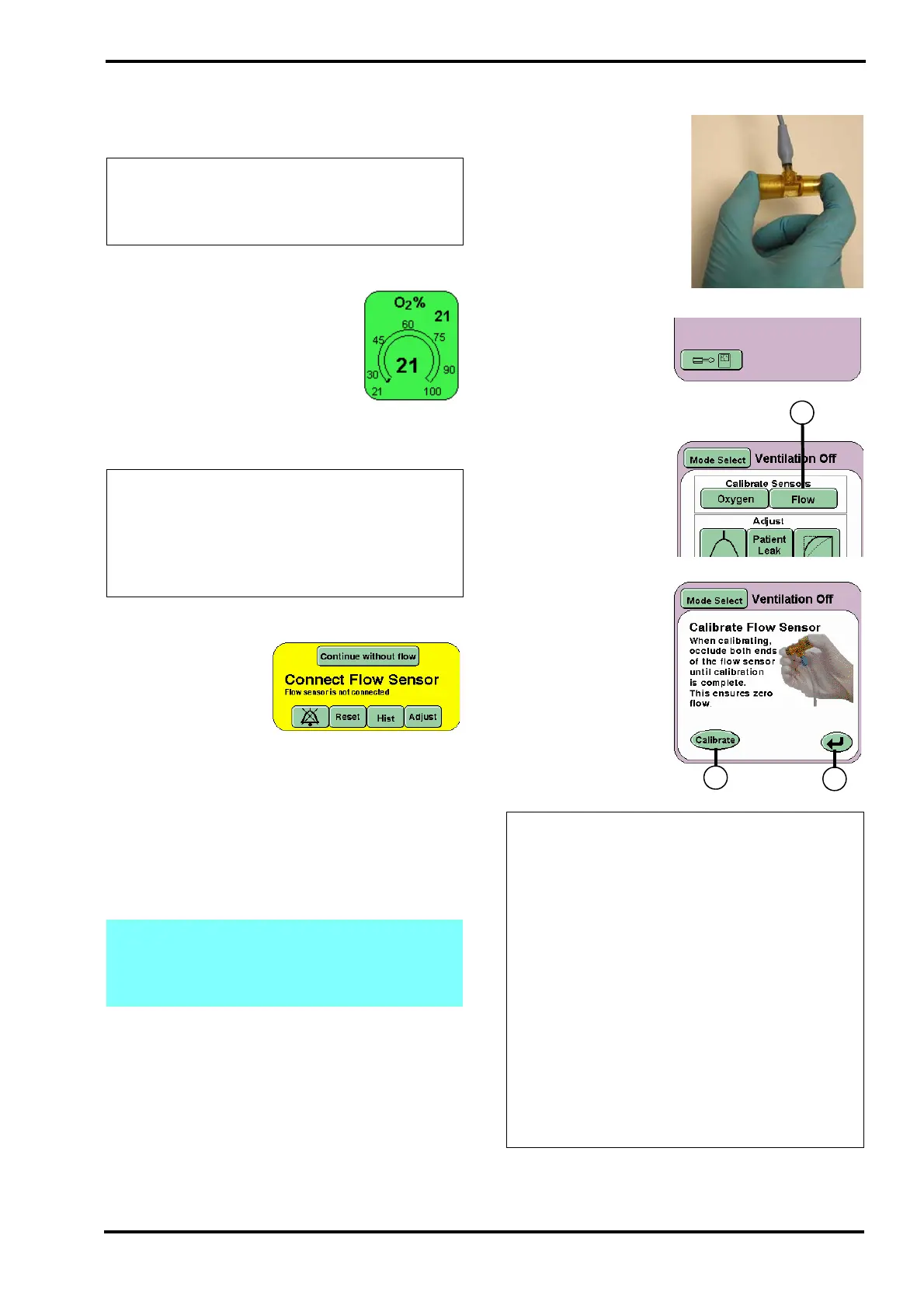

Step 3. In the Ventilation OFF mode

select the O

2

% parameter and

using the arrow keys set the value

to 21%. The ventilator defaults to

21% on start up.The measured

value will be displayed once the O

2

cell has finished its self calibration

routine. When finished, the set value and measured

value should correspond.

31.1.4 Functional Testing without a Flow Sensor

Step 4. If the ventilator

is to be used without a

flow sensor fitted,

then press the

“Continue without

flow” button in the

alarm panel.

If the “Continue without flow” button does not

display when a flow sensor is NOT fitted remove

ventilator from service and contact an SLE

approved engineer

Fit a test lung to the ET manifold.

The user should now advance to section 31.1.6

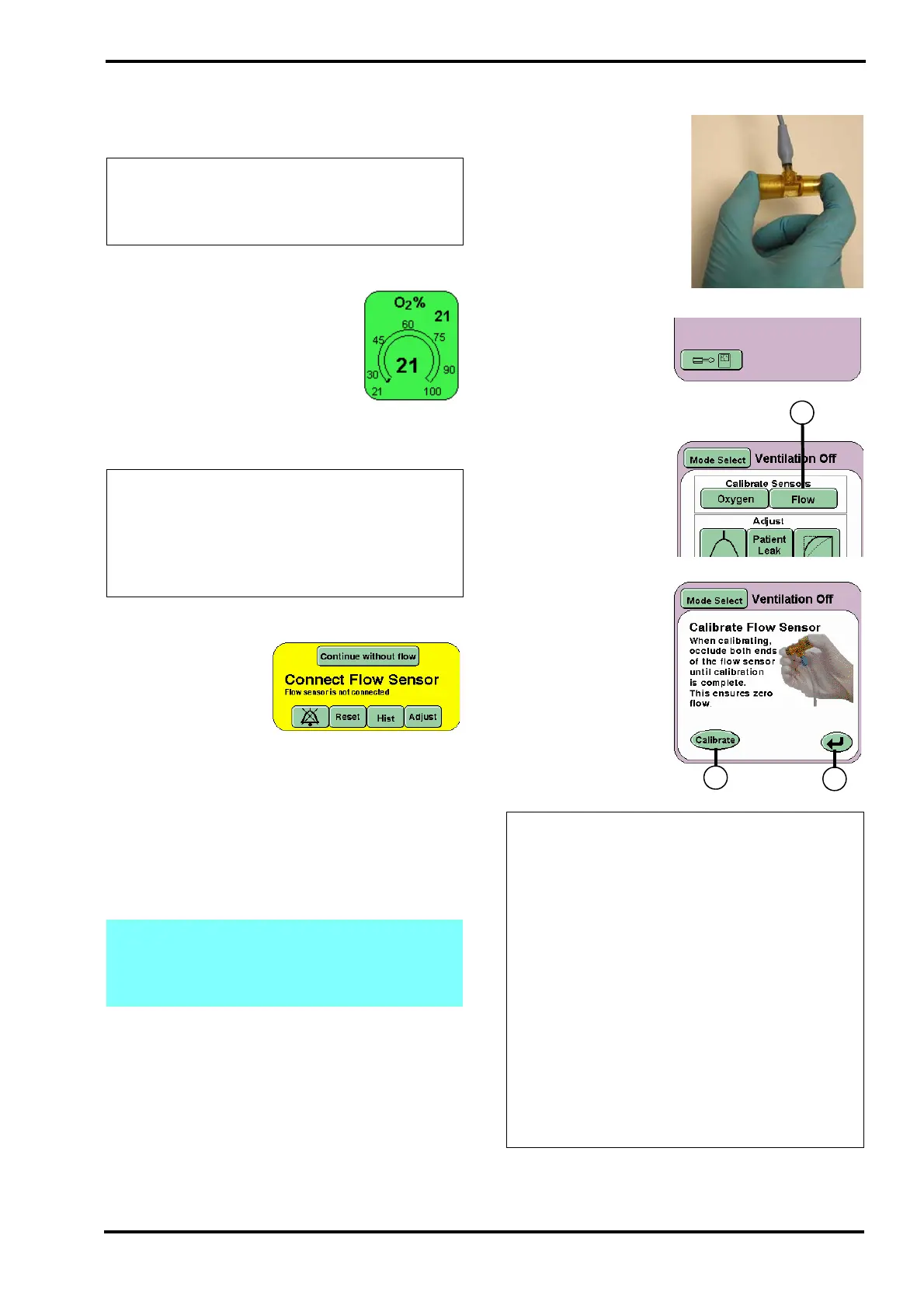

31.1.5 Calibration of the Flow sensor

Step 5. Make sure that

there is no flow passing

through the sensor. For

this purpose, occlude the

flow sensor by holding it

between two fingers,

closing both ends as

shown in the following

picture.

Press the Options and

Service Data button.

From the services

panel press the Flow

button (A)

With the flow sensor

now occluded press

the Calibrate button

(B). This initiates the

calibration cycle for

the flow sensor. Keep

the sensor occluded

until the words

“Calibration

Complete” appears

above the Calibrate

button.

The sensor has now been calibrated and can be

fitted into the patient circuit.

Action: If the beep fails to sound do not use

the ventilator on a patient. Remove ventilator

from service and contact an SLE approved

engineer.

Action: If the values do not correspond

perform a two point oxygen sensor

calibration (See “Two Point O

2

Calibration” on

page 126). If the fault continues after

calibration remove ventilator from service

and contact an SLE approved engineer.

Note: The functional testing routines have

been written with the flow sensor fitted. The

user will be told to skip a section if it applies

to testing a flow related function.

Action: If the flow sensor fails to calibrate

then perform the following actions in the

order suggested below. If the action involves

replacing a part then perform a re-calibration

after that action. If the flow sensor calibrates

successfully after performing one of these

actions carry on the remainder of this test

from the point where the flow sensor can be

fitted to the patient circuit.

• Replace the flow sensor cable

• Repeat calibration process with both ends

of flow sensor occluded

• Replace the flow sensor

If the fault continues after re-calibration

remove ventilator from service and contact an

SLE approved engineer.

Loading...

Loading...